Surface modification fiber-reinforced composite bone cement as well as preparation method and application thereof

A surface modification and bone cement technology, applied in fiber processing, textile and papermaking, medical science, etc., can solve the problems of poor interfacial bonding strength, insufficient toughness and poor degradability of bone cement, and achieve high brittleness and good biological phase. Capacitive and biodegradable, strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of the surface modified polymer fiber of the present invention comprises the following steps:

[0070] (a) provide polymer fibers;

[0071] (b) performing plasma treatment on the surface of the polymer fiber to obtain a surface plasma treated polymer fiber;

[0072] (c) placing the surface plasma-treated polymer fiber obtained in step b) in a dopa solution for surface mineralization treatment to obtain the surface-modified polymer fiber.

[0073] In the present invention, a low-temperature plasma processor is preferably used for plasma treatment.

[0074] The atmosphere of the plasma treatment is O 2 , Ar, N 2 One or a mixture of several, wherein the preferred atmosphere is O 2 atmosphere.

[0075] The power of plasma treatment is 40w-1000w, preferably 300w-600w.

[0076] The plasma treatment time is 1-600s, preferably 10-120s.

[0077] The mineralization treatment refers to treating the surface of the polymer fiber with a dopa solution to ...

Embodiment 1

[0114] Put 1g of PLGA fiber (polylactic acid-glycolic acid copolymer) into the treatment chamber of the cold plasma treatment equipment, O 2 The degree of vacuum was adjusted to 20 Pa under the atmosphere. After the vacuum degree is stable, adjust the power to 600w, and adjust the discharge treatment time to 120s. Then the automatic matcher starts to work until the reflected power is adjusted to the minimum, then starts to discharge, and automatically turns off the glow after the time is up. After the vacuum chamber is opened to the atmosphere, the fibers are taken out.

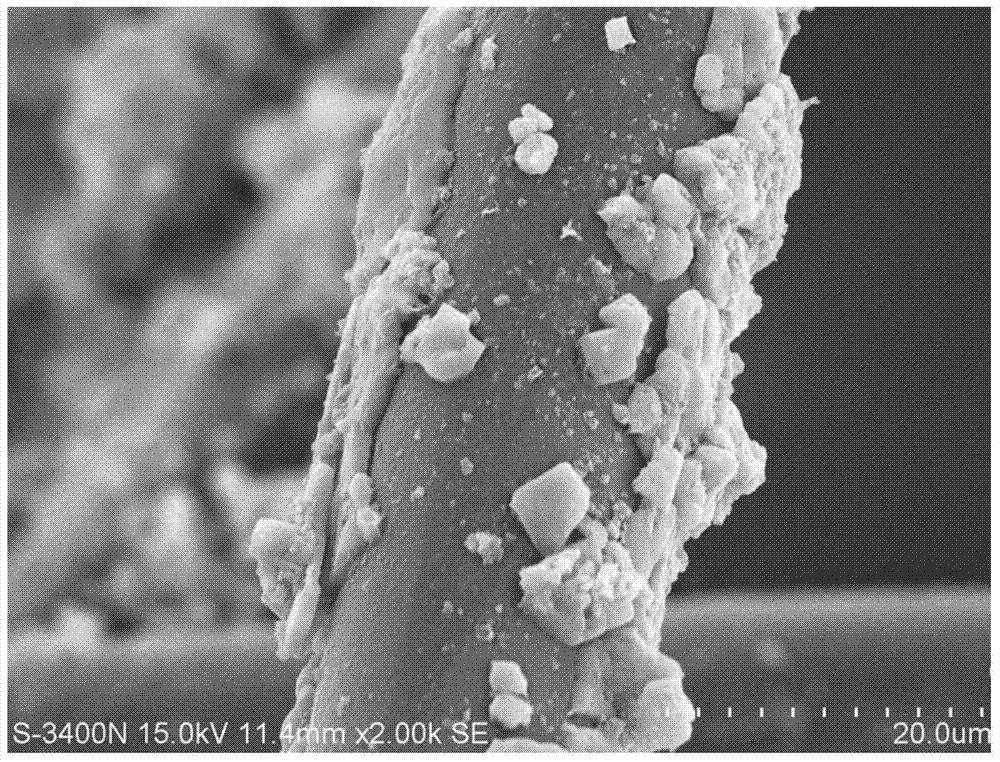

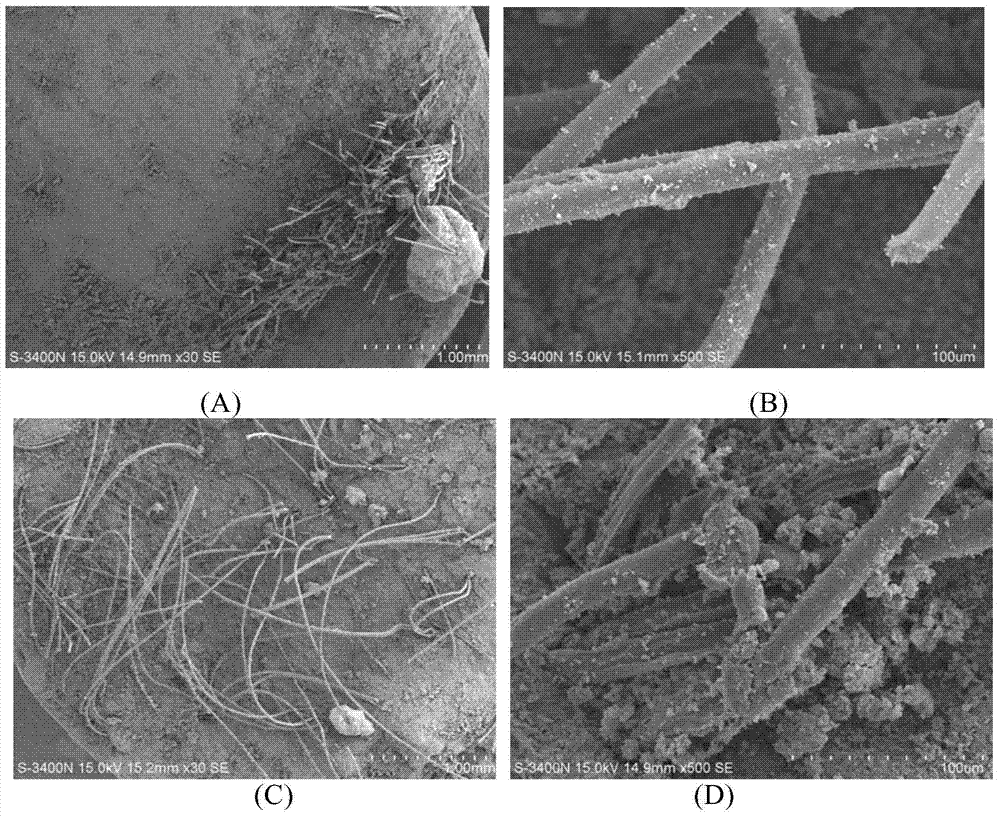

[0115] Weigh 60 mg of the PLGA fiber (polylactic acid-glycolic acid copolymer) after the above treatment, and the plasma treatment condition is O 2 Atmosphere, power 600w, time 120s) soaked in 0.2mg / mL dopamine solution (100mL), placed in 37℃, 100% humidity environment for 24h, took it out and dried it, cut it into 1mm length, and then scanned electron microscope test, such as figure 1 As shown, a large n...

Embodiment 2

[0118] Take by weighing the PLGA fiber after 100mg plasma treatment (processing method is similar to embodiment 1, and plasma treatment condition is 0 2 Atmosphere, power 300w, time 10s) Soak in 100mL of 0.2mg / mL dopamine solution, put in 37℃, 100% humidity environment for 24h, take it out and dry it, cut into 2mm sections.

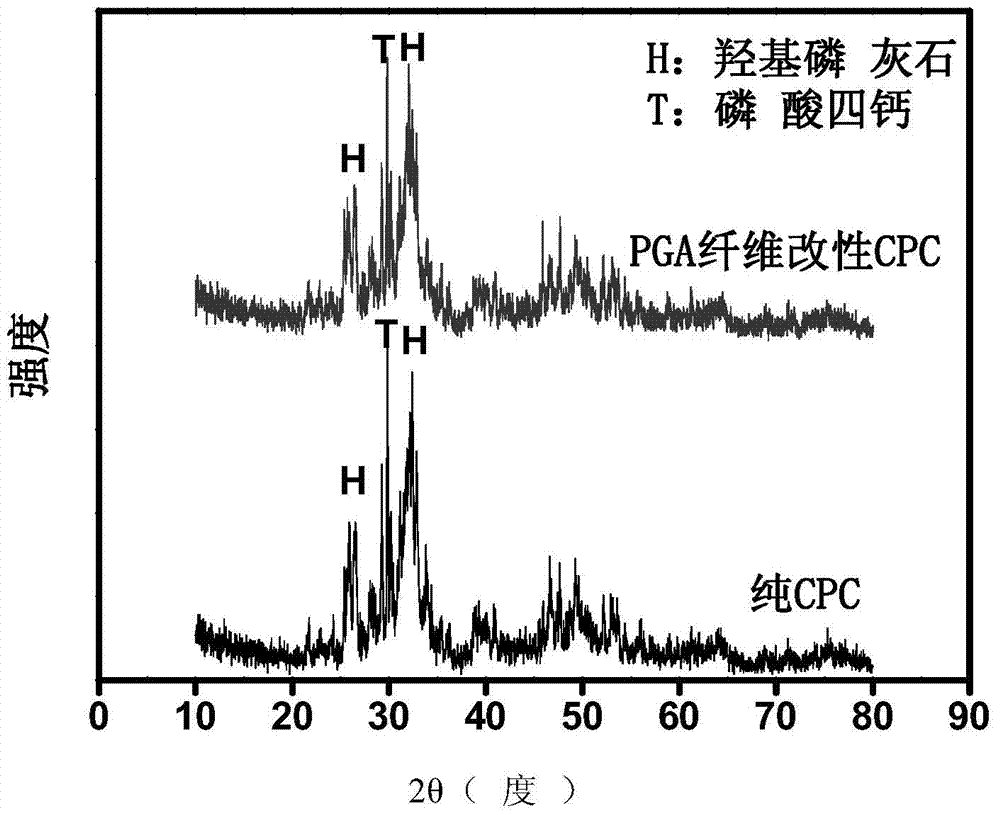

[0119] Weigh 1g of self-curing calcium phosphate bone cement powder composed of calcium hydrogen phosphate, tetracalcium phosphate and hydroxyapatite, add 5mg of treated fibers, mix well, add 0.3mL of 0.3% sodium hyaluronate solution, and quickly Prepare it evenly, then fill it into the mold, and place it in an environment of 37°C and 100% humidity for curing. The curing time of the composite bone cement is 8 minutes, and its compressive strength is 36MPa after drying after demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Curing time | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com