High temperature resistance acid-proof alkali-proof coating

A technology of acid and alkali resistance, high temperature resistance, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., to achieve good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

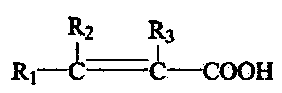

Method used

Image

Examples

Embodiment 1

[0013] Add 200 mL of ethanol, 1 g of vinyltrimethoxysilane, and 20 g of acrylic acid into a 500 mL three-necked flask, stir, and when the temperature rises to 70 °C, add 0.15 g of azobisisobutyronitrile, react for 5 h, and add 12 gNaOH, and continue stirring for 3 h to obtain silicone-modified sodium polyacrylate resin.

[0014] The coating formulation is shown in Table 1.

[0015] Table 1

[0016] materials Mass percentage / % nano silicon oxide 18 Silicone modified sodium polyacrylate 18 Formed substance 29 Forming Auxiliary 7 Accelerator 4 solvent 11 filler 4 acid 9

[0017] The prepared high-temperature-resistant, acid-resistant and alkali-resistant coating is applied by conventional construction methods such as brushing, wiping, manual roller construction, air spray gun or airless spray gun spraying, electrostatic spraying, thermal spraying, roller coating or dip coating. Its properties are shown in Table 2. ...

Embodiment 2

[0021] Add 200 mL of ethanol, 0.5 g of allyltrimethoxysilane, and 25 g of methacrylic acid into a 500 mL three-necked flask, stir, and when the temperature rises to 70 °C, add 0.15 g of azobisisoheptanonitrile and react for 8 h. Add 10 g of NaOH to the flask and continue to stir for 2 h to obtain the silicone-modified sodium acrylate resin.

[0022] The paint formulations are shown in Table 3.

[0023] table 3

[0024] materials Mass percentage / % nano silicon oxide 19 Silicone modified sodium polyacrylate 19 Formed substance 25 Forming Auxiliary 7.5 Accelerator 4 solvent 13 filler 5 acid 7.5

[0025] The prepared high-temperature-resistant, acid-resistant and alkali-resistant coating is applied by conventional construction methods such as brushing, wiping, manual roller construction, air spray gun or airless spray gun spraying, electrostatic spraying, thermal spraying, roller coating or dip coating. I...

Embodiment 3

[0029] In a 500 mL three-neck flask, add 200 mL propylene glycol monomethyl ether, 1.5 g gamma -A mixture of methacryloxypropyltrimethoxysilane and vinyltriethoxysilane, 30 g of methacrylic acid, stirring, when the temperature rises to 70 °C, add 0.15 g of benzoyl peroxide, react for 5 h, Add 15g of NaOH to the flask and continue to stir for 3 h to obtain the silicone-modified sodium polyacrylate resin.

[0030] The coating formulation is shown in Table 5.

[0031] table 5

[0032] materials Mass percentage / % nano silicon oxide 20 Silicone modified sodium polyacrylate 20 Formed substance 20 Forming Auxiliary 8 Accelerator 4 solvent 16 filler 6 acid 6

[0033] The prepared high-temperature-resistant, acid-resistant and alkali-resistant coating is applied by conventional construction methods such as brushing, wiping, manual roller construction, air spray gun or airless spray gun spraying, electrostatic sprayin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com