Tissue- engineered cartilage graftimplant and preparation method thereof

A technique of tissue engineering and grafts, applied in the field of tissue engineered cartilage grafts and their preparation, and repair materials for cartilage defect repair, can solve the problems that cartilage defect repair has not been effectively solved, and an ideal has not been produced. , to achieve the effect of improving biomechanical properties, facilitating adhesion growth and vascularization, and improving healing speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of Nano-HA:

[0050] Hydroxyapatite was synthesized by sol-flocculation method. Preparation method: chemically synthesize the aqueous solution of calcium nitrate and ammonium phosphate, add a certain amount of ammonia water during the synthesis process, adjust the pH value of the solution to 8-13, add a dispersant, select a suitable stirrer, adjust the speed of the stirrer and stir Time to make it precipitate completely, then wash and filter, dry the precipitate at 80-120°C, and sinter at 600-800°C for 2-3 hours to obtain a powder with a particle size of less than 100nm that is similar to the composition of human bone tissue Nano-hydroxyapatite powder.

Embodiment 2

[0051] Embodiment 2, Preparation of PLLA

[0052] 1. Preparation of lactide: Take lactic acid and ZnO powder, gradually increase the temperature to dehydrate the lactic acid into lactide; then heat up and vacuumize to evaporate the light yellow lactide monomer, then use ethyl acetate as solvent to repeatedly wash and re- Purification by crystallization, suction filtration, and vacuum drying yielded colorless flaky pure lactide crystals.

[0053] 2. Synthesis of PLLA: pure lactide monomer, add stannous octoate initiator, vacuum dry at room temperature for a certain period of time, soak in a silicone oil bath for 3-5min, seal the reaction bottle, and shake it repeatedly when the temperature rises until the monomer just melts The reaction bottle was mixed evenly, and then timed to polymerize for a certain period of time to take out the reaction bottle.

[0054] 3. Purification of PLLA: Add dichloromethane to the crude PLLA to dissolve it completely, filter, add methanol to the...

Embodiment 3

[0057] Example 3: Preparation of tissue-engineered cartilage grafts:

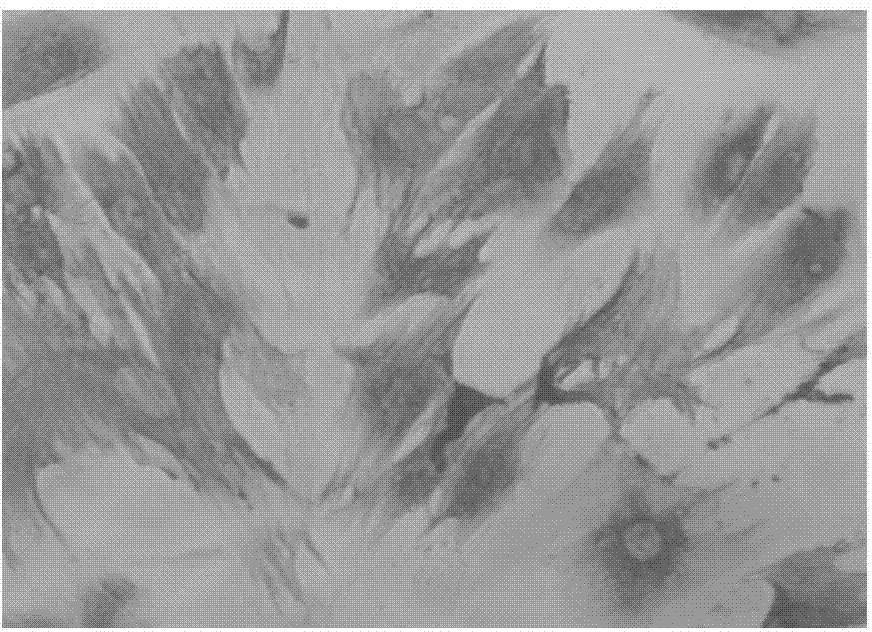

[0058] A tissue engineered cartilage graft, comprising a scaffold material and seed cells adhered to the scaffold material, the seed cells are chondrocytes induced and differentiated by BMSCs through TGF-β1; the preparation method of the tissue engineered cartilage graft as follows:

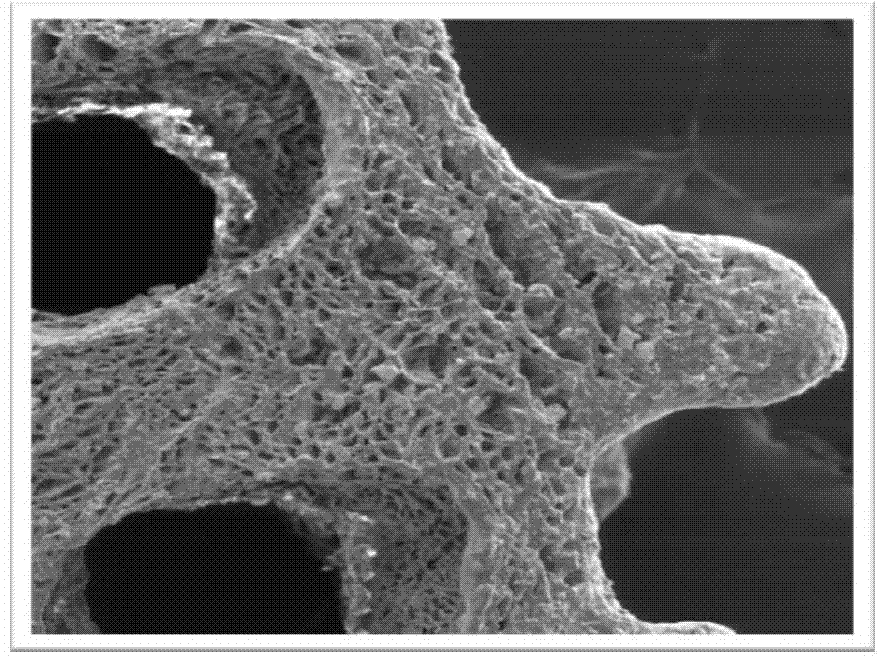

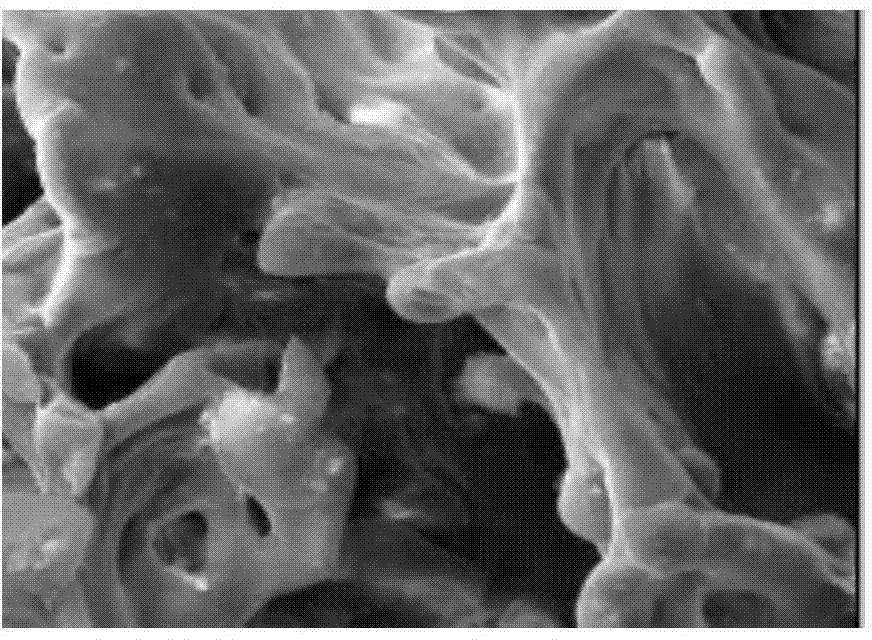

[0059] 1. Preparation of Nano-HA / PLLA cartilage scaffold material

[0060] (1), Preparation of Nano-HA / PLLA cartilage scaffold material:

[0061] (a), dissolving Nano-HA and PLLA in an organic solvent in a mass ratio of 1:4, and mixing uniformly to obtain a prepared biological material;

[0062] (b) Form parallel ice lines with intervals by RIPF process, the filling speed of RIPF process is 20mm / s, and the filling speed determines the interval between parallel ice lines;

[0063] (c), filling the prepared biological material into the interval between the ice lines, and scraping the surface filled with the biological mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com