On-site verification apparatus for optical fiber current sensor

A fiber optic current, field calibration technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve long-term stability, reliability and safety and other indicators difficult to meet industry requirements, measurement accuracy is difficult to reach 0.05%, current Detecting problems such as out-of-tolerance sensor accuracy, to achieve the effects of convenient and safe installation, improved detection sensitivity, and reduced transmission errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An on-site verification device for an optical fiber current sensor, comprising a connected optical fiber current detection sensing module and an optical fiber current detection processing and display module 9, wherein the optical fiber current detection sensing module modulates a reference light and then compares it with the detected signal Closed-loop control mode in which comparison processing is performed to obtain verification results.

Embodiment 2

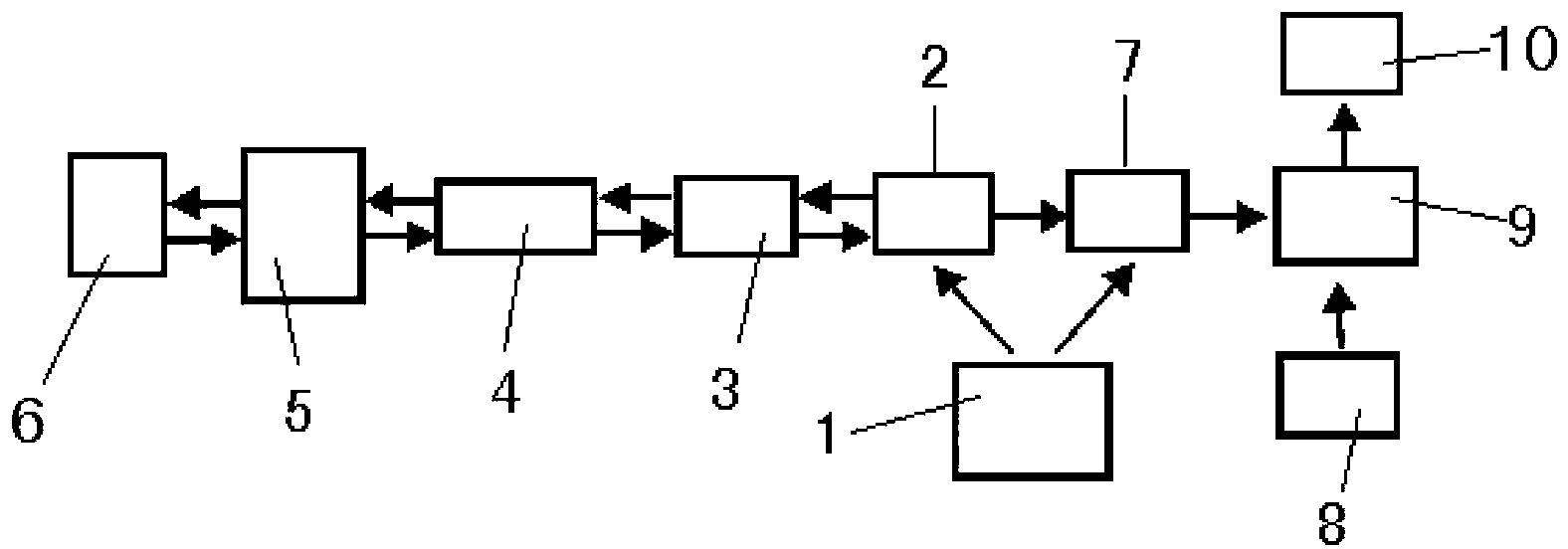

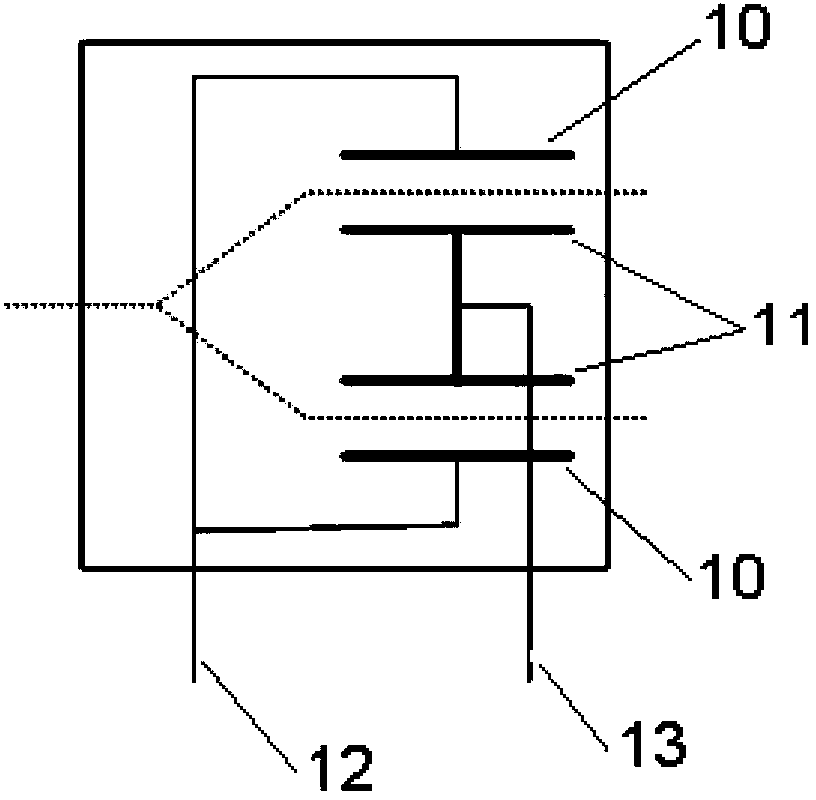

[0045] Such as figure 1As shown, an on-site verification device for a fiber optic current sensor is the same as in Embodiment 1, except that the fiber optic current detection sensing module consists of a light source 1, a linear polarizer, a polarization separator, a modulator 2, and a transmission fiber 3 , 1 / 4 wavelength filter 4, optical fiber sensing head 5, mirror 6 and photodetector 7; the optical fiber sensing head 5 and the sensor 8 to be verified are surrounded on the same conductive bus; the light source 1 The modulator 2 is connected to the modulator 2 through a linear polarizer and a polarization splitter, and the modulator 2 is connected to the transmission fiber 3, and the transmission fiber 3 is connected to the 1 / 4 wavelength filter 4, and the 1 / 4 The wavelength filter 4 is connected with the optical fiber sensing head 5 again, and the optical fiber sensing head 5 is connected with the radiation mirror; the light source 1 is also connected with the photodetecto...

Embodiment 3

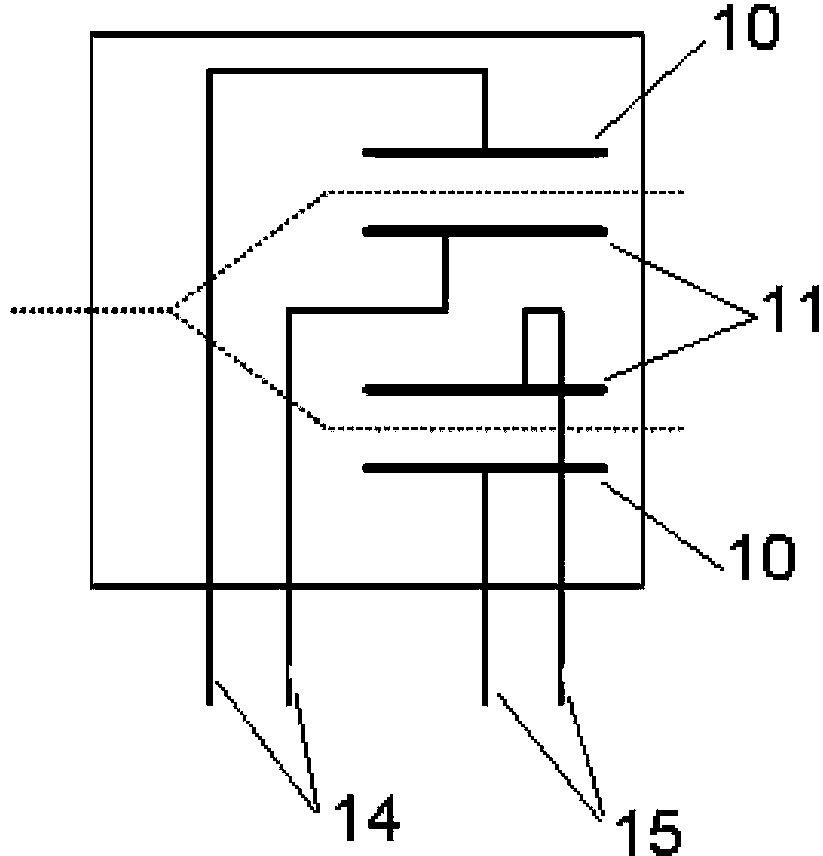

[0047] Such as figure 1 and image 3 As shown, an on-site verification device for an optical fiber current sensor is the same as that in Embodiment 2, except that the modulation signal of the modulator 2 is separated from the closed-loop signal and applied to the two arms of the modulator 2 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com