Micron-order high-density erbium oxide microsphere and preparation method thereof

An erbium oxide, high-density technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems that cannot meet the application requirements of nuclear reaction control materials, low density of erbium oxide microspheres, template method is no longer applicable, etc. , to achieve the effect of easy popularization and application, good sphericity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

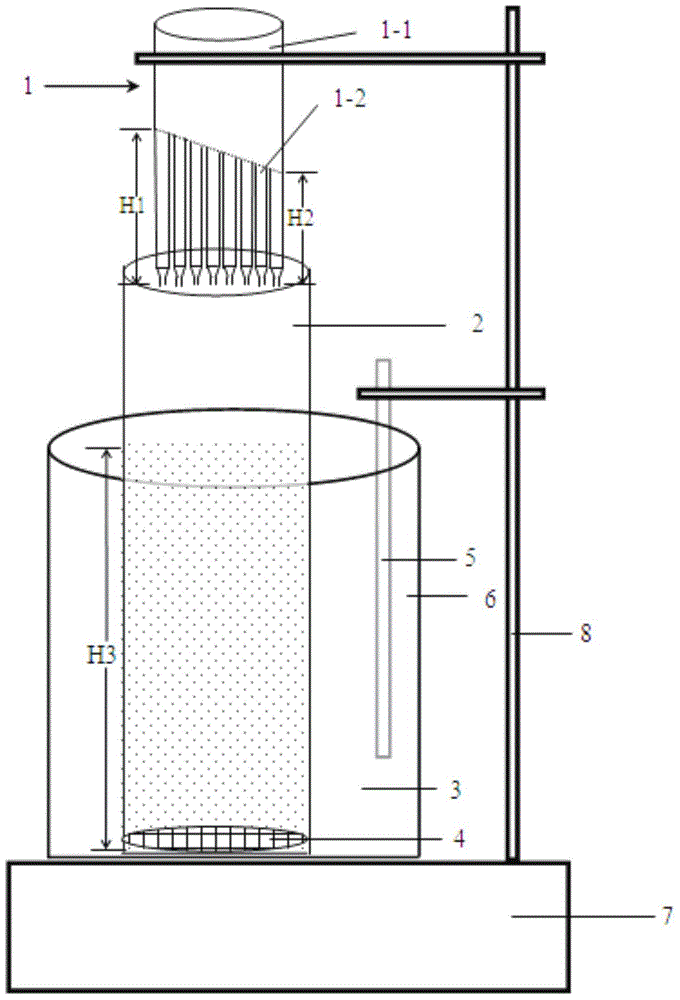

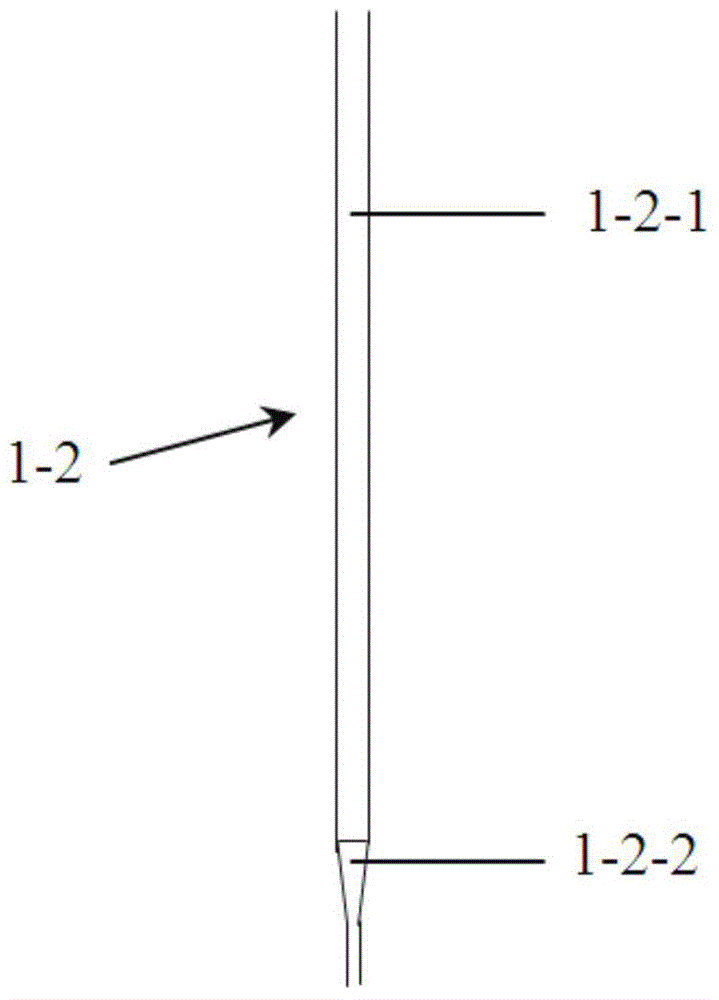

Method used

Image

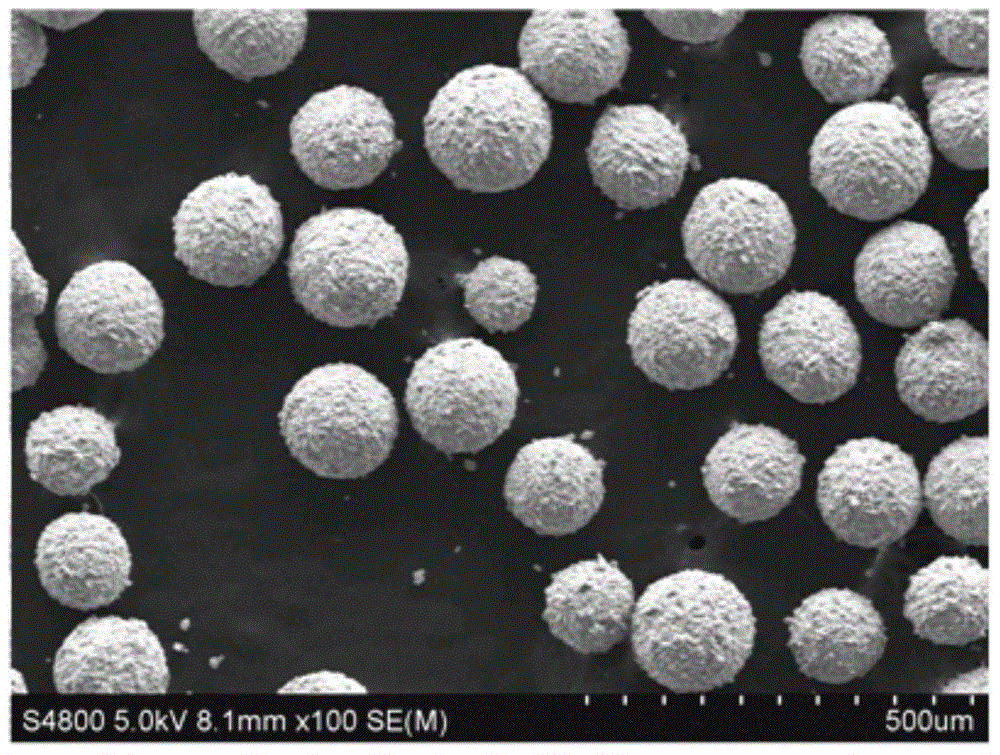

Examples

Embodiment 1

[0038] In this embodiment, the preparation method of micron-scale high-density erbium oxide microspheres is as follows:

[0039] (1) Preparation of slurry

[0040]Dissolve 2g of N,N-dimethylacrylamide and 0.13g of N,N′-methylenebisacrylamide in 5mL of deionized water, then add 1.25mL of polyacrylamide aqueous solution with a solid phase content of 40% (polyacrylamide The mass of the premix is 0.5g) to form a premix, adjust the pH of the premix to 10.3 with concentrated ammonia water, then add the premix and 100g of erbium oxide powder with a particle size of 3-7μm into the ball mill tank, and use zirconia as the grinding ball , control the ratio of ball to material to 1:1, use a ball mill to mill at a rate of 400r / min for 30min, the erbium oxide powder is evenly dispersed in the premixed solution, and then add 0.05g of ammonium persulfate into 1mL of deionized water to obtain a concentration of 2.19 ×10 -1 mol / L ammonium persulfate aqueous solution, the ammonium persulfate...

Embodiment 2

[0050] In this embodiment, the preparation method of micron-scale high-density erbium oxide microspheres is as follows:

[0051] (1) Preparation of slurry

[0052] Dissolve 4g of N,N-dimethylacrylamide and 0.2g of N,N′-methylenebisacrylamide in 6mL of deionized water, then add 1.25mL of polyacrylamide aqueous solution with a solid phase content of 40% (polyacrylamide The mass of the premix is 0.5g) to form a premix, adjust the pH of the premix to 10 with concentrated ammonia water, then add the premix and 100g of erbium oxide powder with a particle size of 3-7μm into the ball mill tank, and use zirconia as the grinding ball , control the ball-to-material ratio to 1.5:1, use a ball mill at a rate of 400r / min for 30min, the erbium oxide powder is evenly dispersed in the premixed liquid, and then take 0.04g of ammonium persulfate and add it to 1mL of deionized water to obtain a concentration of 1.75× 10 -1 The ammonium persulfate aqueous solution of mol / L, described ammonium ...

Embodiment 3

[0063] In this embodiment, the preparation method of micron-scale high-density erbium oxide microspheres is as follows:

[0064] (1) Preparation of slurry

[0065] Dissolve 4g of N,N-dimethylacrylamide and 0.2g of N,N′-methylenebisacrylamide in 6.5mL of deionized water, then add 1.5mL of polyacrylamide aqueous solution with a solid phase content of 40% (polyacrylamide The mass of amide is 0.6g) to form a premix, adjust the pH of the premix to 11 with concentrated ammonia water, then add the premix and 100g of erbium oxide powder with a particle size of 3-7μm into the ball mill tank, and use zirconia as the grinding ball, control the ratio of ball to material to 1.5:1, and use a ball mill at a rate of 400r / min for 30min to mill the erbium oxide powder evenly in the premixed solution, then take 0.04g of ammonium persulfate and add it to 1.25mL of deionized water to obtain a concentration of 1.41×10 -1 The ammonium persulfate aqueous solution of mol / L, described ammonium persul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com