In-gas discharge dressing and truing method for large-particle diamond grinding wheel

A diamond grinding wheel and diamond technology, applied in metal processing equipment, parts of grinding machine tools, abrasive surface adjustment devices, etc., can solve the problems of low efficiency of mechanical dressing, and achieve the effects of green environmental protection, avoiding arc discharge, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

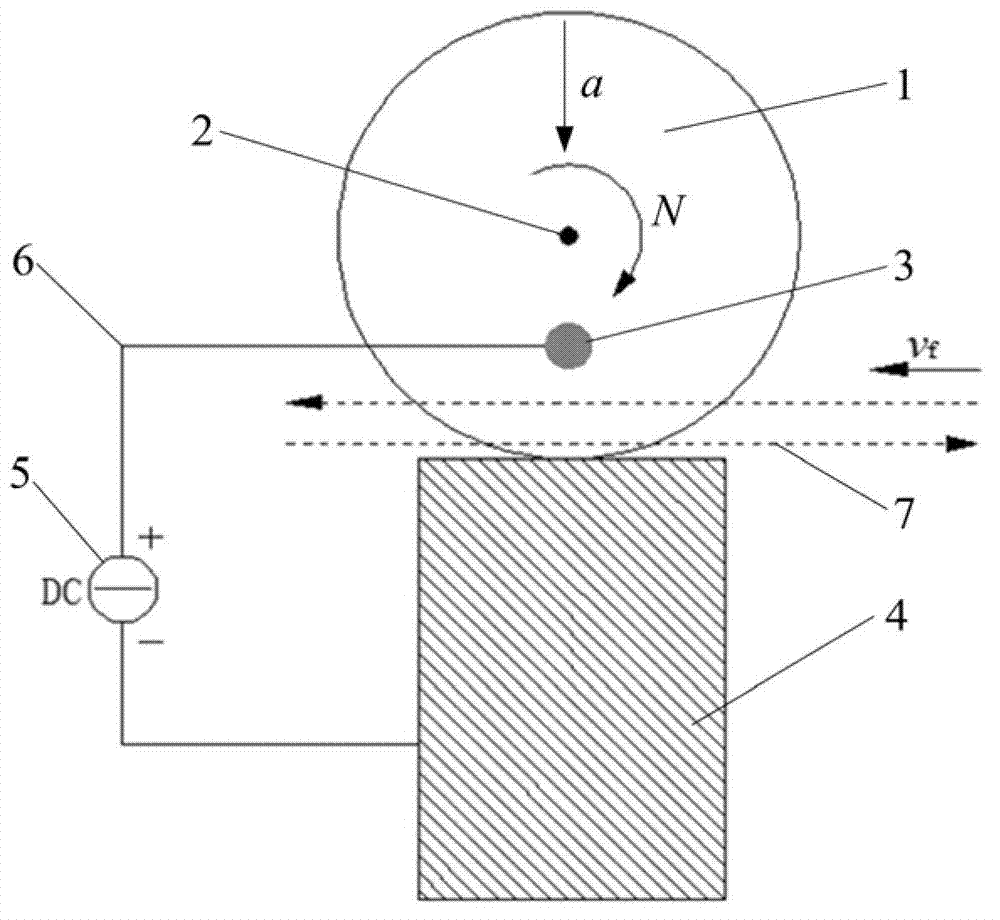

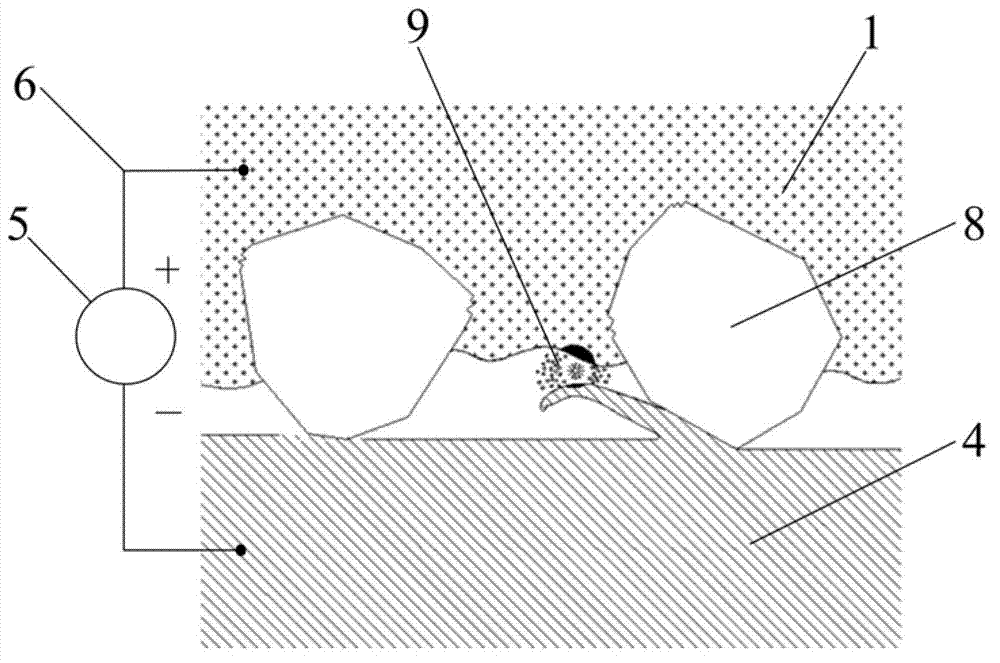

[0032] A diamond grinding wheel (150 mm in diameter, 2.5 mm in thickness) 1 is installed on the grinding wheel shaft 2 of a CNC precision grinding machine (SMRART B818); a rectangular copper electrode (51 mm in width, 12.9 mm in thickness) 4 is fixed on a horizontal table, and Its height direction is perpendicular to the axis of the grinding wheel; the particle size of the diamond grinding wheel 1 is 46 mesh, the concentration is 100%, the metal bond is bronze, and the rectangular copper electrode 4 is copper.

[0033] Connect diamond grinding wheel 1, copper electrode 4, graphite brush 3, Zhaoxin RXN-605D DC power supply (or pulse power supply of Hengwei Technology MC-150 / 10) 5 and wire 6 to form a discharge circuit through wire 6;

[0034] Such as figure 1 As shown, the diamond grinding wheel makes a linear reciprocating motion on the surface of the copper electrode 7, the grinding wheel is connected to the positive pole of the power supply, and the copper electrode is conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com