A rotary semi-shielded thermal shock sintering resistance furnace

A semi-shielding and thermal shock technology, applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problem of one-sided or uneven heating body, and achieve the effect of compact structure, low porosity and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

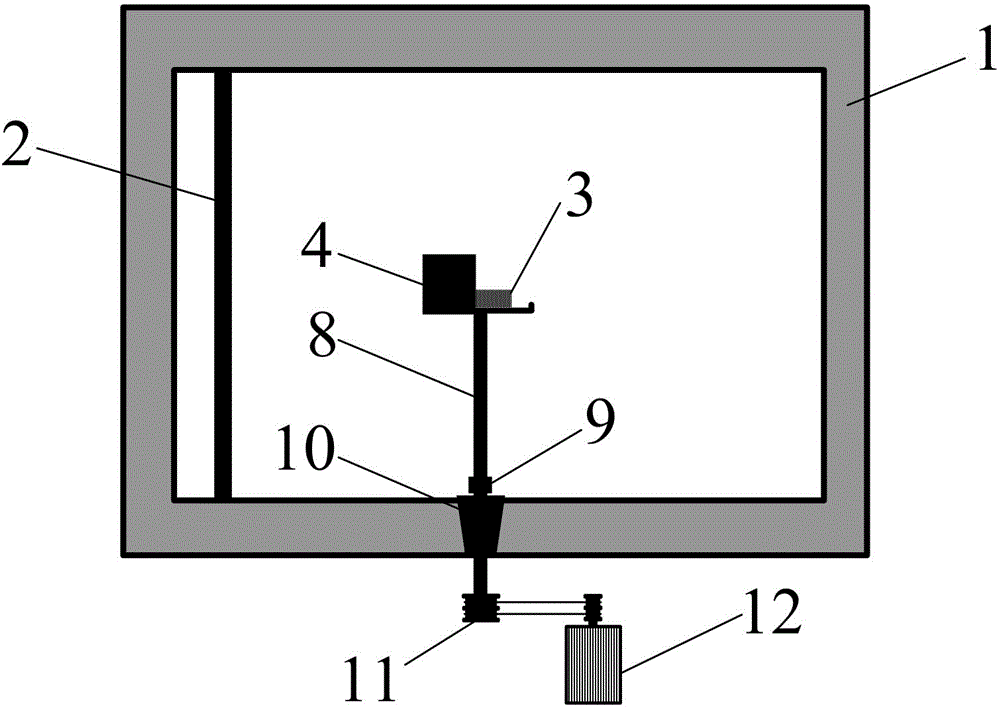

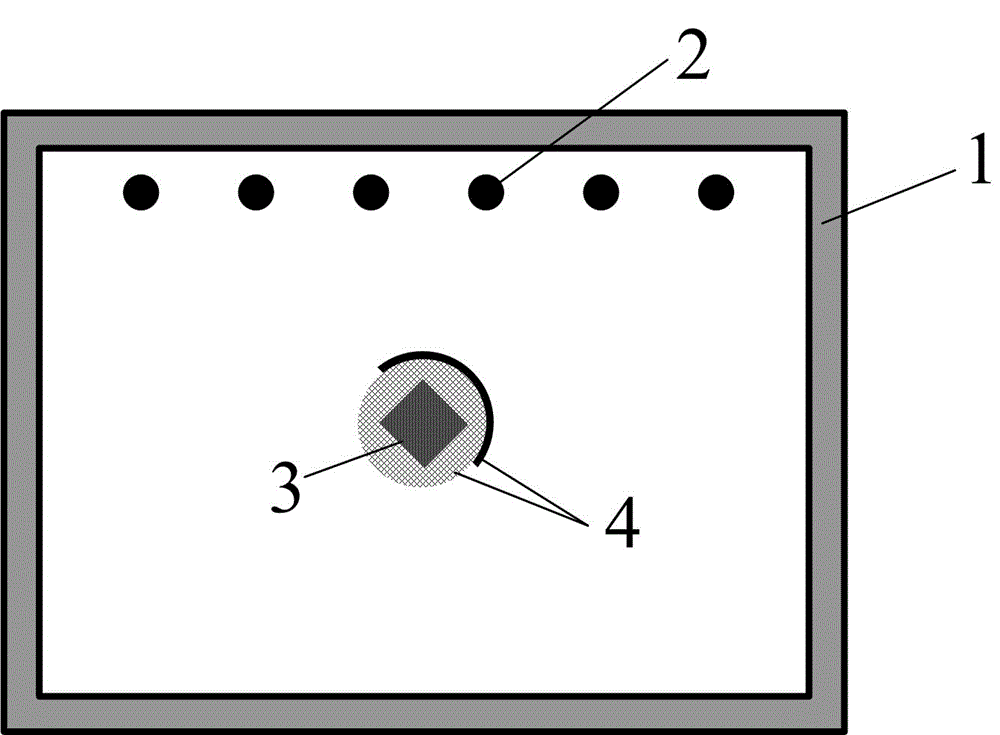

[0023] Embodiment 1: as figure 1 Schematic diagram of the front view of the vertical bottom installation of the rotary semi-shielded thermal shock sintering resistance furnace and figure 2 As shown in the top view schematic diagram of the vertical bottom installation of the rotary semi-shielding thermal shock sintering resistance furnace, the mechanical rotating shielding part of the rotary semi-shielding thermal shock sintering resistance furnace provided by the present invention is an integrated form of a semi-shielding loading crucible and a rotating support rod. There is a small hole at the bottom of the furnace shell 1, and the fixing frame 10 made of aluminum oxide passes through the furnace shell 1 through the small hole. The outer diameter of the upper part of the fixing frame 10 is slightly larger than the outer diameter of the lower part, and it is tightly stuck in the small hole of the furnace shell 1 , the material of the integrated semi-shielding crucible 4, the ...

Embodiment 2

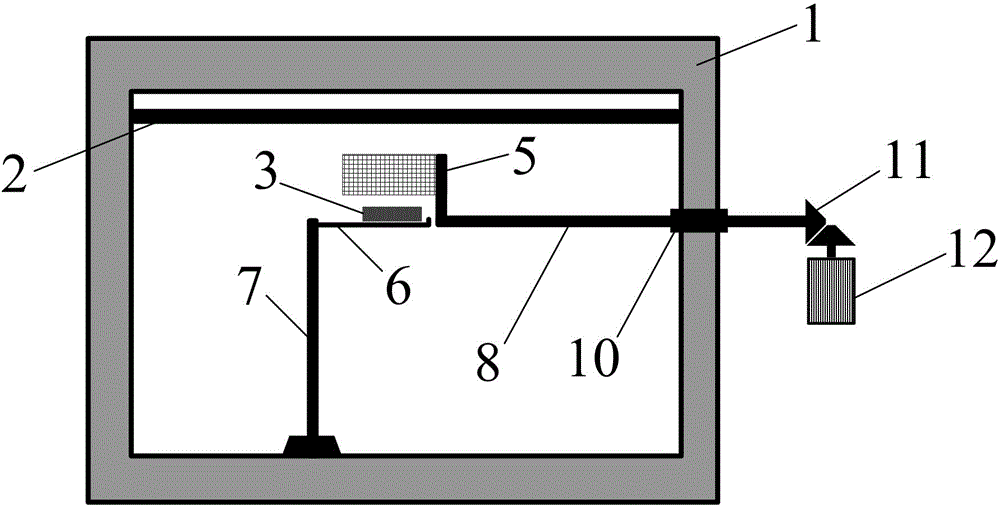

[0024] Embodiment 2: as image 3 Schematic diagram of the front view of the rotary semi-shielded thermal shock sintering resistance furnace with horizontal side installation and Figure 4As shown in the schematic diagram of the horizontal side-mounted top view, the mechanical rotating shielding part of the rotary semi-shielding thermal shock sintering resistance furnace provided by the present invention is in the form of a semi-shielding loading crucible and a separate rotating support rod. There are small holes on the side of the furnace shell 1. The fixed frame 10 made of high-temperature alloy steel passes through the furnace shell 1 through the small hole on the side of the furnace shell 1, and the fixed frame 10 is tightly stuck in the small hole of the furnace shell 1. The material is high temperature alloy steel, the material of the integrated loading crucible 6 and the crucible support frame 7 is high temperature alloy steel, the rotating support rod 8 is fixed by the ...

Embodiment 3

[0025] Embodiment 3: as Figure 5 As shown in the schematic diagram of the vertical top-mounted front view of the rotary semi-shielding thermal shock sintering resistance furnace, the mechanical rotating shielding part of the rotary semi-shielding thermal shock sintering resistance furnace provided by the present invention is in the form of a semi-shielding loading crucible and a rotating support rod. There is a small hole on the top of the furnace shell 1, and the fixing frame 10 made of alumina passes through the furnace shell 1 through the small hole. The materials of the arc-shaped semi-shielding plate 5 and the rotating support rod 8 are high-purity graphite, and the materials of the integrated loading crucible 6 and the crucible support frame 7 are high-purity graphite, and the rotating support rod 8 is fixed by a fixed frame 10, and rotates The outer wall of the support rod 8 and the inwall of the fixed mount 10 are smooth, and the outer diameter of the rotating support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com