105 DEG C low-smoke zero-halogen flame-retardant ethylene-propylene-diene monomer cable material and preparation method thereof

A technology of EPDM rubber and cable materials, applied in the direction of insulating cables, rubber insulators, cables, etc., can solve the problems of unsatisfactory wire and cable, poor high temperature resistance, low oxygen index, etc., and achieve excellent flame retardant effect and high temperature resistance Good sex, less smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

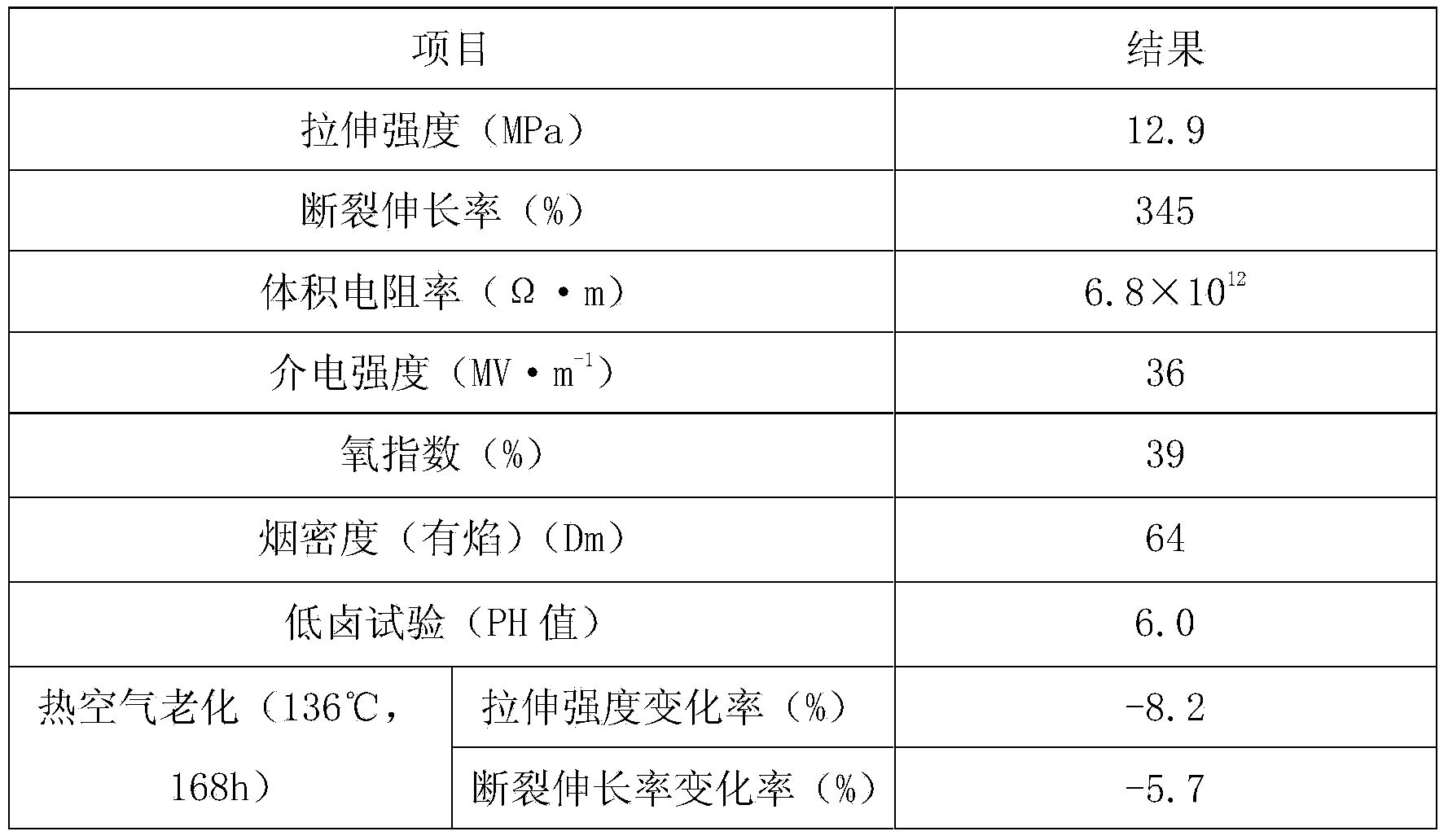

Examples

Embodiment Construction

[0013] A 105°C low-smoke, halogen-free, flame-retardant EPDM cable material, made of the following raw materials (kg): EPDM rubber 85, SG-4 type PVC resin 35, PBT resin 12, anti-aging agent DM1.5, antioxidant RD1, zinc oxide 2.5, titanium dioxide 4, microcrystalline paraffin 6, aluminum hydroxide 15, molybdenum trioxide 6, zinc borate 10, accelerator TMTD1.5, stearic acid 2, fumed silica 15. Ultrafine talcum powder 15, nano clay 10, dehydroacetic acid 1.5, acetyl triethyl citrate 8, tributyl citrate 6, sulfur 2, composite filler 4;

[0014] The preparation method of the composite filler is as follows: a. Take the raw materials of the following weight (kg): diatomite 10, wollastonite 8, nano-titanium dioxide 4, nano-silicon carbide 6, vinyl three (β-methoxyethoxy base) silane 2, lanthanum oxide 3, praseodymium oxide 1, epoxy soybean oil 10, dimethyl silicone oil 4, trimethylolpropane trimethacrylate 1.5, chlorinated paraffin 6, brucite powder 4, boron slag powder 2. Accelerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com