Gas reverse-circulation well-drilling method

A reverse circulation and gas technology, applied in the field of drilling and oil drilling, can solve the problems of reduced comprehensive economic benefits, restrictions on the application and development of gas drilling, high fuel costs, etc., to reduce equipment costs and maintenance costs, and reduce downhole complexity , the effect of fast drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

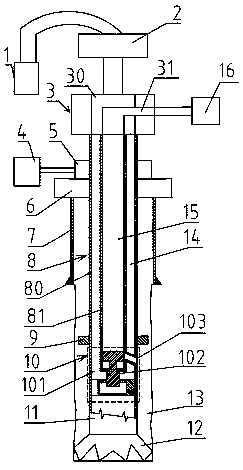

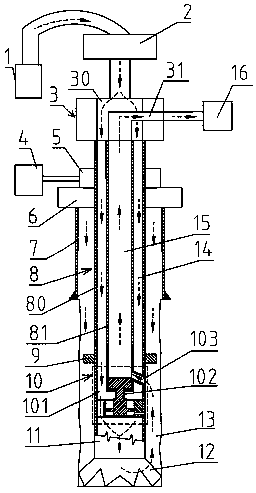

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] Refer to the attached figure 1 and 2 , a drilling system used in a gas reverse circulation drilling method includes: a drilling pump set, a top drive 2, a top drive adapter 3, a rotating blowout preventer diversion device 5, a blowout preventer set 6, casing 7, and a double-walled drill pipe 8. Flow channel conversion device 10 , conventional drilling tool 11 and drill bit 12 . Wherein: the double-wall drill rod 8 is composed of a concentric inner drill rod 81 and an outer drill rod 80, an annular gap B14 is formed between the inner drill rod 81 and the outer drill rod 80, and the lower ends of the inner drill rod 81 and the outer drill rod 80 are There is a hole D103 in the radial direction of the inner part, and the hole D103 is connected with the inner hole A15 of the double-wall drill pipe 8 and the outer annular gap A13. The inside of the inner drill pipe 81 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com