Device and method for air-blowing vacuum membrane distillation

A decompression membrane distillation and negative pressure technology, applied in the direction of total evaporation, can solve the problems of high energy consumption, high system requirements, low reliability, etc., to reduce vacuum requirements, improve mass transfer efficiency, and reduce equipment The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

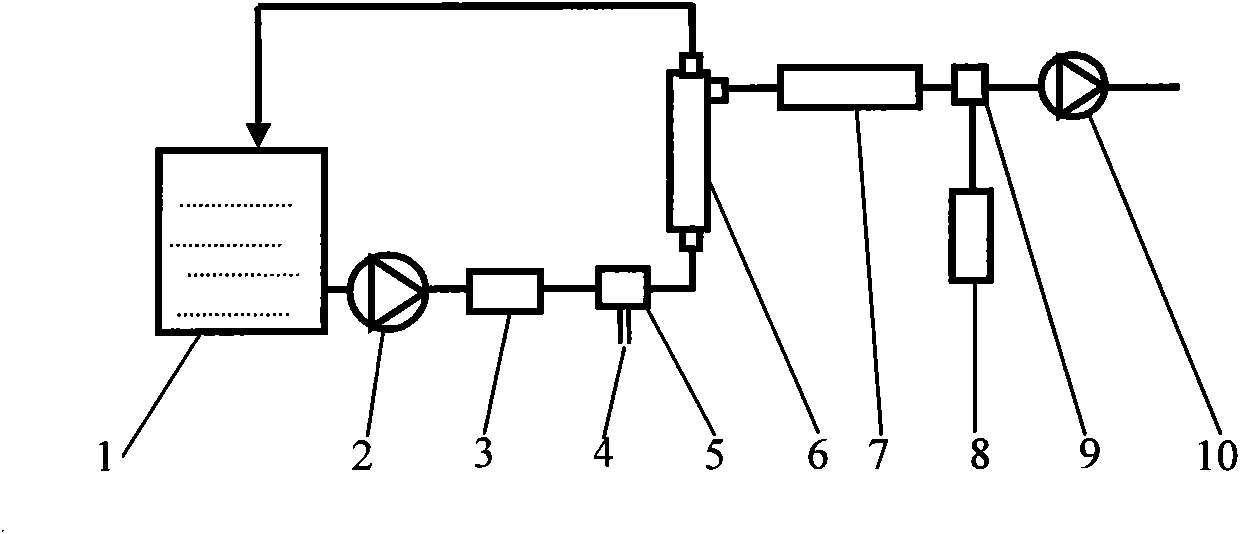

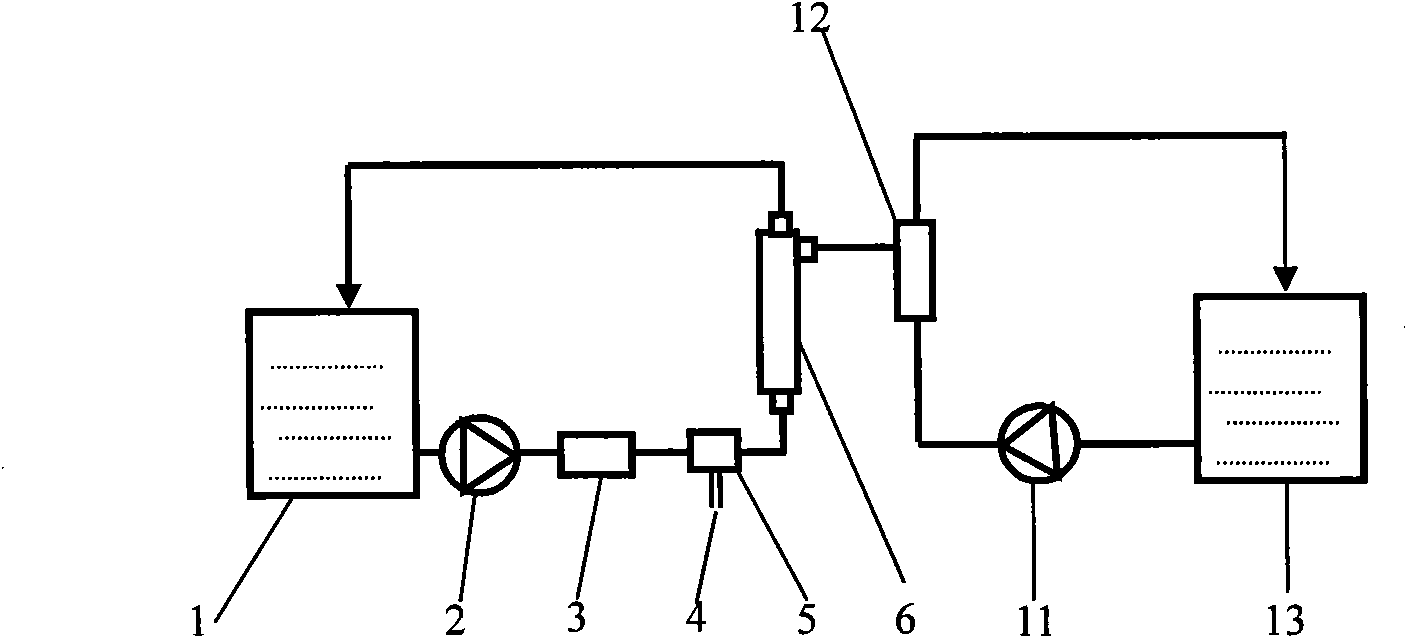

[0024] The system of the present invention is as figure 1 , figure 2 shown. Seen from the side of the raw water, the blown vacuum membrane distillation device of the present invention includes the following parts connected in sequence:

[0025] A water tank 1 provided on the raw water side; a water pump 2 connected to the water tank; a heater 3 connected to the outlet of the water pump; a gas-liquid mixer 5 connected downstream of the water pump 2 for mixing compressed air and liquid to form a gas-liquid mixed fluid ; The compressed air inlet 4 is arranged on the mixer 5 for blowing low-pressure compressed air into the raw water; the hydrophobic membrane module 6 connected to the outlet of the mixer 5 handles the gas-liquid mixed fluid.

[0026] For the heater 3, if the raw water temperature meets the requirements, the heater 3 can also be canceled.

[0027] In addition, raw water can be preheated or unheated or directly heated to the desired temperature.

[0028] A negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com