Method for performing microwave arsenic removal on high-arsenic iron ore

An arsenite and microwave technology, which is applied in the field of microwave dearsenic through high arsenite, can solve problems such as being unsuitable for large-scale industrial production of iron and steel, and achieve the effects of shortening roasting time, flexible operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

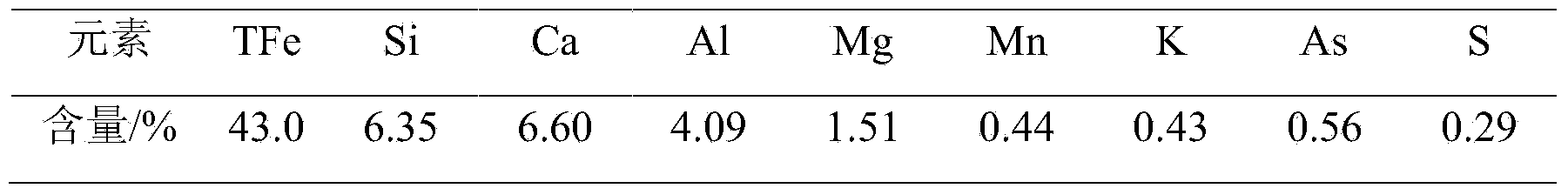

[0020] This example uses arsenic-containing iron ore from a mine in Inner Mongolia. The ore composition is shown in Table 1. The raw material added is coal powder. The specific implementation steps are as follows:

[0021] Table 1 Elemental composition of an iron ore in Inner Mongolia (%)

[0022]

[0023] 1) Take 500g of arsenic-containing iron ore, grind it to less than 1mm, add coal powder according to 5% of the mass of arsenic-containing iron ore, mix evenly, and put it into a corundum crucible.

[0024] 2) Put the crucible in a microwave oven and bake at a temperature of about 950°C for 10 minutes. After cooling, send the sample to an atomic fluorescence analyzer for analysis. It is obtained that the As content in the sample after roasting is 0.053%, and the arsenic removal rate is 90.54%, the same ratio, the same conditions in the muffle furnace roasting arsenic removal rate is only 80.14%.

[0025] 3) Arsenic-containing tail gas enters the tail gas collection device...

Embodiment 2

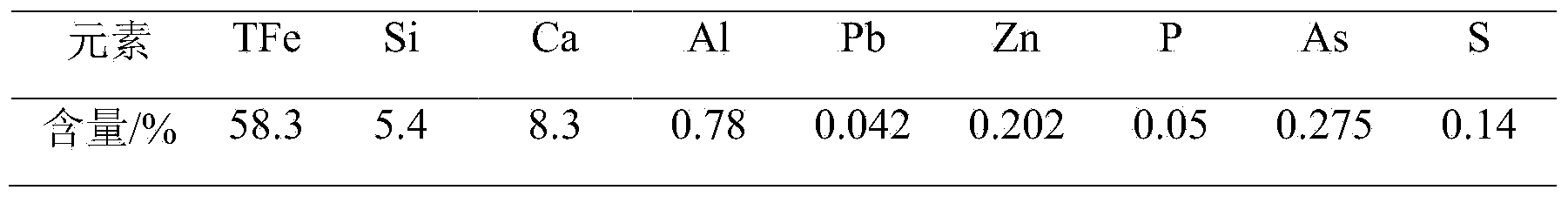

[0027] What this example selects is the arsenic-containing iron ore of a certain mine in Guangxi. The ore composition is shown in Table 2, and the raw material added is coal powder.

[0028] Table 2 Elemental composition table of an iron ore in Guangxi (%)

[0029]

[0030] 1) Take 500g of arsenic-containing iron ore, grind it to less than 1mm in a vibration mill, add carbon powder according to 6% of the mass of arsenic-containing iron ore, mix evenly, and put it into a corundum crucible.

[0031] 2) Put the crucible in a microwave oven and roast it at a temperature of about 1000°C for 15 minutes. Send the roasted sample to an atomic fluorescence analyzer for analysis. It is obtained that the As content in the roasted sample is 0.02%, and the arsenic removal rate is 92.73%, the effect is remarkable.

[0032] 3) Arsenic-containing tail gas enters the tail gas collection device to reduce environmental pollution.

Embodiment 3

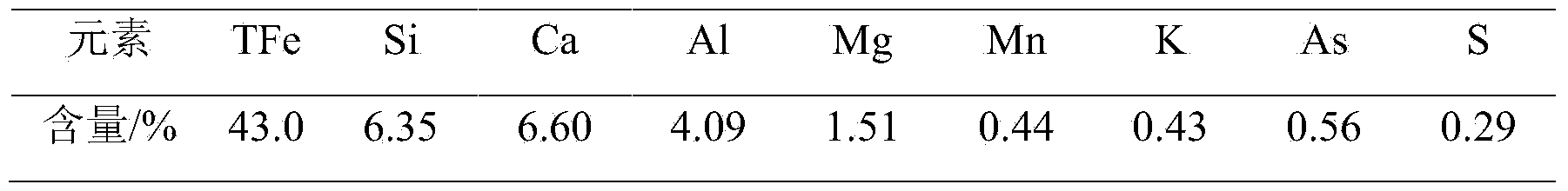

[0034] This example selects arsenic-containing iron ore from a mine in Inner Mongolia. The ore composition is shown in Table 3, and the added raw material is coal powder. The specific implementation steps are as follows:

[0035] Table 3 Element composition table of an iron ore in Inner Mongolia (%)

[0036]

[0037] 1) Take 500g of arsenic-containing iron ore, grind it to less than 1mm in a vibrating mill, add coal powder according to 8% of the mass of arsenic-containing iron ore, mix evenly, and put it into a corundum crucible.

[0038] 2) Put the crucible in a microwave oven and roast it at a temperature of about 1050°C for 20 minutes. Send the roasted sample to an atomic fluorescence analyzer for analysis. It is obtained that the As content in the roasted sample is 0.008%, and the arsenic removal rate is 98.57%, the effect is remarkable.

[0039] 3) Arsenic-containing tail gas enters the tail gas collection device to reduce environmental pollution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com