A reaction system and method for batch production of chlorinated polyvinyl chloride

A chlorinated polyvinyl chloride and reaction system technology, which is applied in the field of intermittent production of chlorinated polyvinyl chloride, can solve the problem of high failure rate of gas-solid phase activation-chlorination integrated fluidized bed device, aggravated separation, reuse or treatment section Burden, poor; Chinese patent application and other issues, to achieve the effect of improving energy efficiency, good use flexibility, and easy operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

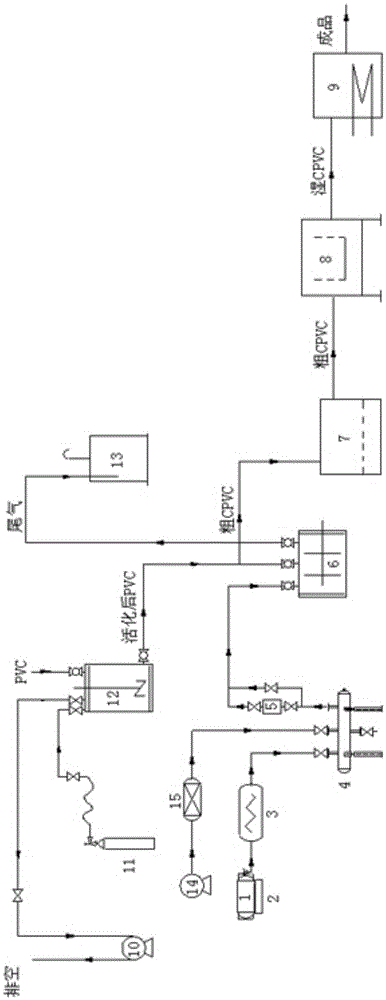

[0037] Such as figure 1 Shown is a schematic flowchart of an embodiment provided by the present invention. This chlorination reaction system comprises chlorination reactor 6 and plasma generator 12; Vacuum pump 10 and argon cylinder 11 constitute the auxiliary system of plasma generator 12; Chlorine cylinder 1, measuring scale 2, liquid chlorine vaporizer 3, chlorine buffer tank 4 And the chlorine gas flowmeter 5 constitutes a chlorine gas pretreatment system; the washing kettle 7, the centrifuge 8 and the drying box 9 constitute a chlorinated polyvinyl chloride treatment system; the tail gas absorption tank 13 is a tail gas absorption system; the blower 14 and the dryer 15 constitute a purging system . Wherein the chlorination reactor 6 adopts jacketed hot water heating mode, adopts an automatic temperature control device to control the reaction temperature, and the chlorine flow meter 5 adopts a float type flow meter.

[0038] Take a certain amount of polyvinyl chloride po...

Embodiment 2

[0040]Take a certain amount of polyvinyl chloride powder (chlorine content is 56.1%) and put it into the plasma generator 12, evacuate to 10Pa, then fill nitrogen to about 100Pa, and then evacuate to 10Pa; continue to fill nitrogen and keep the vacuum pump running, wait for When the vacuum degree is stable at about 50Pa, the discharge starts, and the power is 130W to generate nitrogen plasma to activate the polyvinyl chloride for 20 minutes; the activated polyvinyl chloride is transferred to the chlorination reactor 6 . Start the chlorination reactor 6 agitator, keep the rotating speed 45r / min, open the chlorine cylinder, after the liquid chlorine vaporizes, enter the chlorination reactor 6 through the chlorine buffer tank 4 and the flow meter 5, and start to feed hot water at the same time to heat it , keep the temperature at 70°C; feed chlorine gas three times the theoretical amount, and after 6 hours of reaction, stop the chlorine gas flow and stop heating at the same time, ...

Embodiment 3

[0042] Take a certain amount of polyvinyl chloride powder (chlorine content is 56.1%) and put it into the plasma generator 12, evacuate to 50Pa, then fill helium to about 500Pa, and then evacuate to 50Pa; continue to fill helium and keep the vacuum pump running , when the vacuum degree is stabilized at about 200Pa, the discharge starts, and the power is 180W to generate helium plasma to activate the polyvinyl chloride for 30 minutes; the activated polyvinyl chloride is transferred into the chlorination reactor 6. Start the agitator of the chlorination reactor 6, keep the rotating speed at 50r / min, open the chlorine cylinder, and after the liquid chlorine is vaporized, enter the chlorination reactor 6 through the chlorine buffer tank 4 and the flow meter 5, and start to feed hot water at the same time to heat it , keep the temperature at 90°C; feed 4 times the theoretical amount of chlorine gas, and after 3 hours of reaction, stop the chlorine gas flow and stop heating at the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com