Thermal treatment method for inhibiting and eliminating banded structure in low-alloy and heatproof steel tube

A heat treatment method and banded structure technology, which is applied in heat treatment equipment, manufacturing tools, quenching agents, etc., can solve problems such as molding and other process difficulties, achieve versatility and effectiveness, broad application prospects, and eliminate banded structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

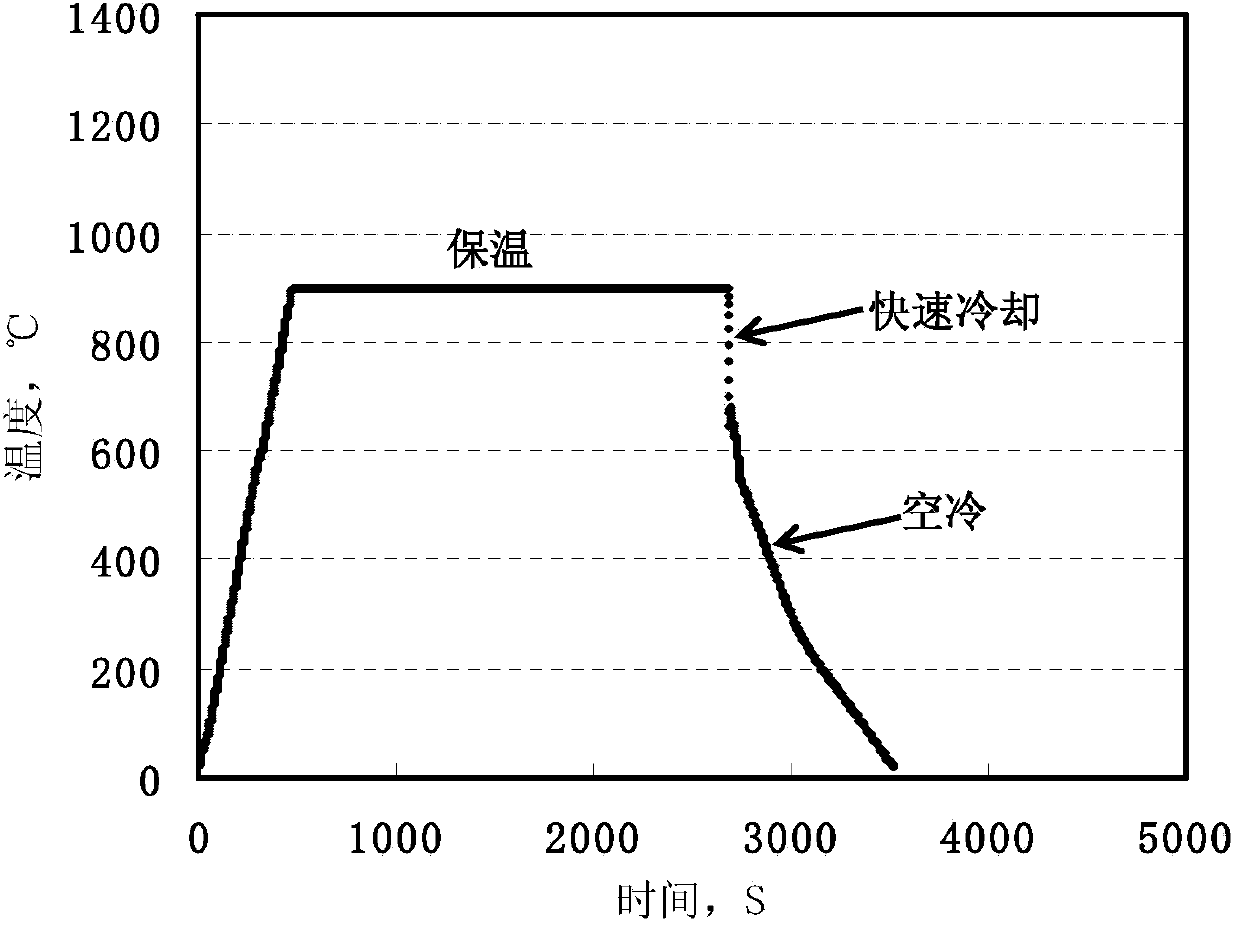

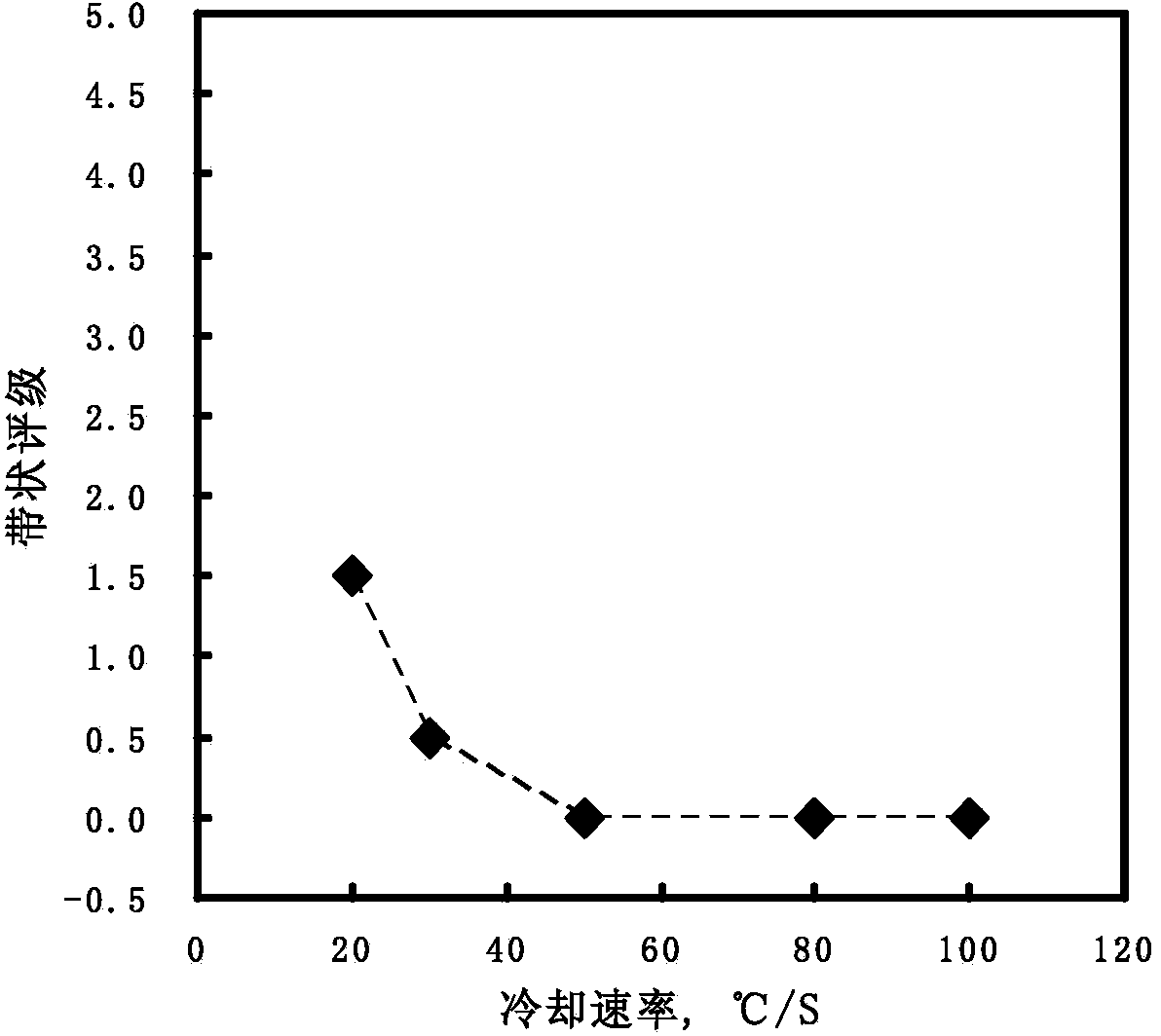

[0033] Cut a certain length of SA-210Gr.C pipe, the pipe size (outer diameter × wall thickness) is 57 × 7mm, grade the banded structure of the rolled pipe as 4.5, and then machine it into a cylindrical sample. The sample was heated to 880°C at a heating rate of 30°C / min by a thermal expansion tester, and kept warm for 8 minutes. Then rapid cooling to 620°C was performed by spraying high-velocity nitrogen gas to the sample at 20°C / S, and then the sample was air-cooled to room temperature.

[0034] The sample treated above was sawed along the axial direction, then inlaid with resin, ground, polished and chemically etched. The metallographic structure was observed under an optical microscope, and the banded structure was graded according to the national standard GB / T13299-91. The rating result is 1.5, such as Figure 5a As shown, it can be seen that the banding is significantly reduced. Microhardness testing was carried out on the sample, and the Vickers hardness value was 172,...

Embodiment 2

[0036] Cut a certain length of SA-210Gr.C pipe, the pipe size (outer diameter × wall thickness) is 51 × 7mm, grade the banded structure of the rolled pipe as 4.5, and then machine it into a cylindrical sample. The sample was heated to 890°C at a heating rate of 40°C / min by a thermal expansion tester, and kept warm for 8 minutes. Then rapid cooling was performed to 630°C by spraying high-velocity nitrogen gas to the sample at 50°C / S, and then the sample was air-cooled to room temperature.

[0037] The sample treated above was sawed along the axial direction, then inlaid with resin, ground, polished and chemically etched. The metallographic structure was observed under an optical microscope, and the banded structure was graded according to the national standard GB / T13299-91. The rating result is level 0, such as Figure 5b As shown, it can be seen that the banding is completely eliminated. Microhardness testing was carried out on the sample, and the measured hardness value was...

Embodiment 3

[0039] Cut a certain length of SA-210Gr.C pipe, the pipe size (outer diameter × wall thickness) is 57 × 4mm, grade the banded structure of the as-rolled pipe to grade 5, and then machine it into a cylindrical sample. The sample is heated to 910°C by a thermal expansion tester at a heating rate of 50°C / min, and kept warm for 8 minutes. Then rapid cooling to 600 °C was performed by spraying high-velocity nitrogen gas to the sample at 100 °C / S, and then the sample was air-cooled to room temperature.

[0040] The sample treated above was sawed along the axial direction, then inlaid with resin, ground, polished and chemically etched. The metallographic structure was observed under an optical microscope, and the band structure was graded according to the national standard GB / T13299-91. The rating result is level 0, such as Figure 5c As shown, it can be seen that no band-like structure was formed in the sample. Microhardness testing was carried out on the sample, and the measured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com