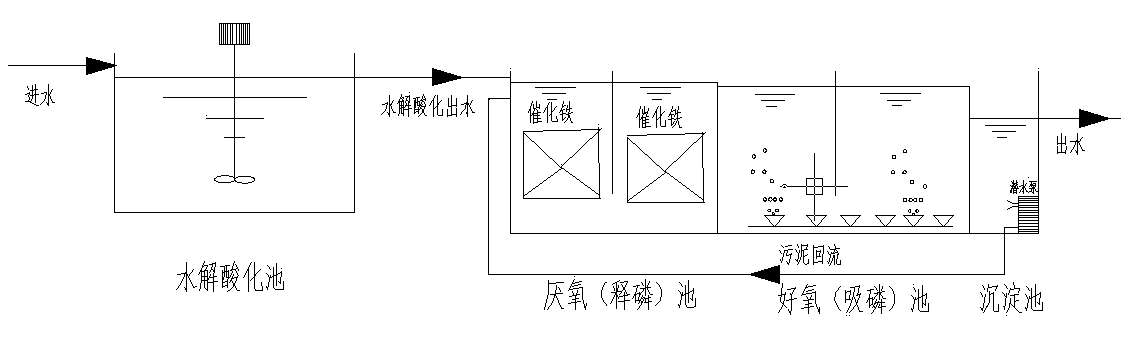

Hydrolytic acidification-catalyzed iron/anaerobic-aerobic biological dephosphorization coupling process

A hydrolytic acidification, aerobic biological technology, applied in anaerobic digestion treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve problems such as increased salinity, large drop in pH value, unfavorable nitrification reaction, etc. , to achieve the effect of improving stability and efficiency, high phosphorus content in sediment, and improving phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Phosphorus removal from urban sewage with low organic acid content

[0025] Due to the short urban pipe network and low temperature, hydrolysis and acidification cannot be carried out in the pipe network of sewage in a certain city, and the VFA (volatile organic acid) content of the influent is about 2 mmol / L. Influent BOD 5 The phosphorus content is 150 mg / L, the phosphorus content is 10 mg / L, and the pH value is 7.0. The original A / O biological phosphorus removal process parameters are: hydraulic retention time A section 3 hours, O section 6 hours, after treatment effluent: BOD 5 is 9 mg / L, and the phosphorus content is 3 mg / L.

[0026] Pre-hydrolysis acidification process, hydraulic retention time is 2 hours, upflow, fixed biological packing bed. Catalytic iron filler is placed in section A, with a bulk density of 100kg / M 3 .

[0027] The treatment effect of the new process: the organic acid content in the A section is increased to 10 mmol / L, the ORP (...

Embodiment 2

[0028] Example 2 Phosphorus removal from urban sewage with intermediate organic acid content

[0029] In the sewage of a certain city, the content of volatile organic acids in the influent is in the middle, and the VFA is about 8 mmol / L. Influent BOD 5 The phosphorus content is 150 mg / L, the phosphorus content is 6 mg / L, and the pH value is 7.0. The original A / O biological phosphorus removal process parameters are: hydraulic retention time A section 3 hours, O section 6 hours, after treatment effluent: BOD 5 is 9 mg / L, and the phosphorus content is 2 mg / L.

[0030] Pre-hydrolysis acidification process, hydraulic retention time is 2 hours, upflow, fixed biological packing bed. Catalytic iron filler is placed in section A, with a bulk density of 100kg / M 3 .

[0031] The treatment effect of the new process: the content of organic acid in section A is increased to 12 mmol / L, the ORP (oxidation-reduction potential) is reduced from +50 mV without catalytic iron to -80 mV after ...

Embodiment 3

[0032] Example 3 Phosphorus removal from urban sewage with high organic acid content

[0033] Due to the long urban pipe network and high temperature, hydrolytic acidification has been carried out in the sewage pipe network in a certain city, and the VFA (volatile organic acid) content of the influent is about 15 mmol / L. Influent BOD 5 The phosphorus content is 150 mg / L, the phosphorus content is 10 mg / L, and the pH value is 6.9. The original A / O biological phosphorus removal process parameters are: hydraulic retention time A section 3 hours, O section 6 hours, after treatment effluent: BOD 5 is 8 mg / L, and the phosphorus content is 1.5 mg / L.

[0034] Pre-hydrolysis acidification process, hydraulic retention time is 2 hours, upflow, fixed biological packing bed. Catalytic iron filler is placed in section A, with a bulk density of 100kg / M 3 .

[0035] The treatment effect of the new process: the content of organic acid in section A is increased to 15 mmol / L, the ORP (oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com