Method for co-producing plurality of saccharic acids from cellulose fuel ethanol

A technology for fuel ethanol and cellulose, which is applied in the directions of microorganism-based methods, biofuels, biochemical equipment and methods, etc., can solve the problems of poor tolerance of inhibitors, affecting commercial production, and high production costs, and achieves a high base The effect of improving the overall utilization rate and eliminating waste water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

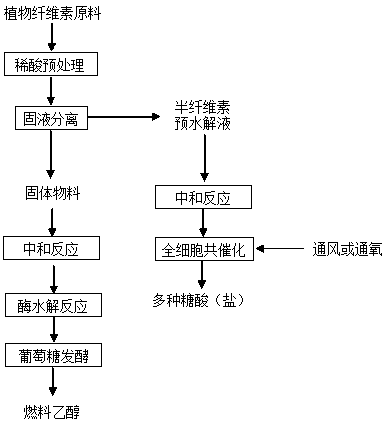

[0020] Process flow for the co-production of various sugar acids from cellulosic fuel ethanol, such as figure 1 shown. The specific process is as follows:

[0021] Cut 1000g (dry basis) of corn stalks mechanically to 3-10cm, put them into a 15L stainless steel cooking kettle, add 0.25-2.0% sulfuric acid, and fully impregnate them with a solid-liquid ratio (1:5, w / v). Use an electric jacket to heat to 150~160°C, and react for 40~60 minutes to get the pretreated material. The pretreated material is extruded by a spiral filter to obtain a pretreated liquid, and the remaining solid material is made into a slurry solid material through a refining process.

[0022] Transfer the slurry-like solid material to a 100L mechanically stirred reactor, and add hot water to adjust the slurry-like solid material to 10% (mass concentration). Turn on the mechanical stirrer to 300r / min, add 35% NaOH to neutralize to pH 4.8. Add the enzyme preparation according to the standard of 9 FPIU cellu...

Embodiment 2

[0027] Process flow for the co-production of various sugar acids from cellulosic fuel ethanol, such as figure 1 shown. The specific process is as follows:

[0028] 1000g (dry basis) corn stalk raw material was mechanically cut to 3-10cm, transferred to a 15L stainless steel cooking kettle, added 2.0% hydrochloric acid, and fully impregnated with a solid-to-liquid ratio (1:10, w / v). Use an electric jacket to heat to 160~170°C, and react for 20~40min to get the pretreated material. The pretreated material is extruded by a spiral filter to obtain a pretreated liquid, and the remaining solid material is made into a slurry solid material through a refining process.

[0029] Transfer the slurry-like solid material to a 100L mechanically stirred reactor, and add hot water to adjust the slurry-like solid material to 10% (mass concentration). Turn on the mechanical stirrer to 300r / min, add 30% NaOH to neutralize to pH 4.8. Add enzyme preparations according to the standard of 10 FP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com