Methods for preparing mono-component hybridized aqueous anti-icing coating material and coating layer thereof and application of coating material

An anti-icing and coating technology, applied in the fields of materials, chemistry, and chemical industry, can solve the problems of high energy consumption, low efficiency, and easy pollution of the environment, and achieve the effect of simple construction technology, simple process, and reduced roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

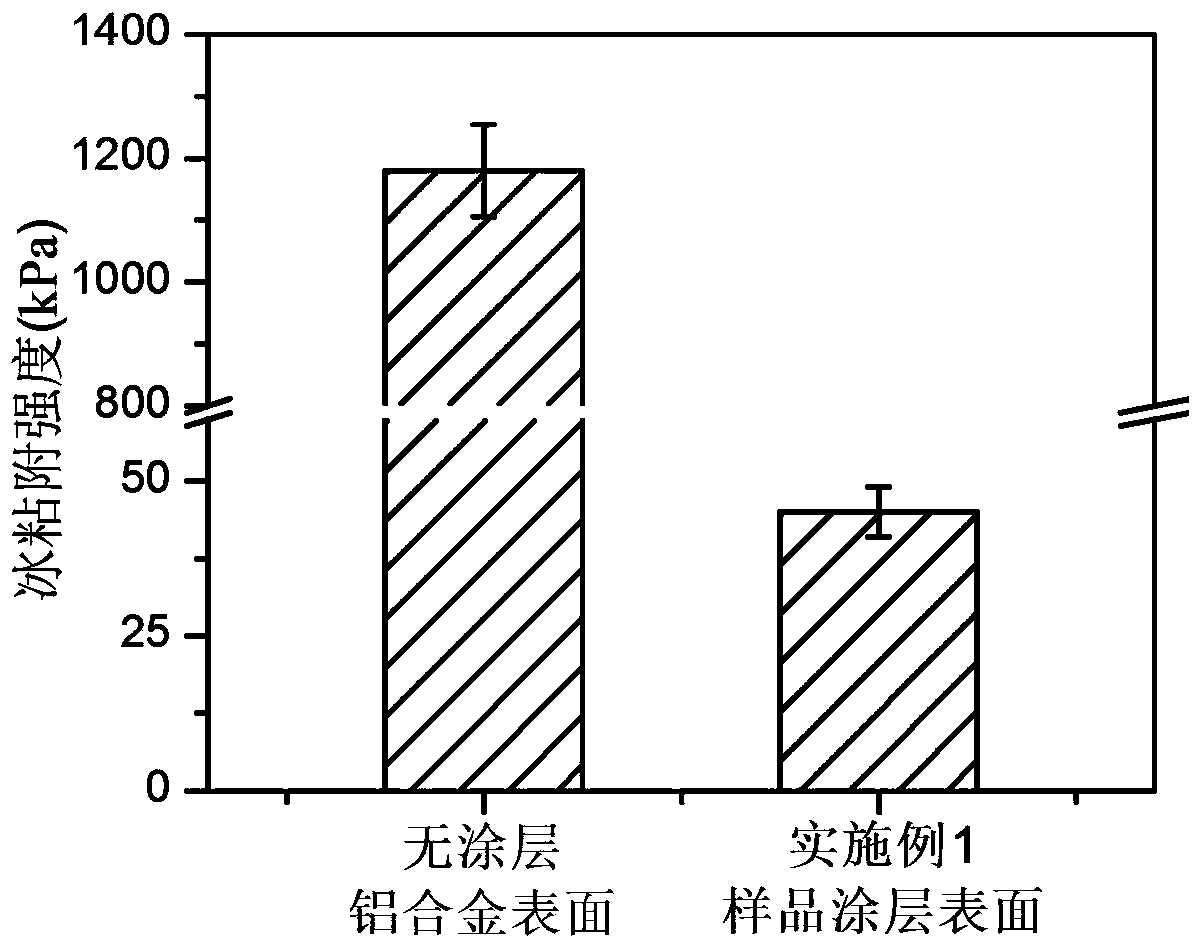

Embodiment 1

[0054] Example 2

[0055] (1) A certain quality of water-based epoxy-acrylate emulsion and an equivalent stoichiometric modified imidazole latent water-based curing agent are fully mixed evenly by a high-speed mixer.

Embodiment 2

[0057] (3) Apply the above-mentioned anti-icing coating to the surface of the aluminum alloy substrate by brushing, and solidify at 220° C. to form a film to obtain an anti-icing coating.

[0058] Example 3

[0059] (1) polyethylene adipate diol (M n =1000, 65g), isophorone diisocyanate (31g), dimethylolpropionic acid (6.7g) were added to a three-necked flask, heated to 80°C and stirred, and reacted to the content of -NCO group under nitrogen protection When the theoretical value is reached, add an appropriate amount of acetone according to the viscosity of the system to reduce the viscosity; add a stoichiometric blocking agent caprolactam, react at 80°C for 2 hours to block -NCO, until the reaction of -NCO is basically complete; cool down to 40°C, add triethylamine (5g), and neutralized for 15 minutes to obtain a polyurethane prepolymer; by adjusting the stirring, the polyurethane prepolymer was dispersed in deionized water to obtain a cross-linkable and curable aqueous poly...

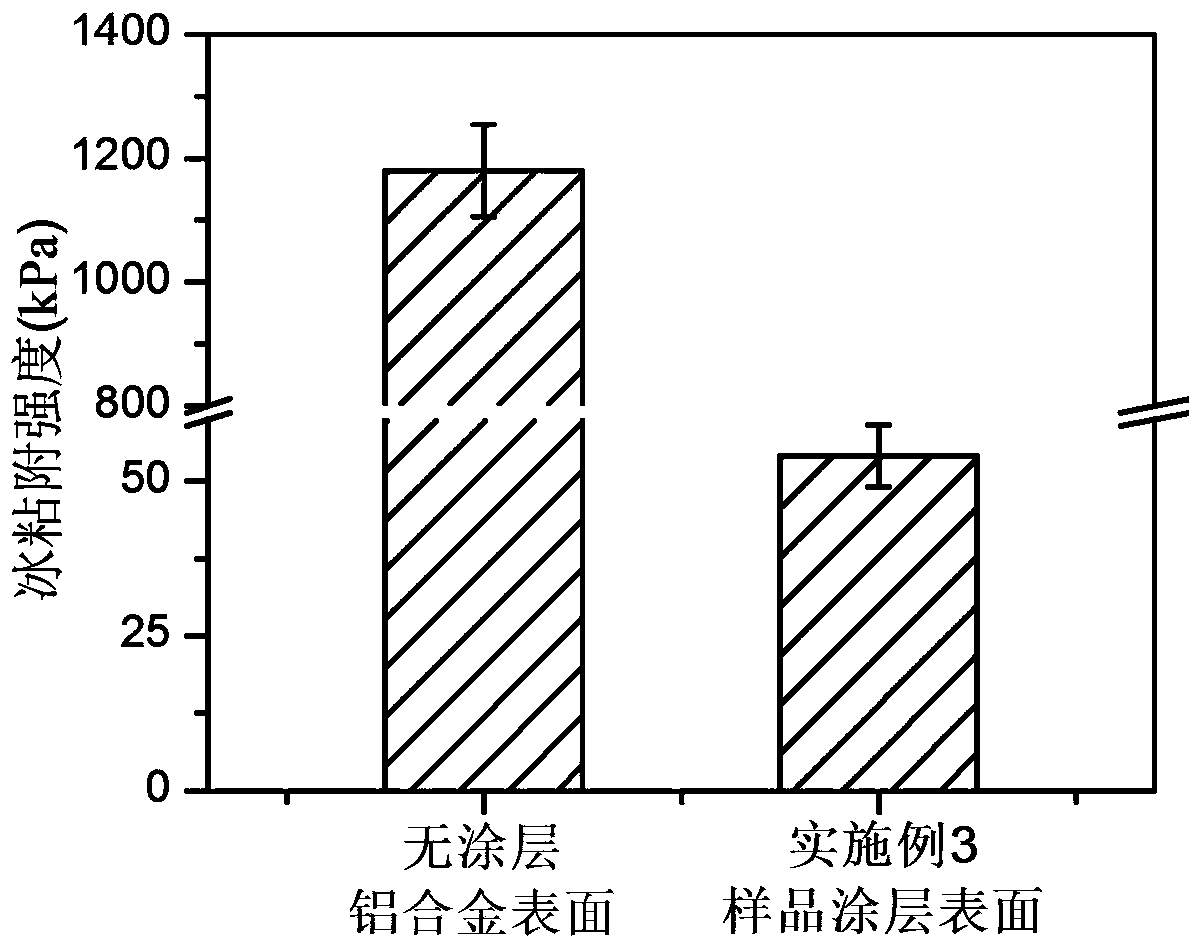

Embodiment 3

[0061] (3) Apply the above-mentioned anti-icing coating to the surface of the aluminum alloy substrate by brushing, and dry at 180°C to form a film to obtain an anti-icing coating.

[0062] Example 4

[0063] (1) Polyethylene glycol (M n =1000, 65g), toluene diisocyanate (26g) was added into a three-necked flask, heated to 80°C and stirred, and reacted under nitrogen protection for 2h; then added dimethylolpropionic acid (6.7g), reacted at 80°C for 2h; Cool down to 60°C, add hydroxyethyl methacrylate (1.5g) and hydroquinone (0.5g), react for 2h; cool down to 40°C, add triethylamine for neutralization reaction for 0.5h, to obtain polyurethane prepolymer ; By high-speed stirring, the polyurethane prepolymer is dispersed in deionized water to obtain a photocurable polyurethane emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com