Solid acid catalyst and preparation method thereof

A solid acid catalyst and catalyst technology, applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as easy loss, difficult catalysts, and catalyst deactivation, so as to maintain drug efficacy and be suitable for Industrial application, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

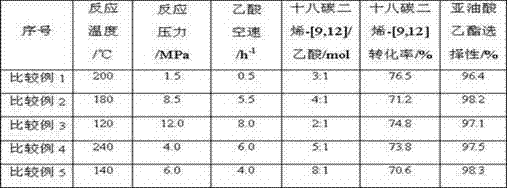

[0023] Prepare Zr(NO 3 ) 4 ·5H 2 O and Al (NO 3 ) 3 9H 2 O mixed aqueous solution, add ammonia water dropwise under stirring conditions until the pH value is 8-9 to form a white precipitate, after the precipitation is completed, increase the pH to 10-11 and age at room temperature for 24 hours, filter with suction, wash with water, and dry at 110°C for 12 hours to obtain ZrO 2 -Al 2 o 3 carrier. The carrier was immersed in sulfuric acid solution for 60 minutes, evaporated to dryness, and then placed in NH 4 VO 3 Equal volume impregnated in the solution, dried, and then baked at 600°C for 4 hours to obtain V 2 o 5 -SO 4 2- / ZrO 2 -Al 2 o 3 catalyst. By changing Zr(NO 3 ) 4 ·5H 2 O, Al (NO 3 ) 3 9H 2 The amount of O added, sulfuric acid solution, NH 4 VO 3 The concentration of the solution makes the composite solid superacid V of different mass percentages 2 o 5 -SO 4 2- / ZrO 2 -Al 2 o 3 A series of catalysts, see Table 1 for details.

[00...

Embodiment 1

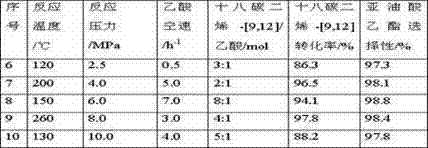

[0027] Application of the catalyst prepared in Examples 1-5 in the synthesis of ethyl linoleate. At the top and bottom of a stainless steel fixed bed reactor with a size of Φ18mm×1200mm, quartz sand with a diameter of Φ0.5mm to 1.2mm is respectively loaded, and 30ml of the above-mentioned formed V is filled in the middle. 2 o 5 -SO 4 2- / ZrO 2 -Al 2 o 3 After the catalyst is replaced by nitrogen three times, after the airtightness is qualified, octadecadiene-[9,12] and acetic acid are sent to the preheater according to the prescribed ratio by the metering pump, and the preheated reaction materials enter the fixed bed The reactor was reacted, and its reaction conditions and long-term operation 1000h reaction results are shown in Table 2, wherein serial numbers 6-10 are the catalysts prepared in Examples 1-5, for example, serial number 6 represents the catalyst prepared in Example 1.

[0028] Table 2

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com