Preparation method of casein keratinase crosslinked polymer membrane

A keratinase and heteropolymer technology, which is applied in the field of preparation of casein keratinase cross-linked heteropolymer films, can solve problems such as environmental problems and insufficient modification effect, and achieves reduced production costs, good water resistance, and hydrophobicity. Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

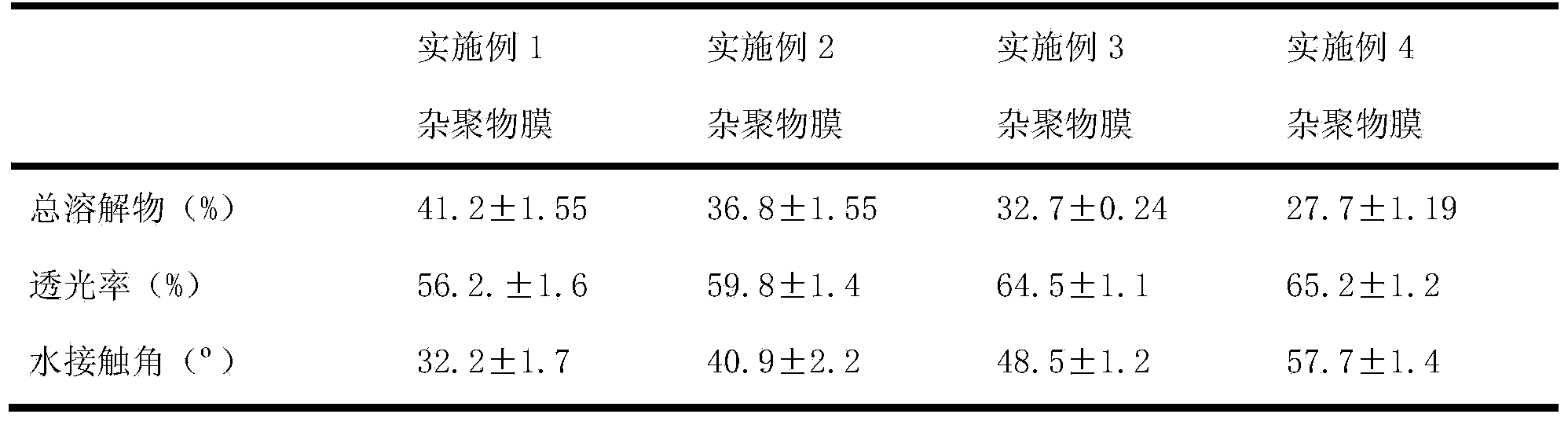

Embodiment 1

[0034] A preparation method of casein keratinase cross-linked heteropolymer film, comprising the following steps:

[0035] 1) Preparation of casein and keratin solution

[0036] Preparation of casein solution: Take 7g casein, 92g water and 1g5mol / L NaOH solution, immerse the casein in part of deionized water, add NaOH solution, mix well, soak continuously for more than 24 hours (continuously soak during this process) Add part of deionized water until the casein is completely soaked, and the pH value of the system is kept below 7.0); stir the casein at this time evenly, and add the remaining deionized water. The pH value of the solution is adjusted to 7.5, and the magnetic stirring is continued until completely dissolved to obtain a casein solution with a mass fraction of 7%;

[0037] Preparation of keratin solution: Add 7g of keratin powder into 93g of deionized water, mix well, adjust the pH value of the system to 9.0 with solid NaOH, and stir magnetically for 3 hours at 50°...

Embodiment 2

[0045]A preparation method of casein keratinase cross-linked heteropolymer film, comprising the following steps:

[0046] 1) Preparation of casein and keratin solution

[0047] Preparation of casein solution: Take 7g casein, 92g water and 1g5mol / L NaOH solution, immerse the casein in part of deionized water, add NaOH solution, mix well, soak continuously for more than 24 hours (continuously soak during this process) Add part of deionized water until the casein is completely soaked, and the pH value of the system is kept below 7.0); stir the casein at this time evenly, and add the remaining deionized water. The pH value of the solution is adjusted to 7.5, and the magnetic stirring is continued until completely dissolved to obtain a casein solution with a mass fraction of 7%;

[0048] Preparation of keratin solution: Add 7g of keratin powder into 92.5g of deionized water, mix well, add 0.5g of solid NaOH to adjust the pH value of the system to 9.0, and stir magnetically for 4 h...

Embodiment 3

[0056] A preparation method of casein keratinase cross-linked heteropolymer film, comprising the following steps:

[0057] 1) Preparation of casein and keratin solution

[0058] Preparation of casein solution: Take 7g of casein, 92g of water and 1g of 5mol / L NaOH solution, immerse the casein in part of deionized water, add NaOH solution, mix well, soak continuously for more than 12h (continuously add part of the deionized water until the casein is completely soaked and the pH value of the system is kept below 7.0); stir the casein evenly at this time, and add the remaining deionized water. The pH value of the solution is adjusted to 6.5, and the magnetic stirring is continued until it is completely dissolved to obtain a casein solution with a mass fraction of 7%;

[0059] Preparation of keratin solution: Add 7g of keratin powder into 92.5g of deionized water, mix well, add 0.5g of solid NaOH to adjust the pH of the system to 9.0, and stir magnetically for 0.5h at 55°C until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com