A magnetothermal responsive shape memory hierarchical porous nanocomposite bioscaffold based on 3D printing emulsion and its preparation and application

A 3D printing and nano-composite technology, which is applied in medical science, prosthesis, additive processing, etc., can solve the problems of photoinitiator bio-incompatible substance residues, limit the application of scaffolds, etc., and achieve good compatibility and dispersion , low equipment requirements and controllable preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Hydrophobic modification of ferroferric oxide nanoparticles: disperse 2 parts by mass of ferric oxide nanoparticles in 30 parts by volume of dichloromethane in an ice-water bath, then add 20 parts by volume of PLLA-COOH dichloromethane solution (Containing 2 mass parts PLLA-COOH, molecular weight 1.5×10 3 g / mol) mixed, ultrasonically dispersed and mixed evenly, and dried at room temperature to remove the solvent, and then the dry mixture was placed in a nitrogen atmosphere tube furnace for heat treatment at 200°C for 24h to obtain hydrophobically modified ferric oxide nanoparticles.

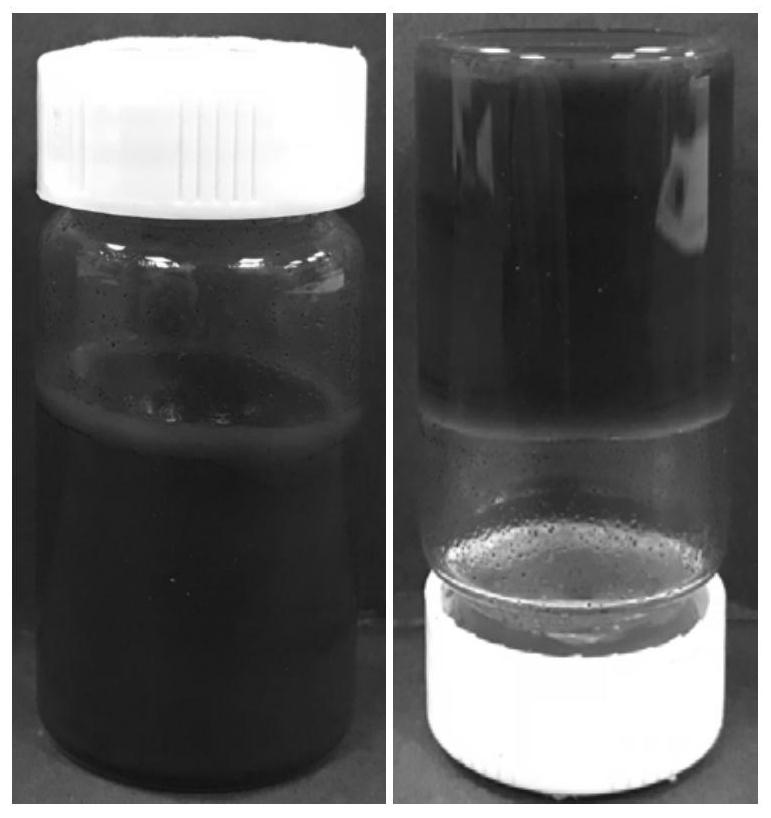

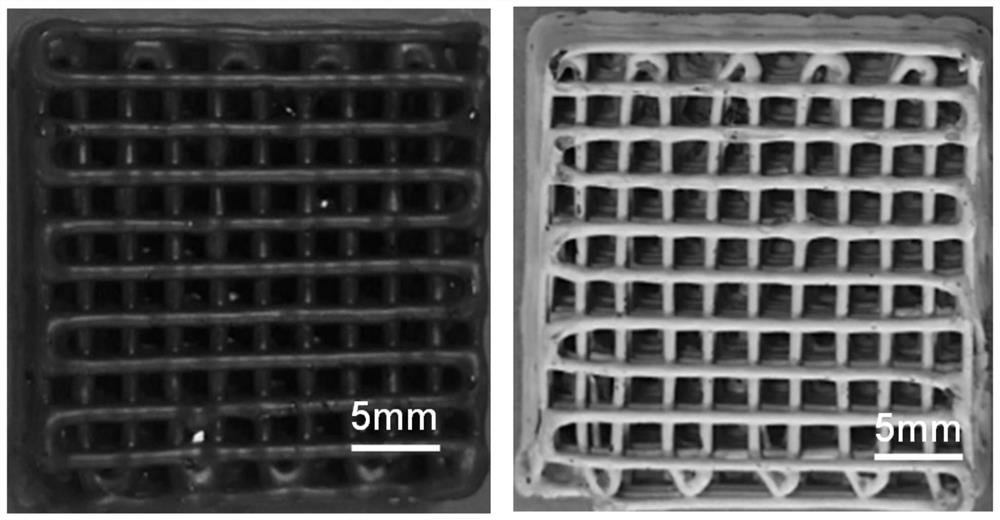

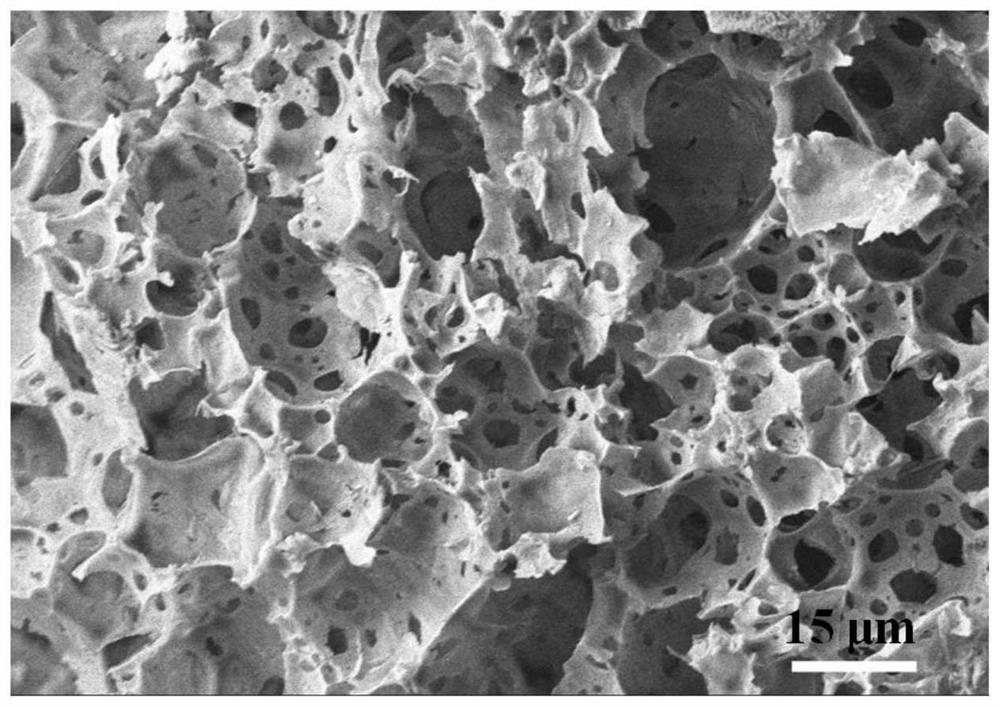

[0053] (2) Preparation of water-in-oil viscous Pickering emulsion: in an ice-water bath, 3 parts by volume of dichloromethane suspension was prepared by ultrasonication for 30 minutes, that is, the oil phase, in which polylactic acid-trimethylcarbonate Copolymer (molecular weight 5×10 4 g / mol, wherein the mol ratio of lactic acid and trimethylene carbonate is 70:30), the mass volume f...

Embodiment 2

[0057] (1) Hydrophobic modification of ferroferric oxide nanoparticles: disperse 2 parts by mass of ferric oxide nanoparticles in 30 parts by volume of dichloromethane in an ice-water bath, then add 20 parts by volume of PLLA-COOH dichloromethane solution (Containing 2 mass parts PLLA-COOH, molecular weight 5×10 3 g / mol) mixed, ultrasonically dispersed and mixed evenly, and dried at room temperature to remove the solvent, and then the dry mixture was placed in a nitrogen atmosphere tube furnace for heat treatment at 200°C for 30h to obtain modified ferric oxide nanoparticles.

[0058] (2) Preparation of water-in-oil viscous Pickering emulsion: in an ice-water bath, 4 parts by volume of dichloromethane suspension was prepared by ultrasonication for 30 minutes, i.e. the oil phase, in which polylactic acid-trimethylcarbonate Copolymer (molecular weight 5.3×10 4 g / mol, wherein the mol ratio of lactic acid and trimethylene carbonate is 80:20), the mass volume fraction of modified ...

Embodiment 3

[0061] (1) Hydrophobic modification of ferric oxide nanoparticles: disperse 2 parts by mass of ferric oxide nanoparticles in 30 parts by volume of dichloromethane in an ice-water bath, then add 20 parts by volume of PLLA-COOH dichloromethane solution (Containing 1.5 mass parts PLLA-COOH, molecular weight 1.5×10 3 g / mol) mixed, ultrasonically dispersed and mixed evenly, and dried at room temperature to remove the solvent, and then the dry mixture was placed in a nitrogen atmosphere tube furnace for heat treatment at 200°C for 30h to obtain modified ferric oxide nanoparticles.

[0062] (2) Preparation of water-in-oil viscous Pickering emulsion: in an ice-water bath, 6 parts by volume of dichloromethane suspension was prepared by ultrasonication for 30 minutes, that is, the oil phase, in which polylactic acid-glycolic acid-trimethyl Based carbonate copolymer (molecular weight is 3×10 4 g / mol, wherein the mol ratio of lactic acid, glycolic acid, and trimethylene carbonate is 80:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com