Gallium nitride nanowire and preparation method thereof

A technology of gallium nitride nanowires and gallium oxide is applied in the field of gallium nitride nanowires and their preparation, which can solve the problems of inability to prepare gallium nitride nanowires, and achieve rich exposed surfaces, good crystallinity, and wide application value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

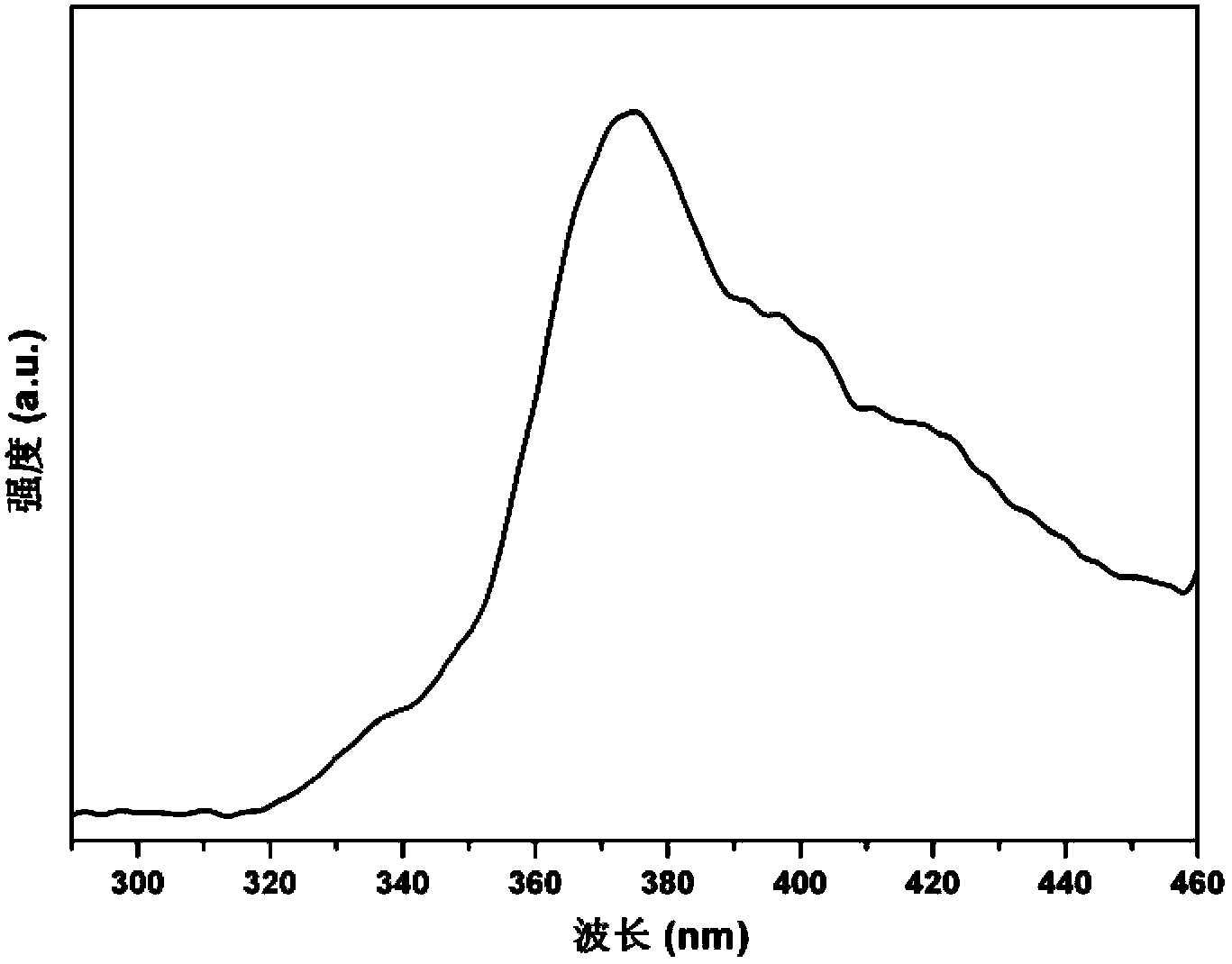

Image

Examples

preparation example Construction

[0024] According to the aforementioned method for preparing gallium nitride nanowires of the present invention, as long as it is ensured that under normal pressure, simple gallium, gallium oxide, and a gas containing ammonia are chemically carried out on a substrate loaded with a catalyst for preparing gallium nitride nanowires. Vapor phase precipitation can fully realize the purpose of the present invention.

[0025] In the present invention, the optional range of the flow rate of the gas containing ammonia is relatively wide, and the inventors of the present invention found in the research process that the gas containing ammonia should be reasonably controlled in the process of preparing gallium nitride nanowires. The flow rate measured by ammonia gas can make the prepared gallium nitride nanowires have the advantages of good monodispersity, regular and complete exposed surface. Therefore, for the present invention, the flow rate of the ammonia-containing gas is preferably 3...

Embodiment approach

[0035] According to a preferred embodiment of the present invention, the present invention can be carried out as follows:

[0036] (1) Prepare a substrate loaded with a catalyst for preparing gallium nitride nanowires by plasma sputtering (for example, a gold film can be sputtered on a silicon wafer);

[0037] (2) At room temperature, mix elemental gallium, gallium oxide, and elemental carbon, grind them into powder, put them in a crystal boat, and put them in a vacuum tube furnace. Placed in the downstream of the mixture powder, vacuumize to remove the air in the vacuum tube furnace tube, then feed nitrogen until the pressure in the vacuum tube furnace tube is normal pressure; then under normal pressure, continuously feed nitrogen and ammonia, wherein , nitrogen is used as the carrier gas, ammonia is used as the reaction gas, the temperature is continuously raised to the required temperature during the process, and after the reaction is completed, the temperature is naturally...

Embodiment 1

[0052] (1) A gold film with a thickness of 10nm is sputtered on a 10mm×10mm silicon wafer by plasma sputtering;

[0053] (2) At room temperature (generally 10-40°C), mix 2g of metal elemental gallium, 2g of gallium oxide and 0.5g of carbon powder, grind to form a mixture powder, then put the mixture powder in a crystal boat, and place it in a vacuum tube The middle position of the furnace; the aforementioned silicon chip with the gold film is placed downstream of the mixture powder, vacuumed to remove the air in the tube of the vacuum tube furnace, and then nitrogen gas is introduced until the pressure in the tube of the vacuum tube furnace is normal pressure; then Under the condition of normal pressure, nitrogen and ammonia are fed continuously. Among them, nitrogen is used as carrier gas with a flow rate of 40 sccm, and ammonia gas is used as a reaction gas with a flow rate of 80 sccm. During this process, the temperature is continuously raised to 960°C, and the temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com