Coking wax oil complexing denitrification refining method

A technology for coking wax oil and refining method, which is applied in the direction of non-metal refining, etc., can solve the problems of high investment in hydrogen production equipment, high operating costs, and unsatisfactory denitrification effect of solvent refining, and achieves reliable material guarantee and good selectivity. , the effect of high denitrification reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of complexing modifier: 25% maleic anhydride, 50% 1-butyl-3-methylimidazolium tetrafluoroborate, 7% polyacrylamide, 2% bis-imidazoline quaternary ammonium salt, 16% glycerol.

[0029] Refining is carried out through the following steps: (1) Pre-mixing Lanzhou Petrochemical Coker Wax Oil (its properties are shown in Table 1) with a complex modifier, and the mass fraction of the complex modifier added is 1%;

[0030] (2) After fully stirring and mixing at 90~100°C for 30 minutes, let it stand at 90~100°C for heat preservation, and settle naturally by gravity for 4 hours. The complexed derivatives settle at the bottom of the settling tank, and the upper part gets refined oil. Its properties are listed in Table 1.

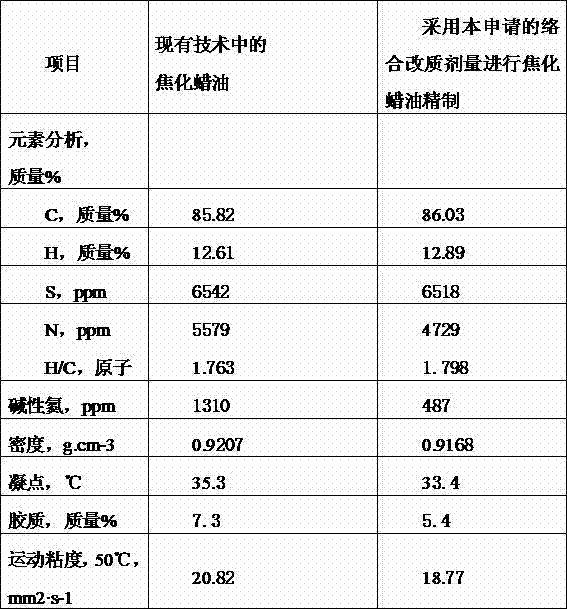

[0031] Table 1 Comparison of the properties of coker wax oil refined in the prior art and the complex modification dosage of the present application:

[0032]

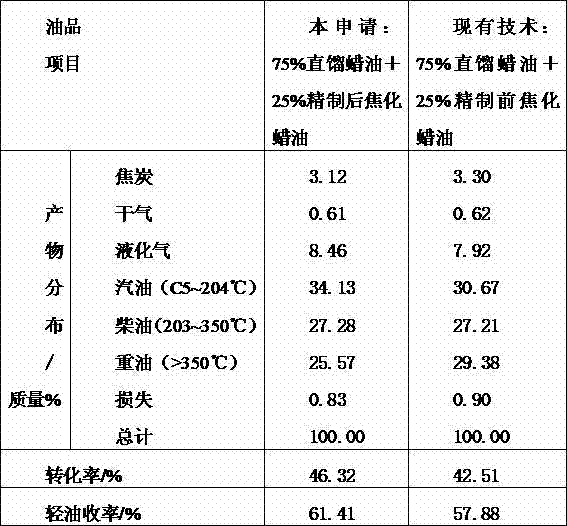

[0033] (3) During the refining process of coking wax oil in the prior art and the co...

Embodiment 2

[0039] Preparation of complexing modifier: 25% maleic anhydride, 50% 1-butyl-3-methylimidazolium tetrafluoroborate, 7% polyacrylamide, 2% bis-imidazoline quaternary ammonium salt, 16% glycerol.

[0040] Refining is carried out through the following steps: (1) Pre-mixing Wuhan Petrochemical Coker Wax Oil (its properties are shown in Table 3) with a complex modifier, and the mass fraction of the complex modifier added is 1.9%;

[0041] (2) After fully stirring and mixing at 90~100°C for 30 minutes, let it stand at 90~100°C for heat preservation, and settle naturally by gravity for 4 hours. The complexed derivatives settle at the bottom of the settling tank, and the upper part gets refined oil. Its properties are listed in Table 3.

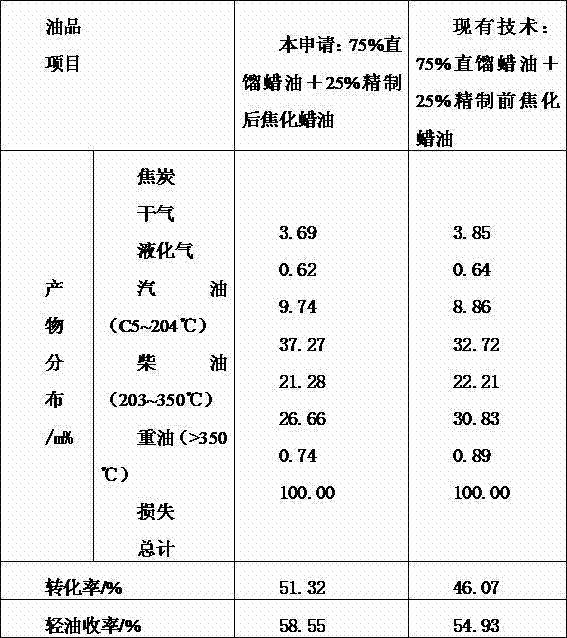

[0042] Table 3 Comparison of the properties of coker wax oil refined in the prior art and the complex modification dosage of the present application

[0043] project Before the refining of coker wax oil in the prior art Carry out refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com