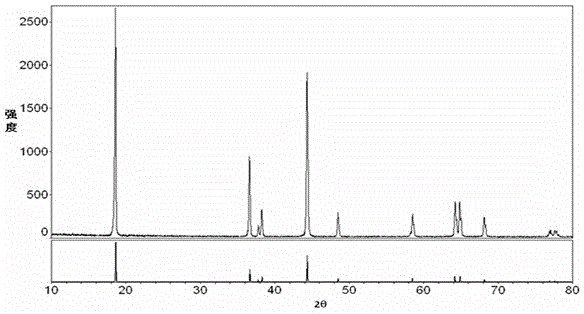

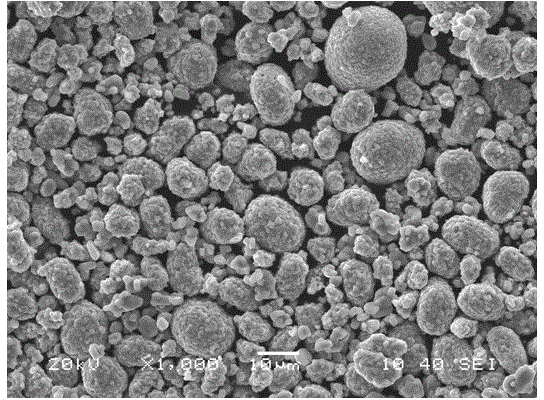

A high-capacity power nickel-rich lithium-ion battery cathode material and preparation method thereof

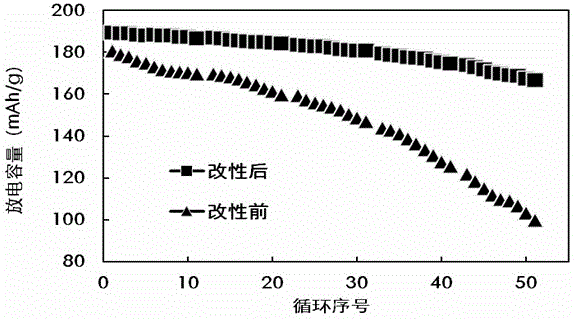

An ion battery and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of affecting the electrical properties of materials, decrease in efficiency, and high capacity, and achieve improved efficiency and rate, improved structural stability, and stable material structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the high-capacity power type nickel-rich lithium-ion battery positive electrode material of the present embodiment comprises the following steps:

[0039] (1) Weigh 3000g nickel-rich multi-component material precursor (molecular formula is Ni 0.6 co 0.2 mn 0.2 (OH) 2 ), 1311g of lithium carbonate, 10.5g of zirconia, and 31.2g of magnesia were put into a ball mill and mixed for 240 minutes. The mixed raw materials were put into a muffle furnace and sintered at 890°C for 12 hours in an air atmosphere to obtain rich Nickel multi-component material (molecular formula Li(Ni 0.6 co 0.2 mn 0.2 ) 0.977 Zr 0.003 Mg 0.02 o 2 );

[0040] (2) Weigh 10.2 g of aluminum nitrate and dissolve it in deionized water to prepare a 2.5 mol / L solution, add dropwise sodium hydroxide solution to adjust the pH value of the solution to 5.5, and obtain aluminum coating solution A;

[0041] (3) Weigh 20.8 g of cobalt nitrate and dissolve it in deionized water t...

Embodiment 2

[0047] The preparation method of the high-capacity power type nickel-rich lithium-ion battery positive electrode material of the present embodiment comprises the following steps:

[0048] (1) Weigh 3000g nickel-rich multi-component material precursor (molecular formula is Ni 0.7 co 0.2 Al 0.1 (OH) 2 ), 1273g lithium hydroxide, 20.1g titanium dioxide (TiO 2 ), 10.8g zirconia (ZrO 2 ), 33.8g of magnesium oxide were put into a ball mill and mixed for 200 minutes, the mixed raw materials were put into a bell furnace, and sintered at 875°C for 14 hours in an oxygen atmosphere to obtain a nickel-rich multi-component material;

[0049] (2) Weigh 12.1g of aluminum phosphate and dissolve it in deionized water to prepare a 2mol / L solution, and adjust the pH value of the solution to 8 by adding sodium hydroxide and ammonia solution dropwise to obtain aluminum coating solution A;

[0050] (3) Weigh 100.5 g of cobalt sulfate and dissolve it in deionized water to prepare a 5 mol / L sol...

Embodiment 3

[0054] The preparation method of the high-capacity power type nickel-rich lithium-ion battery positive electrode material of the present embodiment comprises the following steps:

[0055] (1) Weigh 3000g nickel-rich multi-component material precursor (molecular formula is Ni 0.75 co 0.1 mn 0.1 Al 0.05 (OH) 2 ), 1301g of lithium hydroxide, 22.9g of alumina, and 50.3g of yttrium oxide were put into a ball mill and mixed for 200 minutes. The mixed raw materials were put into a bell furnace and sintered at 915°C for 10 hours in an oxygen atmosphere to obtain nickel-rich multiple materials;

[0056] (2) Weigh 12.1 g of aluminum nitrate and dissolve it in deionized water to prepare a 2 mol / L solution, add dropwise sodium hydroxide solution to adjust the pH value of the solution to 8.5, and obtain aluminum coating solution A;

[0057] (3) Weigh 100.5 g of cobalt acetate and dissolve it in deionized water to prepare a 5 mol / L solution, and adjust the pH value of the solution to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com