Preparation method of biologically degradable thermoplastic polyurethane elastomer

A thermoplastic polyurethane and elastomer technology, applied in the field of preparation of biodegradable thermoplastic polyurethane elastomer, can solve the problems of high cost, secondary pollution, long degradation cycle, etc., and achieve the advantages of avoiding pollution, high modulus and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

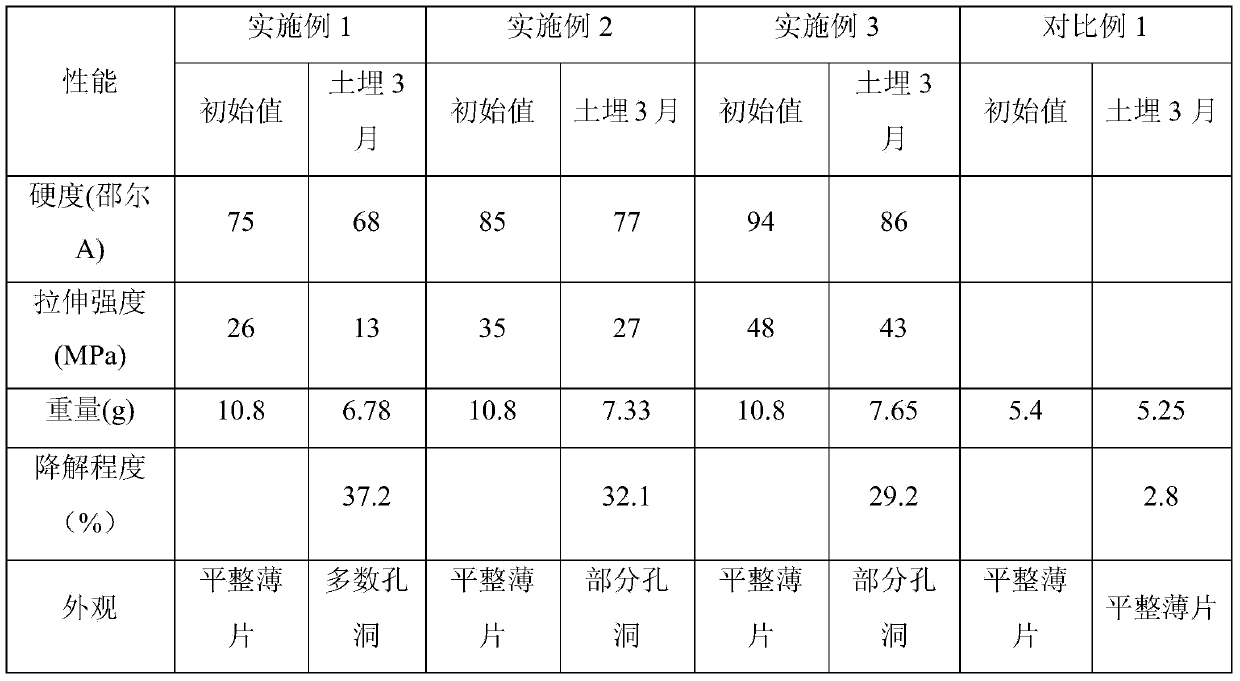

[0016] Preparation of biodegradable thermoplastic polyurethane elastomer: by weight, polybutylene adipate diol (PBA2000, M=2000): 240g, polycaprolactone diol (PCL2000): 60g, diphenylmethane Diisocyanate (MDI): 87.2g, 1,4-Butanediol (BDO): 18.2g, Isocyanate Index r 0 =0.99. Dehydrate PBA2000 at 110°C for 2 hours, then lower the temperature to 80°C, add BDO, mix well, add MDI and mix and stir for 15s, inject it into the mold, press it into a 1mm TPU sheet in a 100°C flat vulcanizer, and keep it at 100°C for vulcanization 4h, and then placed in a blast oven for 8h at 80°C. Embed the prepared TPU flakes in the sludge with a depth of about 15 cm and an ambient temperature of 25°C. After 3 months, take out the test weight loss and observe the appearance of the thin slice, and express the degree of degradation with the thin slice weight loss rate. The results are shown in Table 1.

Embodiment 2

[0018] According to the preparation method of embodiment 1.

[0019] Preparation of biodegradable thermoplastic polyurethane elastomer: measured by weight, PBA2000: 240g, PCL2000: 60g, MDI: 128.4g, BDO: 33.2g.

[0020] The results of antimicrobial performance of TPU buried in soil are shown in Table 1.

Embodiment 3

[0022] According to the preparation method of embodiment 1.

[0023] Preparation of biodegradable thermoplastic polyurethane elastomer: measured by weight, PBA2000: 240g, PCL2000: 60g, MDI: 189.9g, BDO: 55.6g.

[0024] The results of antimicrobial performance of TPU buried in soil are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com