A kind of preparation method of triangular section polyacrylonitrile carbon fiber

A polyacrylonitrile, triangular technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of easy fiber breakage, uneven fiber thickness, low product productivity, etc., to improve strength and elongation at break, cross-section Regular shape and less fiber defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

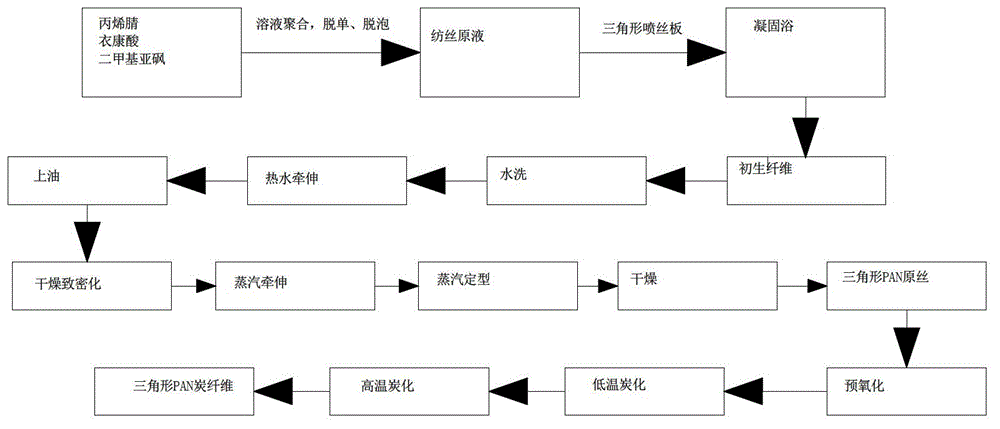

Method used

Image

Examples

Embodiment approach 1

[0023] Put acrylonitrile and itaconic acid into dimethyl sulfoxide solvent for polymerization reaction, the mass ratio of acrylonitrile and itaconic acid is 99.4:0.6, after the polymerization reaction, it undergoes single and defoaming treatment to prepare The dimethyl sulfoxide solution of polyacrylonitrile is used as the spinning stock solution, the concentration of the polyacrylonitrile is 20%, and the dry-jet wet spinning is carried out by a spinneret with an equivalent aperture of 0.1 mm and a hole number of 3000 holes. After the silk stock solution passes through the spinneret and passes through a 3mm air layer, it is introduced into a coagulation bath for molding. The coagulation bath is an aqueous solution of dimethyl sulfoxide, and the concentration of the coagulation bath is 20%. The temperature of the coagulation bath The temperature is 5°C, the draw ratio of the nozzle is 2.0, and the triangular PAN as-spun fibers are obtained;

[0024] After the triangular PAN as-...

Embodiment approach 2

[0027] Put acrylonitrile and itaconic acid into dimethyl sulfoxide solvent for polymerization reaction, the mass ratio of acrylonitrile and itaconic acid is 99.4:0.6, after the polymerization reaction, it undergoes single and defoaming treatment to prepare The dimethyl sulfoxide solution of polyacrylonitrile is used as the spinning stock solution, the concentration of the polyacrylonitrile is 15%, and the molecular weight of the polymer is 180,000; the equivalent pore diameter is 0.1mm, and the number of holes is 3000. The board is subjected to dry jet wet spinning, and the spinning stock solution passes through the spinneret and passes through a 10mm air layer before being introduced into a coagulation bath for molding. The coagulation bath is an aqueous solution of dimethyl sulfoxide, and the concentration of the coagulation bath is is 50%, the temperature of the coagulation bath is 50°C, and the stretch ratio of the nozzle is 0.5 to obtain triangular PAN as-spun fibers;

[...

Embodiment approach 3

[0031] Put acrylonitrile and itaconic acid into dimethyl sulfoxide solvent for polymerization reaction, the mass ratio of acrylonitrile and itaconic acid is 99.4:0.6, after the polymerization reaction, it undergoes single and defoaming treatment to prepare The dimethyl sulfoxide solution of polyacrylonitrile is used as the spinning stock solution, the concentration of the polyacrylonitrile is 25%, the molecular weight of the polymer is 200,000, and the equivalent pore diameter is 0.1mm, and the number of holes is 3000. The board is subjected to dry jet wet spinning, and the spinning stock solution passes through the spinneret and passes through a 20mm air layer, and then it is introduced into a coagulation bath for molding. The coagulation bath is an aqueous solution of dimethyl sulfoxide, and the concentration of the coagulation bath is is 70%, the temperature of the coagulation bath is 75°C, and the stretch ratio of the nozzle is 3.5 to obtain triangular PAN primary fibers; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com