Production method of polylactic acid-trimethylene carbonate nano-fiber film

A technology of methyl carbonate and nanofibers, which is applied in fiber treatment, spinning solution preparation, textiles and papermaking, etc. It can solve the problems of low shape transition temperature, low shape recovery rate, low shape recovery rate of polylactic acid, and unsuitability. To achieve the effect of solving stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 0.2 g of PDLLA-PTMC (DLLA:TMC=50:50, molar ratio) in 0.7 g of DMF and 0.9 g of DCM with an electronic analytical balance, and stir until completely dissolved to obtain the final PDLLA-PTMC PDLLA-PTMC / DMF / CH at a concentration of 11.1% (w / w) 2 CL 2 spinning solution.

[0032] (2) Use a 10mL syringe and a needle with an inner diameter of 1.2mm to extract PDLLA-PTMC / DMF / CH 2 CL 2 The spinning solution was fixed on the electrospinning device for electrospinning. The parameters were: the injection rate of the spinning solution was 2mL / h, the voltage was 15kV, the receiving distance was 15cm, the ambient temperature was 23°C, and the ambient relative humidity was 40%. Aluminum foil was used as the receiving device, and the fiber membrane was spun for 2 hours. The collected fiber membrane was dried in a vacuum oven for 24 hours to obtain a PDLLA-PTMC (50:50) shape memory fiber membrane with a fiber structure.

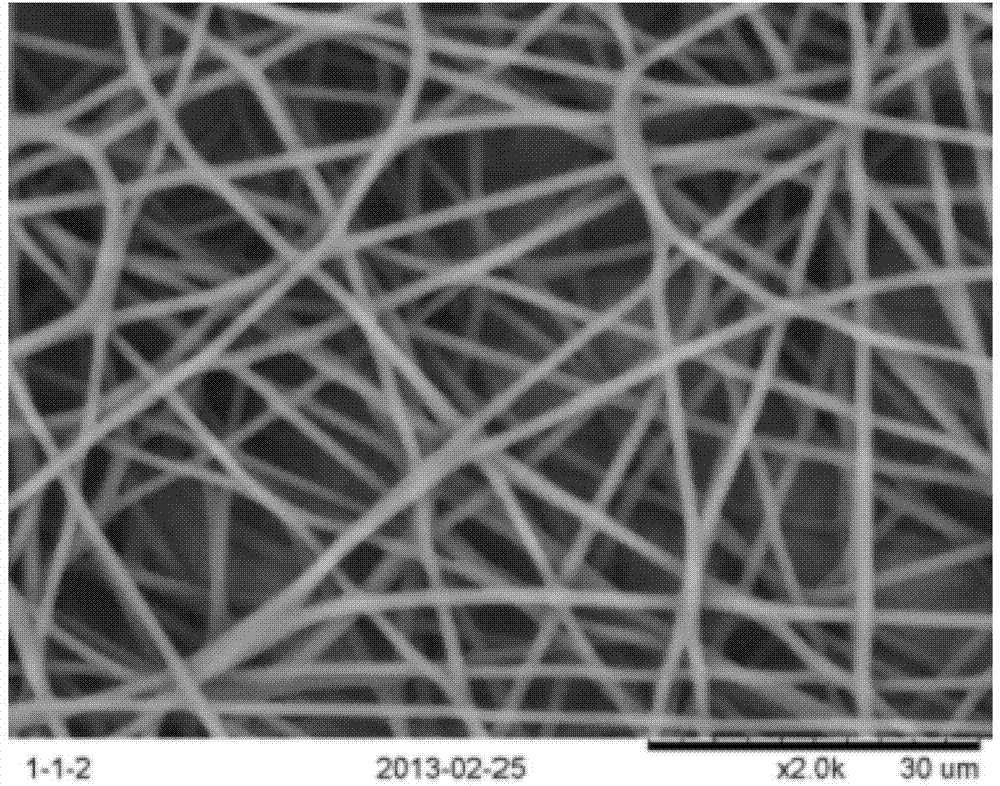

[0033] The scanning electron micrograph of the PD...

Embodiment 2

[0035] (1) Weigh 0.4g of PDLLA-PTMC (DLLA:TMC=70:30, molar ratio) and dissolve it in 0.8g of DMF and 0.8g of DCM with an electronic analytical balance, and stir until completely dissolved to obtain the final PDLLA-PTMC PDLLA-PTMC / DMF / CH at a concentration of 20% (w / w) 2 CL 2 spinning solution.

[0036] (2) Use a 10mL syringe and a needle with an inner diameter of 1.2mm to extract PDLLA-PTMC / DMF / CH2 CL 2 The spinning solution is fixed on the electrospinning device for electrospinning. The parameters are: the injection rate of the spinning solution is 1.5mL / h, the voltage is 14kV, the receiving distance is 20cm, the ambient temperature is 26°C, and the ambient relative humidity is 45%. . Aluminum foil was used as the receiving device, and the fiber membrane was spun for 2 hours. The collected fiber membrane was dried in a vacuum oven for 24 hours to obtain a PDLLA-PTMC (70:30) shape memory fiber membrane with a fiber structure.

[0037] The scanning electron micrograph of th...

Embodiment 3

[0039] (1) Weigh 0.45g of PDLLA-PTMC (DLLA:TMC=80:20, molar ratio) with an electronic analytical balance and dissolve it in 0.5g of DMF and 1.1g of DCM, and stir until completely dissolved to obtain the final PDLLA-PTMC PDLLA-PTMC / DMF / CH at a concentration of 21.9% (w / w) 2 CL 2 spinning solution.

[0040] (2) Use a 10mL syringe and a needle with an inner diameter of 1.2mm to extract PDLLA-PTMC / DMF / CH 2 CL 2 The spinning solution was fixed on the electrospinning device for electrospinning. The parameters were: the injection rate of the spinning solution was 2mL / h, the voltage was 16kV, the receiving distance was 16cm, the ambient temperature was 25°C, and the ambient relative humidity was 46%. Aluminum foil was used as the receiving device, spinning for 2 hours, and the collected fiber membrane was dried in a vacuum oven for 24 hours to obtain a PDLLA-PTMC (80:20) shape memory fiber membrane with a fiber structure.

[0041] The scanning electron micrograph of the PDLLA-PTMC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com