Method for preparing nano titanium dioxide by titaniferous tailings after beneficiating iron

A nano-titanium dioxide and iron beneficiation technology, which is applied in the field of comprehensive utilization of mineral resources, can solve the problems of difficult to achieve monomer dissociation, fine ore embedded particle size, and difficulty in comprehensive recovery of titanium, so as to save the beneficiation process, shorten the process, and expand the The effect of using ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

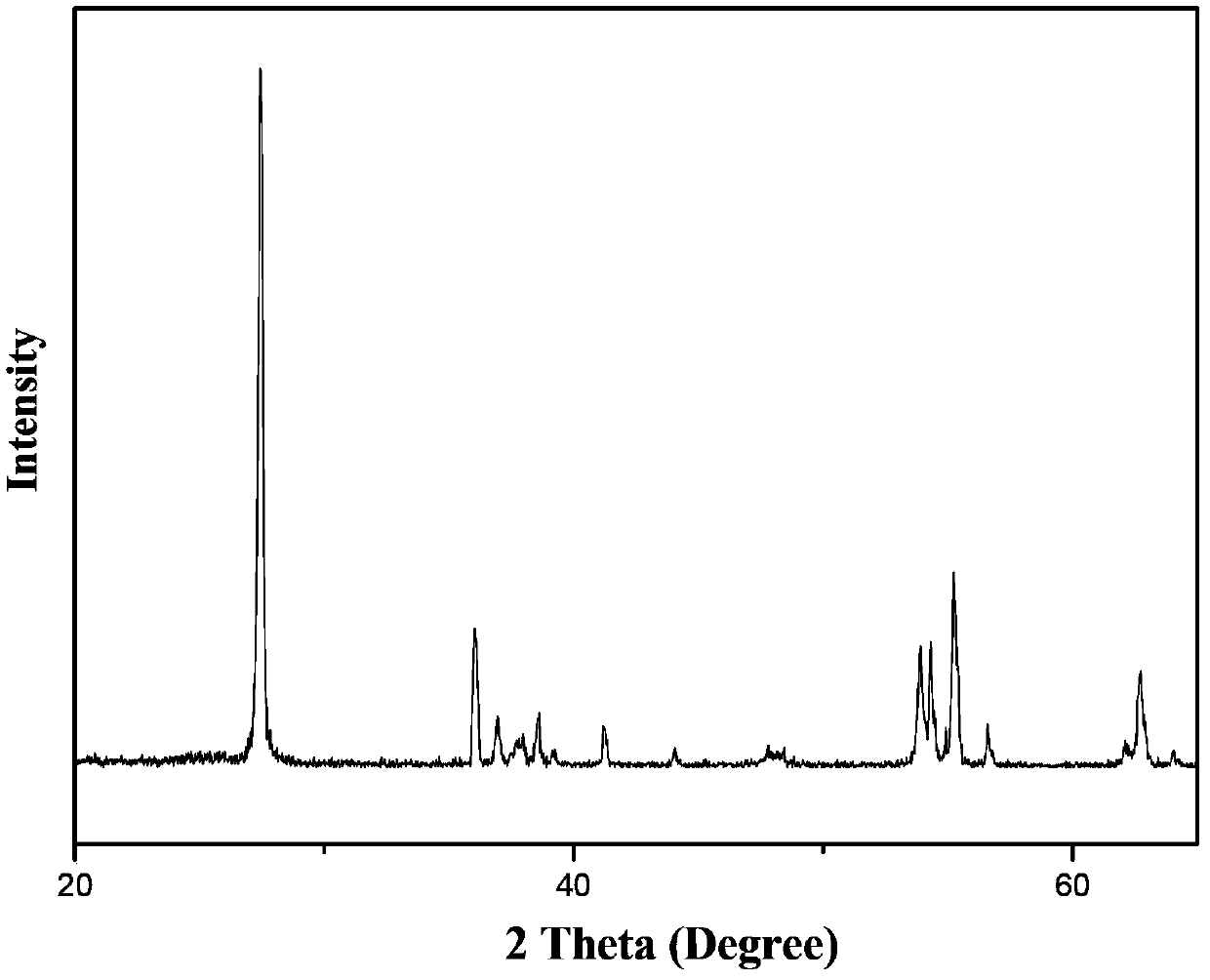

Image

Examples

Embodiment 1

[0020] A method for preparing nano-titanium dioxide from titanium-containing iron dressing tailings, the specific embodiment is that the titanium-containing iron dressing tailings are ground to -200 mesh and not less than 95%, and then mixed with concentrated sulfuric acid with a concentration greater than 70% according to the mass ratio of 5. : 1 ratio, roasting at 280 ° C for 3 hours, so that the titanium metal in it becomes soluble sulfate, then add the concentrated sulfuric acid leaching of 2 times the mass of the titanium-containing iron tailings, and then 5 times the titanium-containing iron tailings After diluting the leaching solution with iron powder containing 5% of the mass of titanium-containing iron tailings, green vitriol crystals are precipitated at 0 ° C, the obtained solution is heated to boiling and hydrolyzed, and the resulting solid is dried and then roasted at 800 ° C for 2 Hour. The resulting product TiO 2 The grade reaches 93.6%, and its particle size i...

Embodiment 2

[0022] A method for preparing nano-titanium dioxide from titanium-containing iron dressing tailings, the specific embodiment is that the titanium-containing iron dressing tailings are ground to -200 mesh and not less than 95%, and then mixed with concentrated sulfuric acid with a concentration greater than 70% according to the mass ratio of 4. : 1 ratio, roasting at 300 ℃ for 3 hours, so that the titanium metal in it becomes soluble sulfate, then add the concentrated sulfuric acid leaching of 2 times the mass of the titanium-containing iron tailings, and then use 10 times the titanium-containing iron tailings. After diluting the leaching solution with iron powder containing 15% of the mass of iron tailings containing titanium, green vitriol crystals were precipitated at 10 ° C, the obtained solution was heated to boiling and hydrolyzed, and the resulting solid was dried and then roasted at 700 ° C. 2 hours. The resulting product TiO 2 The grade reaches 92.3%, and its particle...

Embodiment 3

[0024] A method for preparing nano-titanium dioxide from titanium-containing iron dressing tailings, the specific embodiment is that the titanium-containing iron dressing tailings are ground to -200 mesh and not less than 95%, and then mixed with concentrated sulfuric acid with a concentration greater than 70% according to the mass ratio of 2. : 1 ratio, roasting at 260 ° C for 3 hours, so that the titanium metal in it becomes soluble sulfate, then add the concentrated sulfuric acid leaching of 2 times the mass of the titanium-containing iron tailings, and then 8 times the titanium-containing iron tailings After diluting the leaching solution with iron powder containing 10% of the mass of titanium-containing iron tailings, green vitriol crystals are precipitated at 5 ° C, the obtained solution is heated to boiling and hydrolyzed, and the resulting solid is dried and then roasted at 600 ° C. 2 hours. The resulting product TiO 2 The grade reaches 92.7%, and its particle size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com