A kind of cu-ni-al-ce porous alloy and preparation method thereof

A cu-ni-al-ce, alloy technology, applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the problem of low mechanical properties and creep properties of sintered bodies, difficulty in meeting the performance requirements of anode materials, and the decline in MCFC performance, etc. problems, to achieve the effect of industrialized large-scale production, good cohesion, and no macro-segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A Cu-Ni-Al-Ce porous alloy of the present invention comprises the following components in mass fraction:

[0030] Ni25wt.%,

[0031] Al10wt.%,

[0032] Ce2wt.%, and

[0033] Cu balance.

[0034] A method for preparing the Cu-Ni-Al-Ce porous alloy of the above-mentioned present embodiment, comprising the following steps:

[0035] (1) Proportion the metal Cu, Ni, Al, and Ce with a purity greater than 99.8wt.% according to the above mass fractions, then put Cu, Ni, Al, and Ce in a melting furnace and mix and heat to a molten state. After stirring, a Cu-Ni-Al-Ce alloy liquid is obtained;

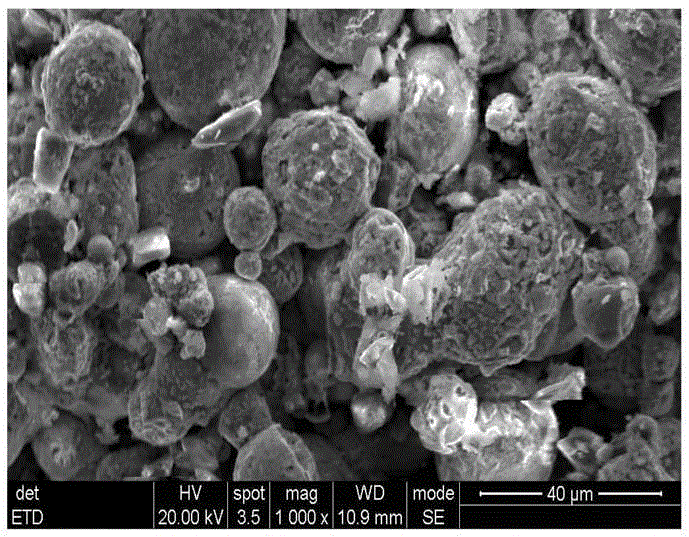

[0036] (2) Pour the Cu-Ni-Al-Ce alloy liquid into the crucible of an atomization rapid condensation device (the device includes an atomization spray gun), and use the atomization rapid condensation device to atomize and make powder, and the liquid flow of the alloy liquid The rate is 0.85kg / min, the atomization medium is N 2 , the atomizing gas flow pressure is 0.8MPa (ie N 2Pressu...

Embodiment 2

[0041] A Cu-Ni-Al-Ce porous alloy of the present invention comprises the following components in mass fraction:

[0042] Ni25wt.%,

[0043] Al15wt.%,

[0044] Ce4wt.%, and

[0045] Cu balance.

[0046] A method for preparing the Cu-Ni-Al-Ce porous alloy of the above-mentioned present embodiment, comprising the following steps:

[0047] (1) Proportion the metal Cu, Ni, Al, and Ce with a purity greater than 99.8wt.% according to the above mass fractions, then put Cu, Ni, Al, and Ce in a melting furnace and mix and heat to a molten state. After stirring, a Cu-Ni-Al-Ce alloy liquid is obtained;

[0048] (2) Pour the Cu-Ni-Al-Ce alloy liquid into the crucible of an atomization rapid condensation device, and use the atomization rapid condensation device to atomize and make powder. The flow rate of the alloy liquid is 0.65kg / min. Change the medium to N 2 , the atomizing gas flow pressure is 0.85MPa (ie N 2 Pressure), the diameter of the atomizing nozzle of the atomizing spray ...

Embodiment 3

[0053] A Cu-Ni-Al-Ce porous alloy of the present invention comprises the following components in mass fraction:

[0054] Ni35wt.%,

[0055] Al15wt.%,

[0056] Ce4wt.%, and

[0057] Cu balance.

[0058] A method for preparing the Cu-Ni-Al-Ce porous alloy of the above-mentioned present embodiment, comprising the following steps:

[0059] (1) Proportion the metal Cu, Ni, Al, and Ce with a purity greater than 99.8wt.% according to the above mass fractions, then put Cu, Ni, Al, and Ce in a melting furnace and mix and heat to a molten state. After stirring, a Cu-Ni-Al-Ce alloy liquid is obtained;

[0060] (2) Pour the Cu-Ni-Al-Ce alloy liquid into the crucible of an atomization rapid condensation device, and use the atomization rapid condensation device to atomize and make powder. The flow rate of the alloy liquid is 0.50kg / min. Change the medium to N 2 , the atomizing gas flow pressure is 0.95MPa (ie N 2 pressure), the diameter of the atomizing nozzle of the atomizing spray ...

PUM

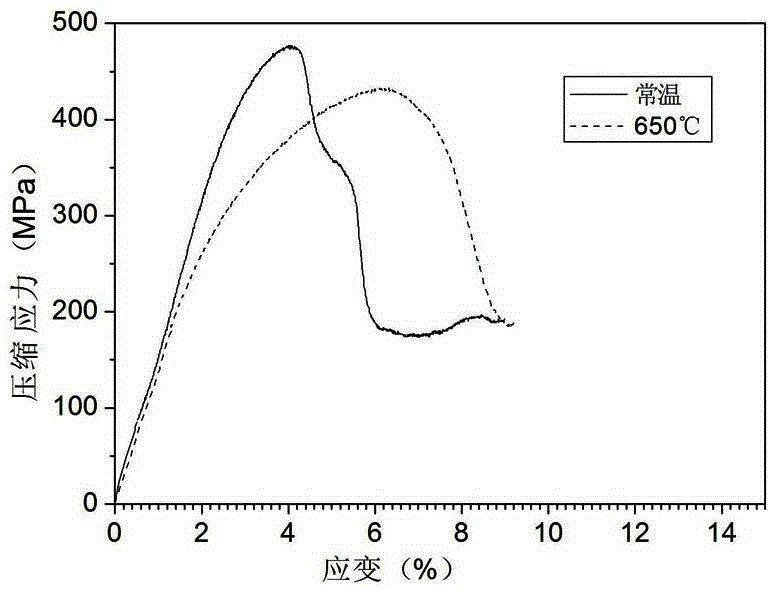

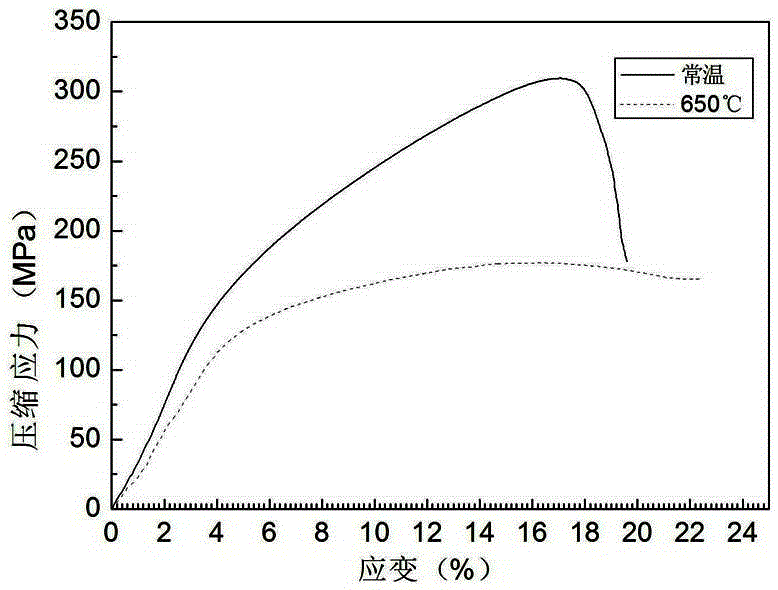

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com