Porous film for secondary battery, production method and use

A secondary battery and porous membrane technology, applied in secondary batteries, battery electrodes, battery components, etc., can solve the problems of bad influence on battery performance and difficulty in reducing content, and achieve uniform film thickness distribution and strength distribution, long service life Long-lasting, avoid powder falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

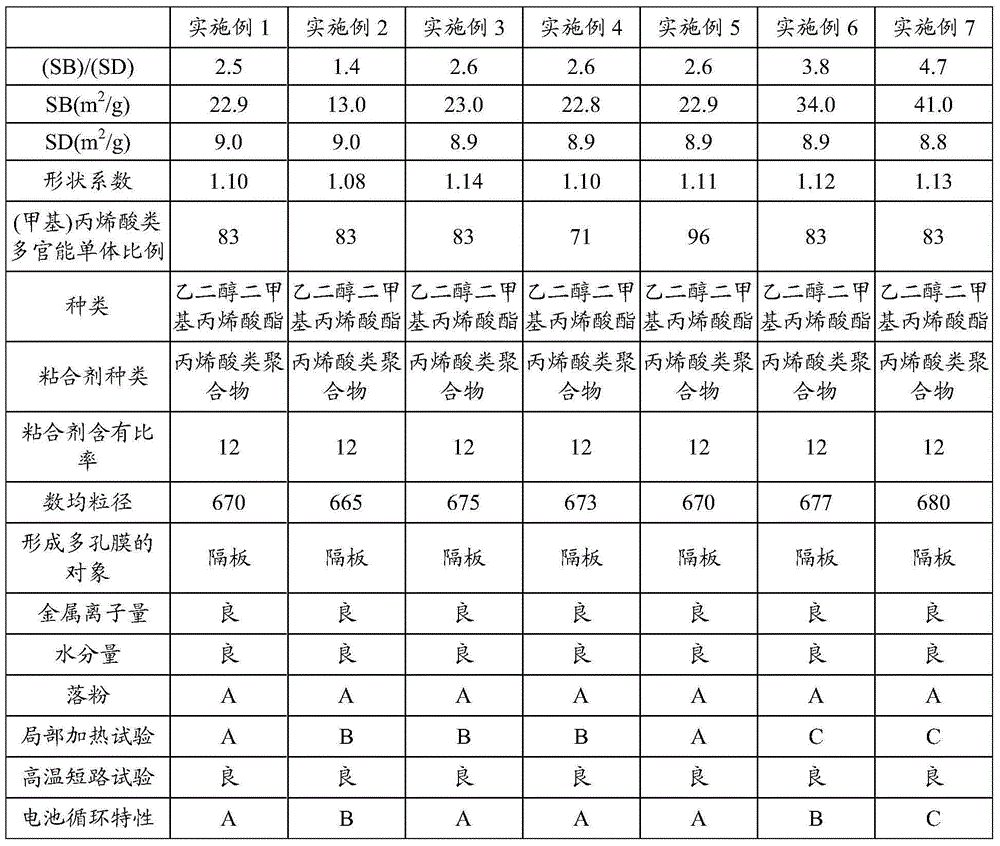

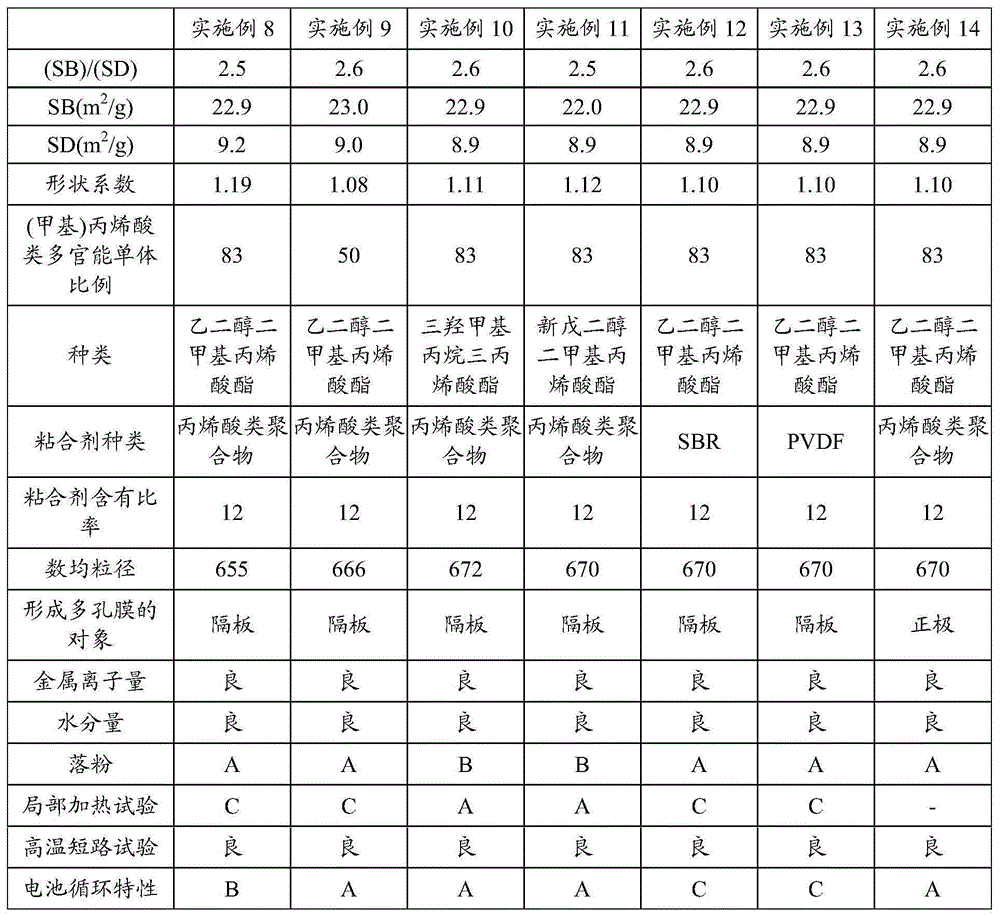

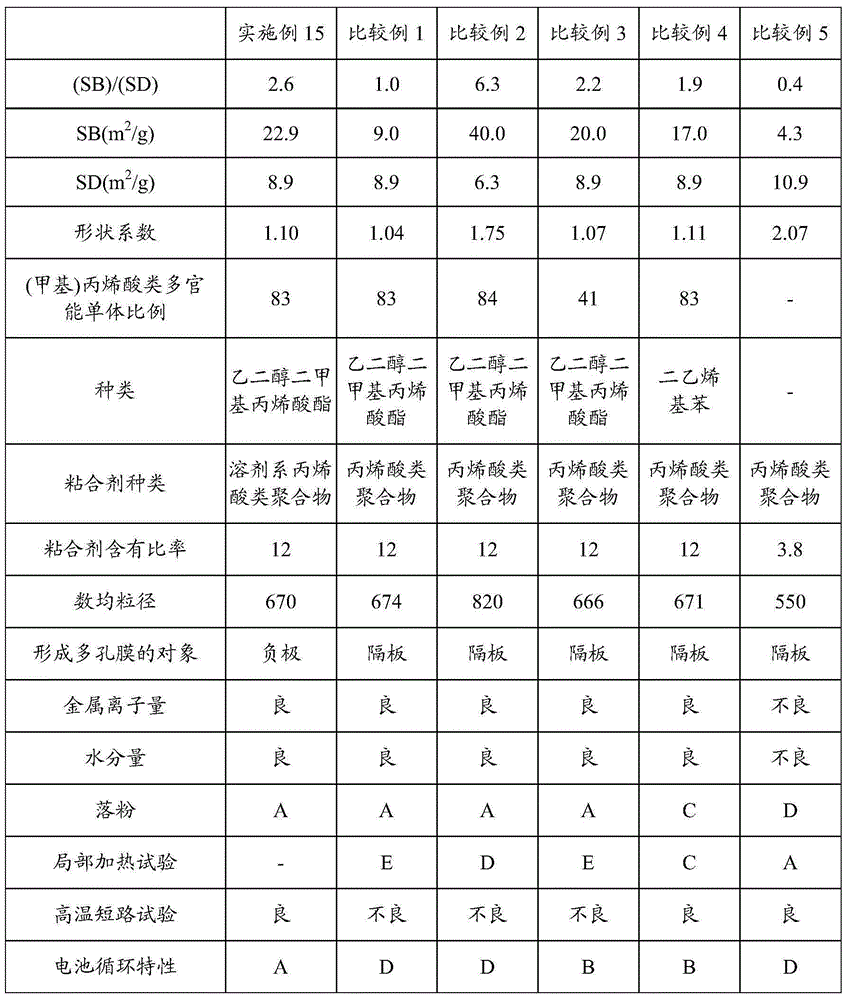

Examples

Embodiment 1

[0330] (1-1. Production of seed polymer particles A)

[0331] In a reactor equipped with a stirrer, 0.06 parts of sodium lauryl sulfate, 0.23 parts of ammonium persulfate, and 100 parts of ion-exchanged water were put and mixed to prepare mixture A, and the temperature was raised to 80°C.

[0332] On the other hand, 93.8 parts of butyl acrylate, 2.0 parts of methacrylic acid, 2.0 parts of acrylonitrile, 1.0 parts of allyl glycidyl ether, 1.2 parts of N-methylol acrylamide, and dodecyl were mixed in another container. 0.1 part of sodium sulfate and 100 parts of ion-exchanged water were used to prepare a dispersion of the monomer mixture 1 .

[0333] This dispersion of the monomer mixture 1 was continuously added to the above obtained mixture A over 4 hours and allowed to polymerize. The temperature of the reaction system during the continuous addition of the dispersion of the monomer mixture 1 was maintained at 80°C, and the reaction was carried out. After the continuous addi...

Embodiment 2

[0359] (2-1. Production of seed polymer particles B)

[0360] In a reactor equipped with a stirrer, 0.06 parts of sodium lauryl sulfate, 0.23 parts of ammonium persulfate, and 100 parts of ion-exchanged water were put and mixed to prepare mixture B, and the temperature was raised to 80°C.

[0361] On the other hand, 93.8 parts of butyl acrylate, 2.0 parts of methacrylic acid, 2.0 parts of acrylonitrile, 1.0 parts of allyl glycidyl ether, 1.2 parts of N-methylol acrylamide, and dodecyl were mixed in another container. 0.1 part of sodium sulfate, 2.0 parts of t-dodecyl mercaptan, and 100 parts of ion-exchanged water were used to prepare a dispersion of monomer mixture 2.

[0362] The dispersion of the monomer mixture 2 was continuously added to the mixture B obtained above to polymerize over 4 hours. The temperature of the reaction system was maintained at 80° C. during the continuous addition of the dispersion of the monomer mixture 2, and the reaction was carried out. After ...

Embodiment 3

[0369] (3-1. Production of non-conductive particles C)

[0370] In a reactor equipped with a stirrer, 20 parts of the water dispersion of the seed polymer particles A obtained in the step (1-1) of Example 1 was placed on the basis of the solid content (that is, the weight basis of the seed polymer particles A). , 100 parts of ethylene glycol dimethacrylate (Kyoeisha Chemical Co., Ltd., product name: Light EsterEG) as a monomer, 1.0 parts of sodium dodecylbenzenesulfonate, and tert-butyl permethacrylate as a polymerization initiator 4.0 parts of oxy-2-ethylhexanoate (manufactured by NOF Corporation, trade name: PERBUTYL O), 50 parts of cyclohexanol, and 200 parts of ion-exchanged water were stirred at 35° C. for 12 hours to polymerize seeds The polymer particles A completely absorb the monomers and polymerization initiators. Then, it was polymerized at 90 degreeC for 5 hours. Then, steam is introduced to remove the non-reactive solvent, unreacted monomers and initiator decomp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com