Pectinase preparation producing Aspergillus japonicus PJ01 and enzyme production method

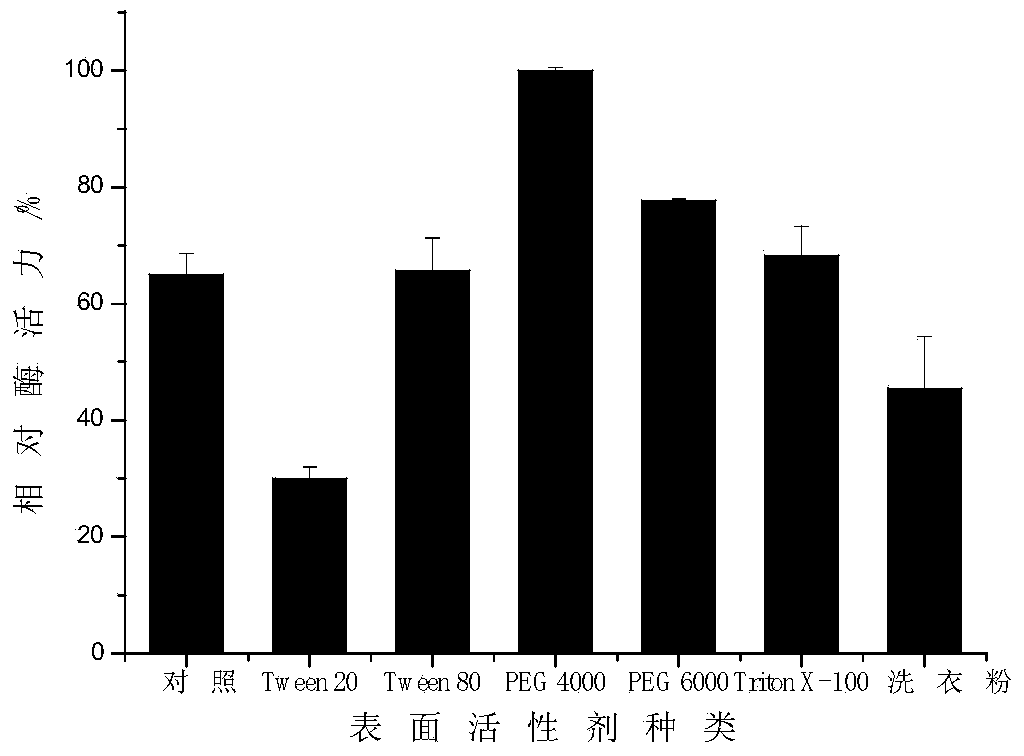

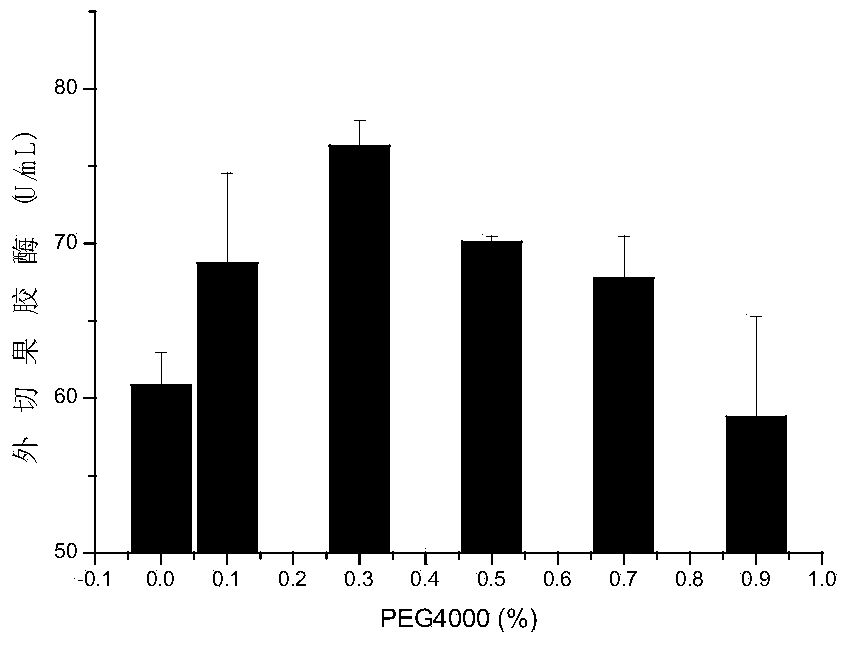

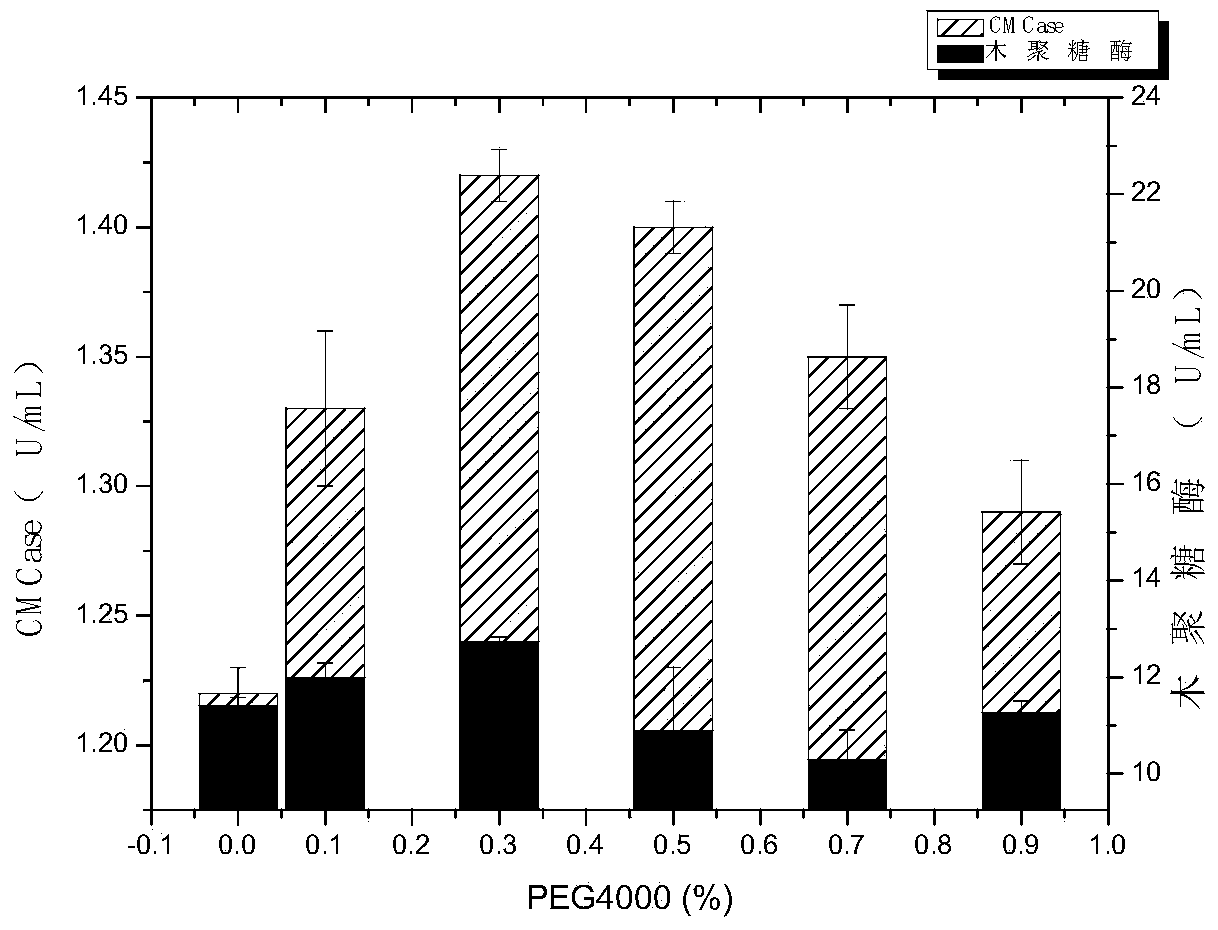

A pectinase preparation, the technology of PJ01, is applied in the field of enzyme production in which surfactants improve its enzyme activity, and achieves the effects of full utilization, rapid growth and production of enzymes, and simple and feasible fermentation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: culture medium preparation

[0029] Preparation of orange peel powder: dry the orange peel at 50-60°C, crush it through a 10-20 mesh sieve, and place it in a glass drier for later use.

[0030] Slant medium (g / L): peeled potato 200, glucose 20, agar 20, pH natural, water 1000mL; sterilize at 121°C for 15 minutes, place the test tube on the slope; inoculate after cooling, and culture at 35°C for 4 days.

[0031] Fermentation medium (g / L): orange peel powder 20, NaNO 3 5,K 2 HPO 3 1, KCl0.5, MgSO 4 ·7H 2 O0.5, FeSO 4 ·7H 2 O0.01.

Embodiment 2

[0032] Embodiment 2: preparation of spore suspension

[0033] Aspergillus japonicus spores were washed with physiological saline containing 0.1wt% Tween-80 to make a spore suspension, counted with a hemocytometer and placed in a 4°C refrigerator for storage.

Embodiment 3

[0034] Embodiment 3: Screening and identification method of Aspergillus japonicus PJ01

[0035] a. Preliminary screening: samples were collected from 15 places such as Yuelu Mountain soil samples, orange orchard soil samples, kiwifruit orchard soil samples, Yuelu Mountain rotten branches, and fruit market rotten oranges. Take 5g of the sample and add it to a 250mL Erlenmeyer flask containing 100mL of fermentation medium. After enrichment culture at 35°C and 170r / min shaker for 3 days, take 1mL of the culture solution and dilute to 10 spores. -6 -10 -8 pcs / mL, take 0.2mL dilution and spread evenly on the screening plate medium with pectin, carboxymethylcellulose sodium (CMC-Na) and xylan as carbon source respectively, after culturing for 3 days, use Congo red A total of 20 mold strains with large transparent circles were screened out by the staining method, and the strains were further plated to purify the strains, and finally transferred to PDA slant medium for culture and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com