Dual-modified lithium manganate material and preparation method thereof

A kind of permanent lithium manganate, lithium manganate technology, applied in the field of double modified lithium manganate material and its preparation, can solve problems such as uneven distribution, achieve full utilization, high capacity and cycle stability, and improve interface stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

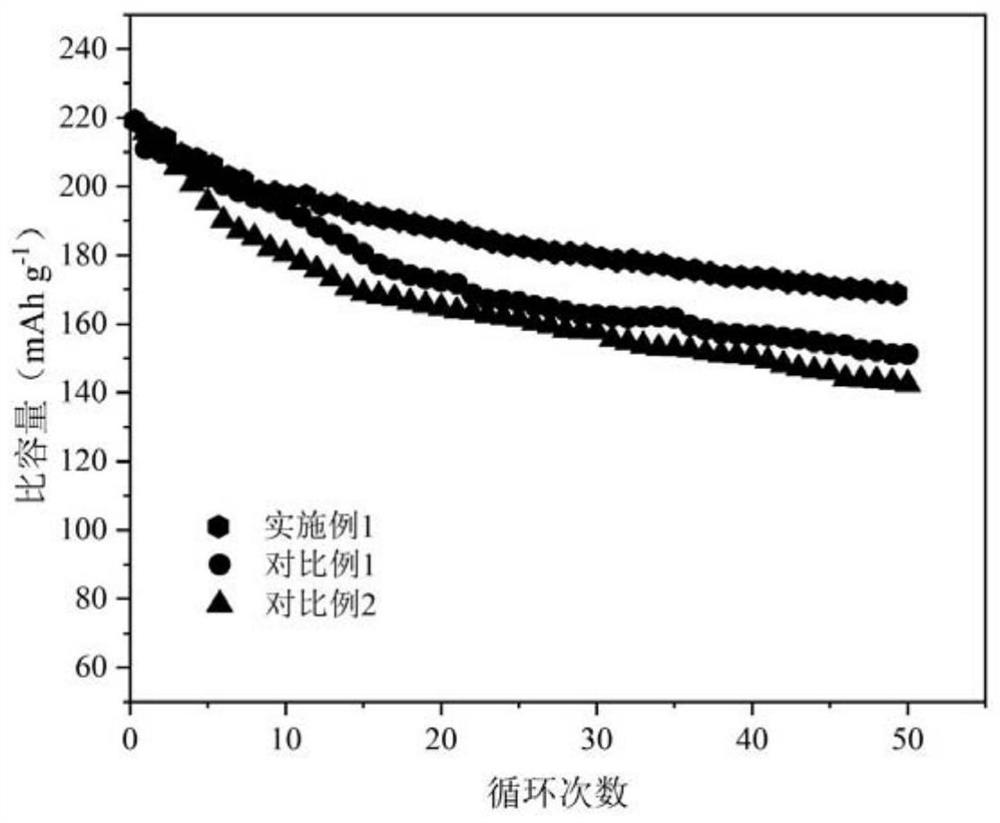

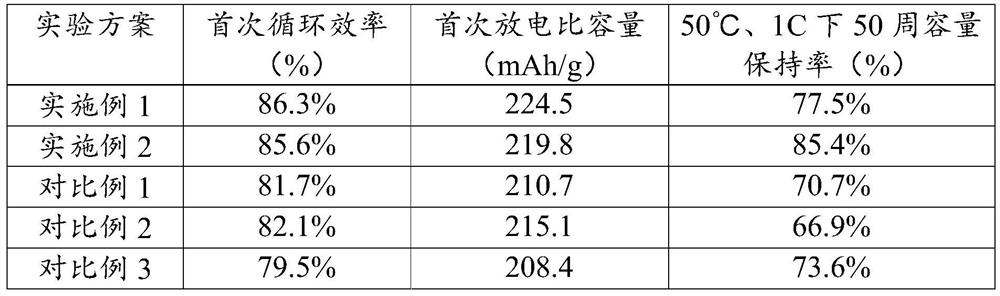

Examples

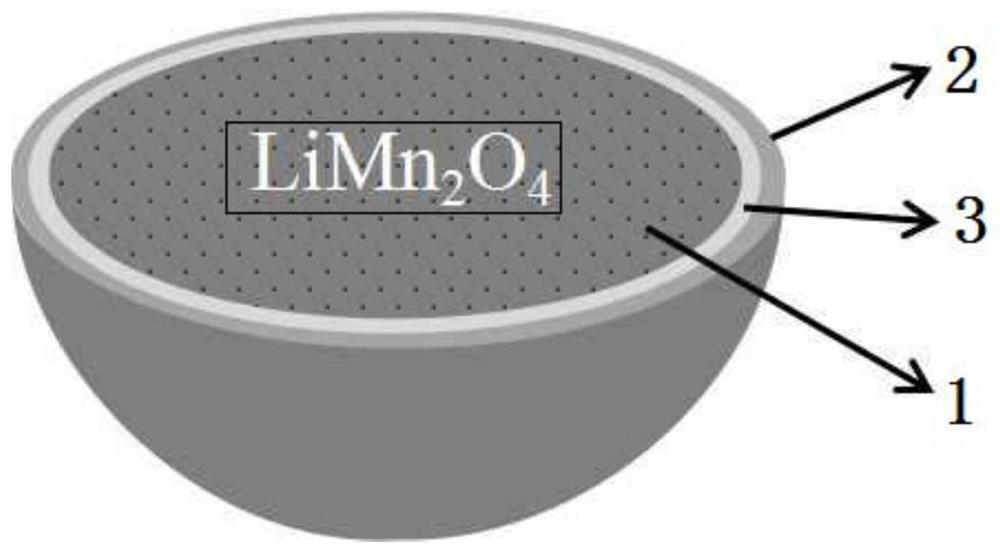

preparation example Construction

[0031]Another aspect of the present invention also provides a method for preparing the double-modified lithium manganate material described in any of the above technical solutions, comprising the following steps:

[0032] Configure an aqueous solution containing a certain proportion of lithium, manganese, and modifying elements, which is denoted as solution A;

[0033] Configure a solution of a certain concentration of organic complexing agent, denoted as solution B;

[0034] Adding the solution A to the solution B, controlling the reaction temperature and pH value until a gel-like substance is obtained;

[0035] The above gel-like substance was dried and ball-milled, and then in N 2 / O 2 The first-stage calcination and the second-stage calcination are carried out under a mixed atmosphere to obtain a double-modified lithium manganate material.

[0036] The preparation of the traditional double-modified lithium manganate material is to modify the finished positive electrode ...

Embodiment 1

[0045] (1) Weigh 11.32g, 88.68g, 1.50g of LiOH, MnAC, Al(NO 3 ) 3 Dissolved in 500ml deionized water, recorded as solution A;

[0046] (2) Take by weighing 112.02g of citric acid and dissolve it in 200ml of deionized water, and record it as solution B;

[0047] (3) Gradually add solution A to solution B, control the reaction temperature to 65°C and pH to 8.5, until a gel-like substance is formed;

[0048] (4) Dry and ball-mill the gel-like substance obtained in step (3), then place the powder material in a tube furnace for calcination, control the volume ratio of oxygen in the atmosphere to 0.86, and heat the first stage at 650°C. 8h; after annealing, cool down to 450°C and keep warm for 3h. A double-modified lithium manganate material coated with carbon and alumina on the surface and doped with aluminum can be obtained.

Embodiment 2

[0050] (1) Weigh 11.32g, 89.09g, and 1.20g of LiOH and MnSO respectively 4 , MgSO 4 Dissolved in 500ml deionized water, recorded as solution A;

[0051] (2) Take by weighing 85.78g of glutamic acid and dissolve in 200ml of deionized water, and record it as solution B;

[0052] (3) Gradually add solution A to solution B, control the reaction temperature to 50°C and pH to 10, until a gel-like substance is formed;

[0053] (4) Dry and ball-mill the gel-like substance obtained in step (3), then place the powder material in a tube furnace for calcination, control the volume ratio of oxygen in the atmosphere to 0.92, and heat it for 10 hours at a calcination temperature of 600°C for the first stage ; After annealing, cool down to 500°C and keep warm for 4h. A double-modified lithium manganate material coated with carbon and magnesium oxide and doped with magnesium can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com