Method for preparing monocrystal graphene

A single-crystal graphene and semiconductor technology, applied in the direction of single-crystal growth, single-crystal growth, chemical instruments and methods, etc., can solve problems such as high process requirements, complex equipment and control process, etc., to reduce the concentration of carbon sources and reduce carbon Effect of source density, stringency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

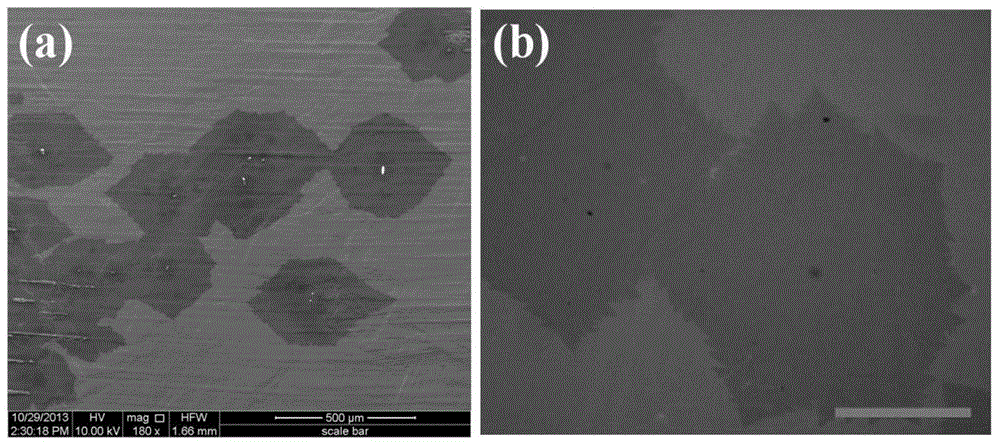

Image

Examples

Embodiment 1

[0028] The present embodiment provides a kind of method for preparing single crystal graphene, comprises the following steps:

[0029] S1: A laminated structure is obtained by disposing a quartz layer 2 on the upper surface and the lower surface of the copper foil 3, and the quartz layer 2 completely covers the copper foil 3.

[0030] S2: The laminated structure is placed in a closed container that is evacuated from the air, such as figure 1 As shown, the closed vessel is the quartz tube 4 shown in the figure.

[0031] S3: Introduce hydrogen and argon into the closed container, and heat the closed container to 1050° C. to make the copper foil in a molten state; wherein the flow rate of hydrogen gas is 200 sccm, and the flow rate of argon gas is 1000 sccm.

[0032] S4: continuously annealing the laminated structure at a temperature of 1050° C. for 1.5 hours.

[0033] S5: Pass methane and hydrogen gas into the closed vessel to grow single crystal graphene for 25 minutes, where...

Embodiment 2

[0037] The present embodiment provides a kind of method for preparing single crystal graphene, comprises the following steps:

[0038] S1: A laminated structure is obtained by arranging a sapphire layer on the upper surface and the lower surface of the copper foil, and the sapphire layer completely covers the copper foil.

[0039] S2: placing the laminated structure in a quartz tube evacuated of air.

[0040] S3: Introduce hydrogen and argon into the quartz tube, and heat the closed vessel to 1000° C. to make the copper foil in a molten state; wherein the flow rate of hydrogen gas is 150 sccm, and the flow rate of argon gas is 750 sccm.

[0041] S4: continuously annealing the laminated structure at a temperature of 1000° C. for 1.5 hours.

[0042] S5: Pass methane and hydrogen gas into the closed vessel to grow single crystal graphene for 30 minutes, wherein the flow rate of methane and hydrogen gas is 150 sccm.

[0043] S6: Take out the laminated structure, lower the temper...

Embodiment 3

[0046] The present embodiment provides a kind of method for preparing single crystal graphene, comprises the following steps:

[0047] S1: A silicon layer is provided on the upper surface and the lower surface of the copper foil to obtain a laminated structure, and the silicon layer completely covers the copper foil.

[0048] S2: placing the laminated structure in a quartz tube evacuated of air.

[0049] S3: Introduce hydrogen and argon into the quartz tube, and heat the closed vessel to 1025° C. to make the copper foil in a molten state; wherein the flow rate of hydrogen gas is 130 sccm, and the flow rate of argon gas is 850 sccm.

[0050] S4: continuously annealing the laminated structure at a temperature of 1030° C. for 2 hours.

[0051] S5: Pass methane and hydrogen gas into the closed vessel to grow single crystal graphene for 20 minutes, wherein the flow rate of methane and hydrogen gas is 180 sccm.

[0052] S6: Take out the stacked structure, lower the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com