Method for preparing ultrathin metal powder

A technology of ultra-fine metal powder and metal, which is applied in the field of preparation of ultra-fine metal powder, which can solve the problems of large particle size and low yield, and achieve the effect of small gas consumption and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing ultrafine pure tin powder, comprising the following steps:

[0031] A. Smelting, placing metal tin in an induction melting furnace and melting it into a molten metal at a temperature of 250-300°C;

[0032] B. Atomization, the melt obtained in step A is leaked into the atomizer through a leak bag with an aperture of 5.0mm at a flow rate of 10 kg / min for atomization. Nitrogen is used as the atomization medium during atomization. The pressure is 4.5MPa, and the medium ejection speed is 510m / s;

[0033] C. cooling, placing the tiny tin droplets gained in step B in water and water mist for cooling to obtain tiny tin particles;

[0034] D. Classifying the fine tin particles obtained in step C according to different particle size requirements, to obtain final product.

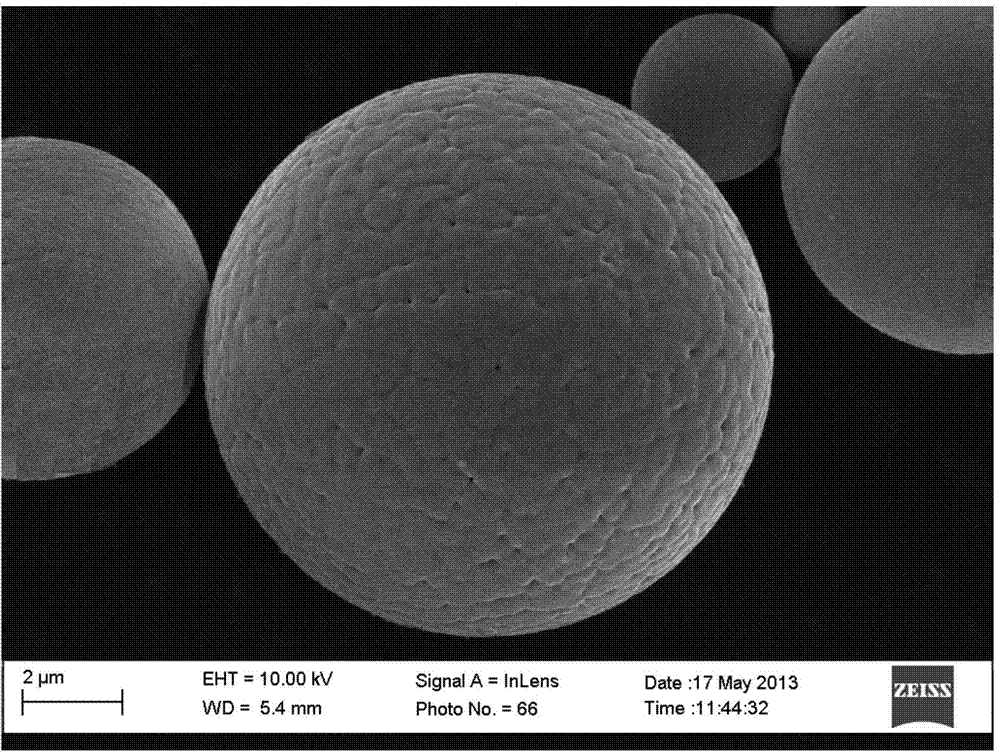

[0035] The micrograph of the obtained powder is shown in figure 1 As shown, the average particle size is 10.2 μm, of which pure tin powder with a particle size below 10 μm accounts for...

Embodiment 2

[0037] A method for preparing ultrafine pure copper powder, comprising the following steps:

[0038] A. Melting, put the red copper in the induction melting furnace, and melt it into a molten metal at a temperature of 1150°C;

[0039] B. impurity removal, add 2% Ca-Al-Si-Li-Fe refining agent of red copper quality in step A gained copper liquid, stir for 15 minutes, leave standstill for 5 minutes, remove the scum above the copper liquid, so Repeat 3 times to get pure copper liquid (impurity content 85ppm);

[0040] C. Atomization, the melt obtained in step B is leaked into the atomizer through a leak bag with an aperture of 5.0mm at a flow rate of 15 kg / min for atomization. Nitrogen is used as the atomization medium during atomization. The pressure is 4.2MPa, and the medium ejection speed is 490m / s;

[0041] D. cooling, placing the fine copper droplets obtained in step C in a liquid nitrogen mist cooling medium for cooling to obtain fine pure copper particles;

[0042] E. cl...

Embodiment 3

[0045] A method for preparing ultrafine iron-silicon soft magnetic powder, comprising the following steps:

[0046] A. Melting, the mixture of Fe and Si (the Si content is 6.5wt.%, Fe is the balance) is placed in an induction melting furnace, and melted into a molten metal at a temperature of 1600 ° C;

[0047]B. Impurity removal, add 2% Ca-Al-Si-Li-Fe refining agent of the total mass of Fe and Si mixture to the alloy melt obtained in step A, stir for 15 minutes, let stand for 5 minutes, and remove the alloy melt For the scum above, repeat this 3 times to get a pure iron-silicon alloy melt (the impurity content is 89ppm);

[0048] C. Atomization, the melt obtained in step B is leaked into the atomizer through a leak bag with an aperture of 5.0mm at a flow rate of 12 kg / min for atomization. Water is used as the atomization medium during atomization, and the atomization water pressure It is 120MPa, the water flow rate is 2.35 liters per second, and the water jetting speed is 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com