Germanium nanotube top raised array modified by silver nano-particles as well as preparation method and application thereof

A technology of silver nanoparticles and nanotubes, applied in the field of nanotube arrays and preparation, can solve the problems of environmental pollution, disordered arrangement of germanium nanowires, poor SERS signal repeatability, etc., and achieves good consistency and repeatability and signal repeatability. Good, scientific effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

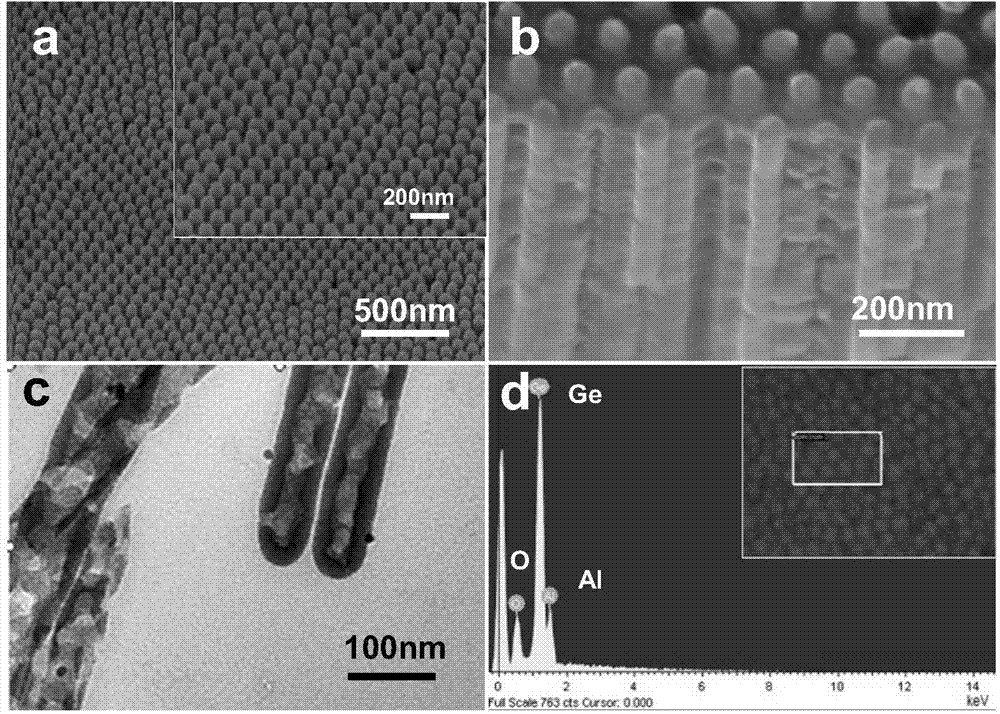

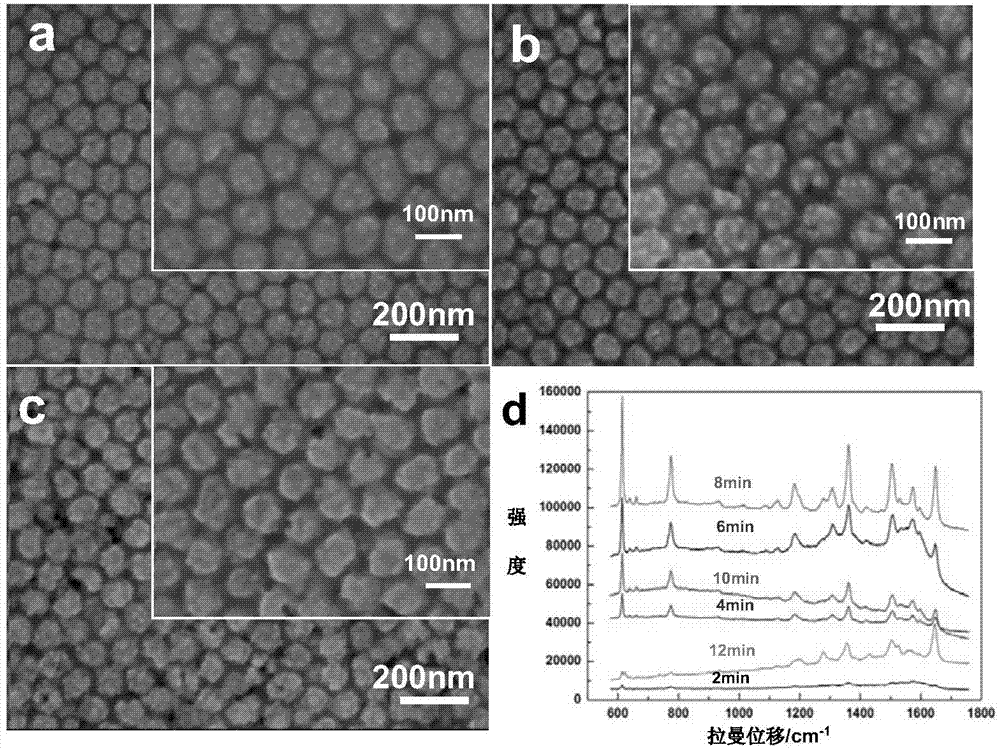

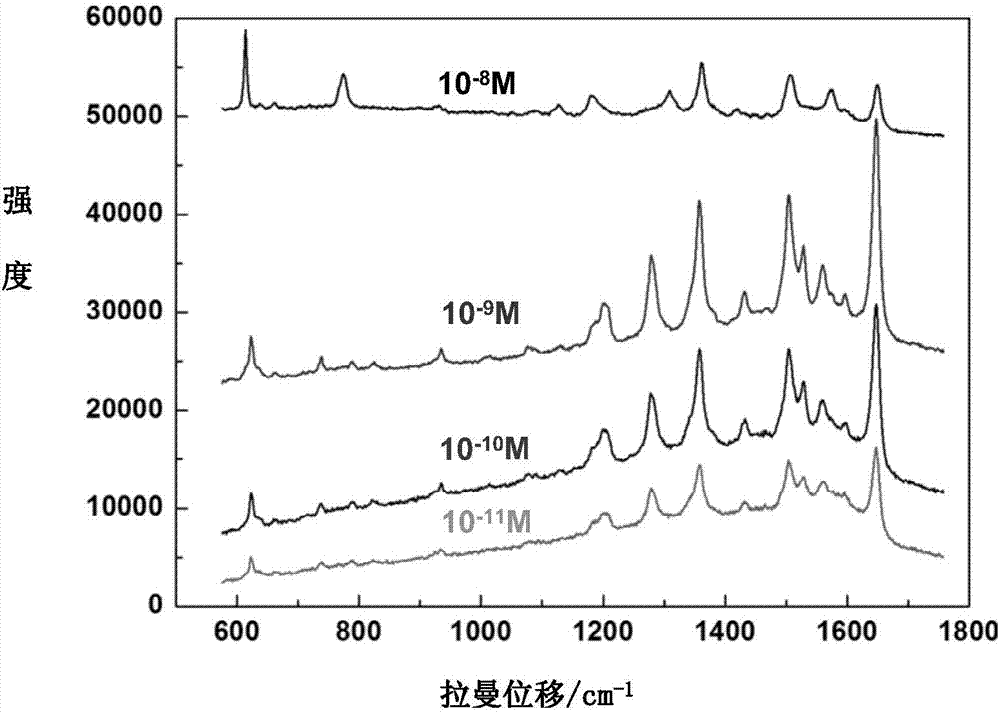

[0037] The concrete steps of preparation are:

[0038] Step 1, first soak the blind-hole alumina template in a mixed aqueous solution of nickel nitrate and phosphoric acid at a temperature of 35°C for 28 minutes; wherein, the weight ratio of nickel nitrate, phosphoric acid and water is 27:12:200. After taking it out, it was soaked and rinsed with a nickel nitrate aqueous solution with a concentration of 0.4 mol / L to obtain a blind hole alumina template with nickel nitrate adsorbed on the hole wall.

[0039] Step 2, after placing the blind hole aluminum oxide template with nickel nitrate adsorbed on the hole wall in the chemical vapor deposition furnace cavity, vacuumize the chemical vapor deposition furnace cavity and gas path in sequence and use argon to clean it. Subsequently, the furnace chamber was placed under an argon atmosphere, and the temperature was raised from room temperature to 280° C. at a rate of 10° C. / min. Then keep the furnace cavity with a deposition atmosp...

Embodiment 2

[0042] The concrete steps of preparation are:

[0043] Step 1, first soak the blind-hole alumina template in a mixed aqueous solution of nickel nitrate and phosphoric acid at a temperature of 38°C for 26 minutes; wherein, the weight ratio of nickel nitrate, phosphoric acid and water is 28:11:200. After taking it out, it is soaked and rinsed with a nickel nitrate aqueous solution with a concentration of 0.45 mol / L to obtain a blind hole alumina template with nickel nitrate adsorbed on the hole wall.

[0044] Step 2, after placing the blind hole aluminum oxide template with nickel nitrate adsorbed on the hole wall in the chemical vapor deposition furnace cavity, vacuumize the chemical vapor deposition furnace cavity and gas path in sequence and use argon to clean it. Subsequently, the furnace chamber was placed under an argon atmosphere, and the temperature was raised from room temperature to 290° C. at a rate of 10° C. / min. Then keep the furnace cavity with a deposition atmosp...

Embodiment 3

[0047] The concrete steps of preparation are:

[0048] Step 1, first soak the blind-hole alumina template in a mixed aqueous solution of nickel nitrate and phosphoric acid at a temperature of 40°C for 24 minutes; wherein, the weight ratio of nickel nitrate, phosphoric acid and water is 29:10:200. After taking it out, soak and rinse it with a nickel nitrate aqueous solution with a concentration of 0.5 mol / L to obtain a blind hole alumina template with nickel nitrate adsorbed on the hole wall.

[0049] Step 2, after placing the blind hole aluminum oxide template with nickel nitrate adsorbed on the hole wall in the chemical vapor deposition furnace cavity, vacuumize the chemical vapor deposition furnace cavity and gas path in sequence and use argon to clean it. Subsequently, the furnace chamber was placed under an argon atmosphere, and the temperature was raised from room temperature to 300° C. at a rate of 10° C. / min. Then keep the furnace cavity with a deposition atmosphere wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com