High speed rotating machinery axle laser cladding repair alloy powder and repair method

A high-speed rotation and laser cladding technology, applied in laser welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problems of poor wear resistance, easy peeling, large heat input, etc., and achieve good corrosion resistance , Enhanced corrosion resistance, stable operation of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: A laser cladding repair alloy powder for high-speed rotating mechanical shafts, calculated by weight percentage, prepared from the following raw material powders: C 0.13%, Cr 15%, Si 1.3%, Ni 5%, P 0.025% , Fe 78.545%. The alloy powder is prepared by a gas atomization method.

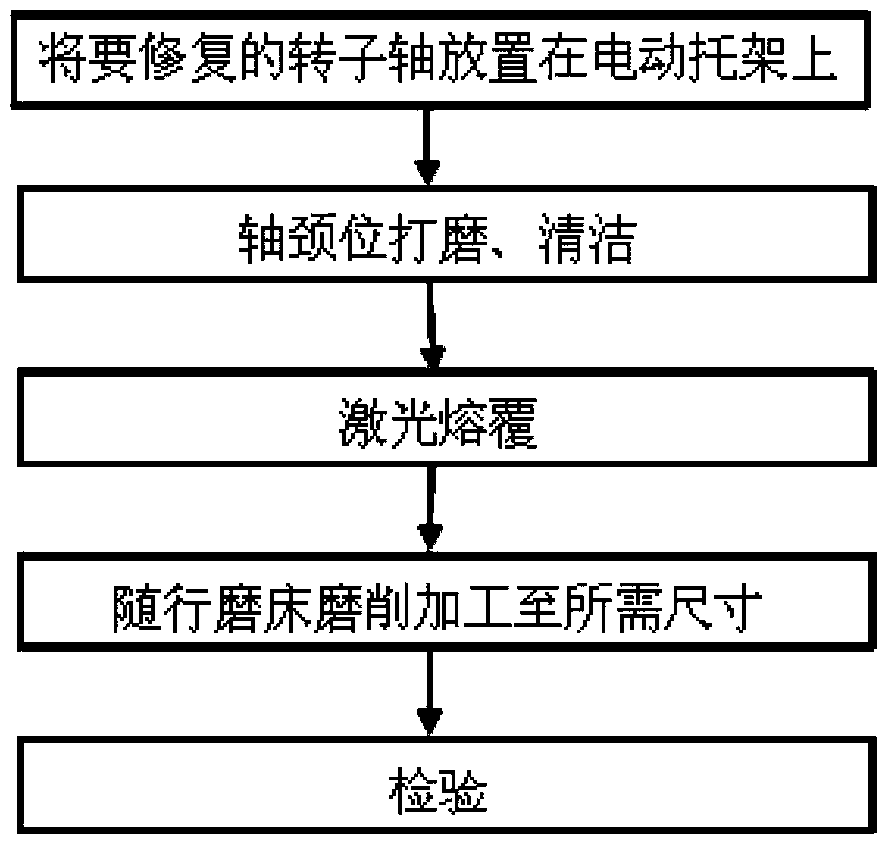

[0037] A laser cladding repair method for a high-speed rotating mechanical shaft, comprising the following steps (such as figure 1 shown):

[0038] A. Place the high-speed rotating mechanical shaft to be processed on the electric bracket that matches its weight and size;

[0039] B. Use sandpaper or a grinder to smooth the scratches on the journal of the high-speed rotating mechanical shaft; if there are cracks or cracks in the journal, use a portable portable grinder for grinding until there are no cracks or cracks;

[0040] C. Use a rag dipped in alcohol to wipe the journal position clean and use the above-mentioned laser cladding of the high-speed rotating mechanical shaft to rep...

Embodiment 2

[0043] Example 2: A laser cladding repair alloy powder for high-speed rotating mechanical shafts, calculated by weight percentage, prepared from the following raw material powders: C 0.13%, Cr 17%, Si 1.3%, Ni 4%, P 0.02% , Fe 77.55%. The alloy powder is prepared by a gas atomization method.

[0044] A laser cladding repair method for a high-speed rotating mechanical shaft, comprising the following steps (such as figure 1 shown):

[0045] A. Place the high-speed rotating mechanical shaft to be processed on the electric bracket that matches its weight and size;

[0046] B. Use sandpaper or a grinder to smooth the scratches on the journal of the high-speed rotating mechanical shaft; if there are cracks or cracks in the journal, use a portable portable grinder for grinding until there are no cracks or cracks;

[0047] C. Wipe the journal position clean and use the above-mentioned laser cladding of the high-speed rotating mechanical shaft to repair the alloy powder, perform las...

Embodiment 3

[0050] Example 3: A laser cladding repair alloy powder for high-speed rotating mechanical shafts, calculated by weight percentage, prepared from the following raw material powders: C 0.13%, Cr 13%, Si 1.3%, Ni 6%, P 0.01% , Fe 79.56%. The alloy powder is prepared by a gas atomization method.

[0051] A laser cladding repair method for a high-speed rotating mechanical shaft, comprising the following steps (such as figure 1 shown):

[0052] A. Place the high-speed rotating mechanical shaft to be processed on the electric bracket that matches its weight and size;

[0053] B. Use sandpaper or a grinder to smooth the scratches on the journal of the high-speed rotating mechanical shaft; if there are cracks or cracks in the journal, use a portable portable grinder for grinding until there are no cracks or cracks;

[0054] C. For the shaft after the shaft neck has been polished and cleaned, use the above-mentioned laser cladding repair alloy powder of the high-speed rotating mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com