Preparation method of hydrocarbon conversion catalyst carrier

A technology for catalyst carrier and hydrocarbon conversion, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc., and can solve problems such as difficult to obtain a carrier with large pore volume and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

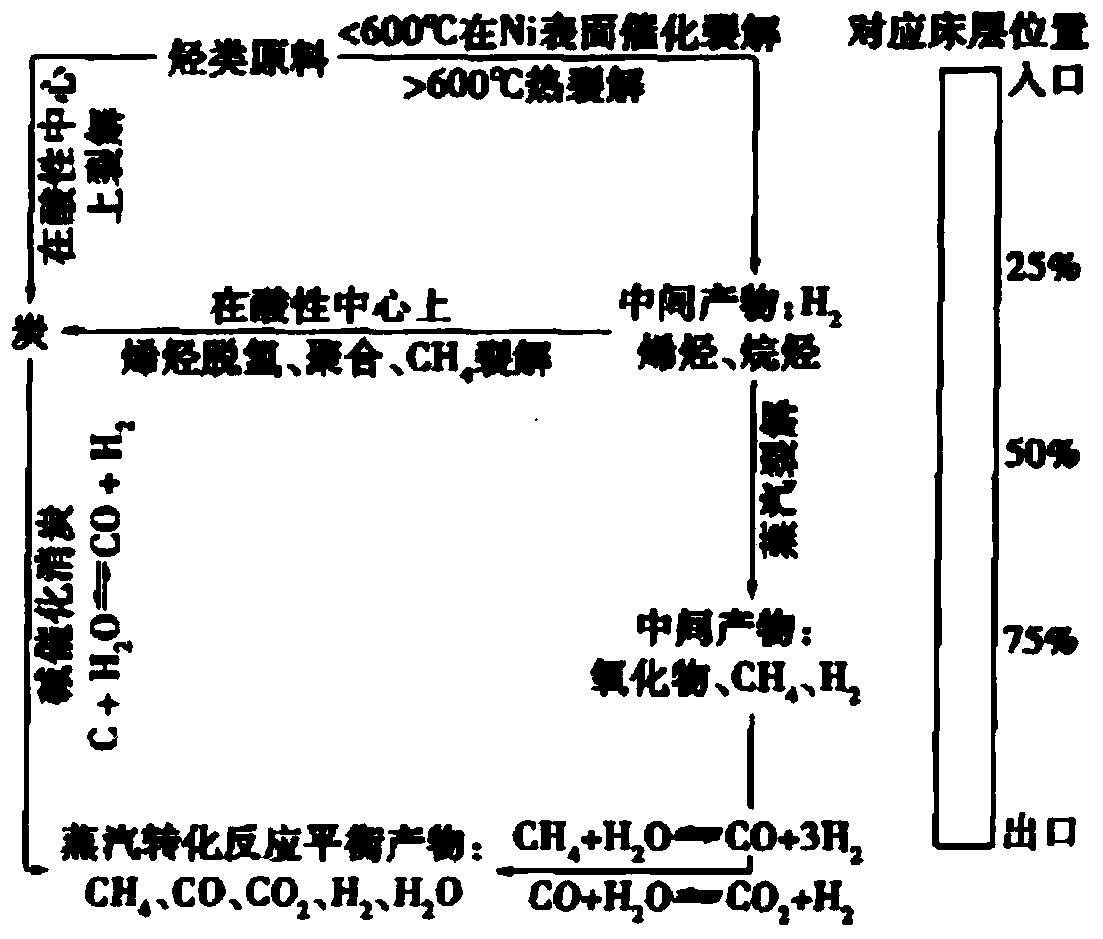

Method used

Image

Examples

Embodiment 1

[0039] A novel method for preparing a catalyst carrier for hydrocarbon conversion, using pseudo-boehmite as the initial material and adding the auxiliary agent WO 3 , Sodium polyethoxide (PVA) and magnesium carbonate are prepared by ball milling, water mixing, steam treatment and calcination. After the steam treatment and drying of the ball mill mixture, it is first calcined to 460°C, and at this time, the pseudo-boehmite has large pores with a pore diameter of 560nm. Then calcined to 800°C, the carbonate additive decomposes, and small pores are opened in the large pores with a pore diameter of 78nm to make a carrier with large pore volume and specific surface area. Finally, the calcination temperature rises to 1150°C to complete Al 2 o 3 The crystallization was carried out to obtain the final carrier. The measured pore volume is 0.30mL / g, and the specific surface area is 13m 2 / g, the bulk density of the carrier is 0.65kg / L.

Embodiment 2

[0041] A novel preparation method of hydrocarbon conversion catalyst carrier, using pseudo-boehmite as the initial material, adding additive MoO 3 , Methyl cellulose (MC) and strontium carbonate are prepared by ball milling, water mixing, steam treatment and calcination. After the steam treatment and drying of the ball mill mixture, it is first calcined to 650°C, at this time, the pseudo-boehmite has large pores with a diameter of 100nm. Then calcined to 900°C, the carbonate additive decomposes, and small pores are opened in the large pores with a pore diameter of 500nm to make a carrier with large pore volume and specific surface area. Finally, the calcination temperature rises to 1350°C to complete Al 2 o 3 The crystallization was carried out to obtain the final carrier. The measured pore volume is 0.45mL / g, and the specific surface area is 20m 2 / g, the bulk density of the carrier is 0.635kg / L.

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com