A kind of copper base solder and preparation method thereof

A copper-based brazing material and blank technology, which is used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as difficulty in adapting to prefabricated precision brazing, weakening of joint mechanical properties, and limiting the application range of brazing filler metals. Inexpensive, Antioxidant Enhancement, Wetting and Gap Filling Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the copper-based solder of the present embodiment may further comprise the steps:

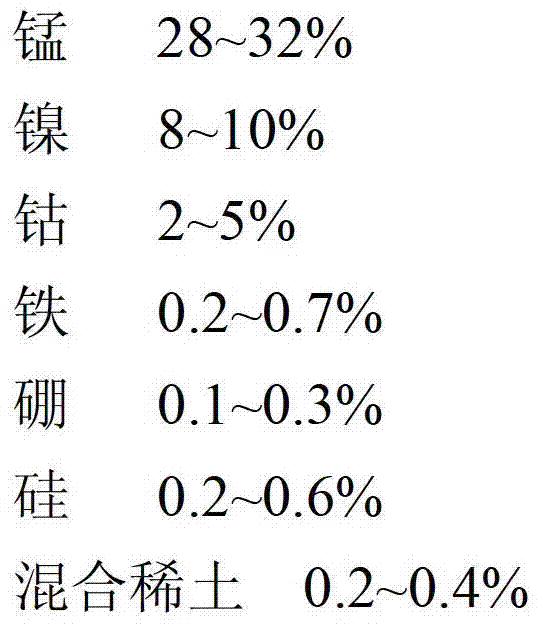

[0028] (1) Ingredients: Copper, manganese, nickel, cobalt, silicon, copper-iron master alloy, copper-boron master alloy, copper-mixed rare earth master alloy are used as raw materials, and the mass percentage of iron in the copper-iron master alloy is 4.95%, and the balance is copper; the mass percentage of boron in the copper-boron master alloy is 4.95%, and the balance is copper; the mass percentage of the misch metal in the copper-boron master alloy is 5.00%, The balance is copper; the mixed rare earth is composed of cerium and lanthanum in any proportion.

[0029] Prepare the charge according to the mass percentage of the following elements:

[0030]

[0031] The balance is copper;

[0032] (2) Melting and casting: put the prepared charge into the corundum crucible in order of manganese, copper, nickel, cobalt, silicon, copper-boron master alloy, copper...

Embodiment 2

[0036] The preparation method of the copper-based solder of the present embodiment may further comprise the steps:

[0037] (1) Ingredients: Copper, manganese, nickel, cobalt, silicon, copper-iron master alloy, copper-boron master alloy, copper-mixed rare earth master alloy are used as raw materials, the mass percentage of iron in the copper-iron master alloy is 5.00%, and the balance is copper; the mass percentage of boron in the copper-boron master alloy is 5.00%, and the balance is copper; is copper; the mixed rare earth is composed of cerium and lanthanum in any proportion.

[0038] Prepare the charge according to the mass percentage of the following elements:

[0039]

[0040] The balance is copper;

[0041] (2) Melting and casting: put the prepared charge into the corundum crucible in order of manganese, copper, nickel, cobalt, silicon, copper-boron master alloy, copper-mixed rare earth master alloy, copper-iron master alloy, and use medium frequency induction melti...

Embodiment 3

[0045] The preparation method of the copper-based solder of the present embodiment may further comprise the steps:

[0046] (1) Ingredients: Copper, manganese, nickel, cobalt, silicon, copper-iron master alloy, copper-boron master alloy, copper-mixed rare earth master alloy are used as raw materials, and the mass percentage of iron in the copper-iron master alloy is is 5.00%, and the balance is copper; the mass percentage of boron in the copper-boron master alloy is 5.00%, and the balance is copper; is copper; the mixed rare earth is composed of cerium and lanthanum in any proportion.

[0047] Prepare the charge according to the mass percentage of the following elements:

[0048]

[0049]

[0050] The balance is copper;

[0051] (2) Melting and casting: put the prepared charge into the corundum crucible in order of manganese, copper, nickel, cobalt, silicon, copper-boron master alloy, copper-mixed rare earth master alloy, copper-iron master alloy, and use medium freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com