Penetrating bar type aluminum alloy heat insulation section bar and machining method

An aluminum alloy and strip-threading technology, which is applied in windows/doors, building components, buildings, etc., can solve the problems of poor processing effect, affecting product performance, complexity, etc., and achieve reasonable force, good symmetry, and cross-section regular shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

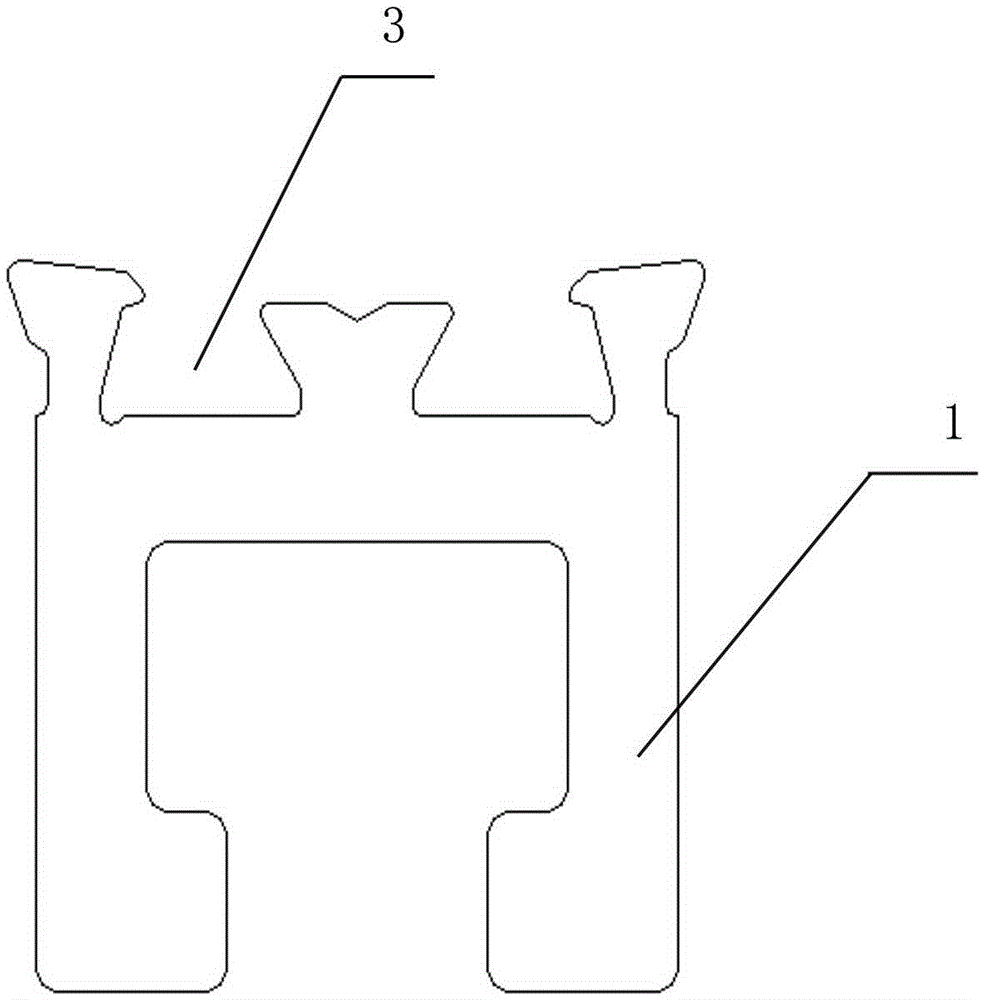

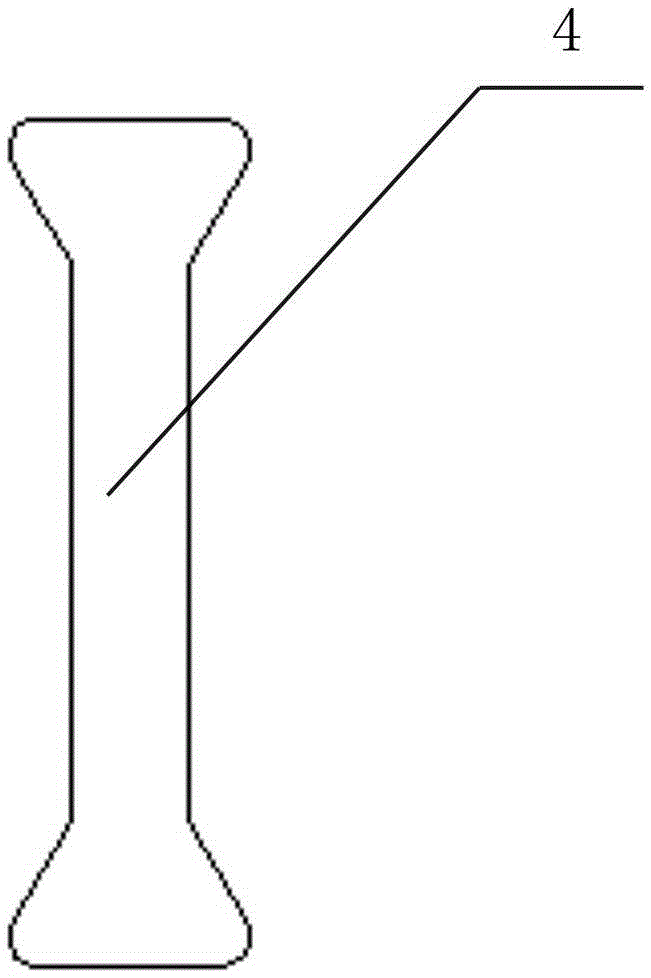

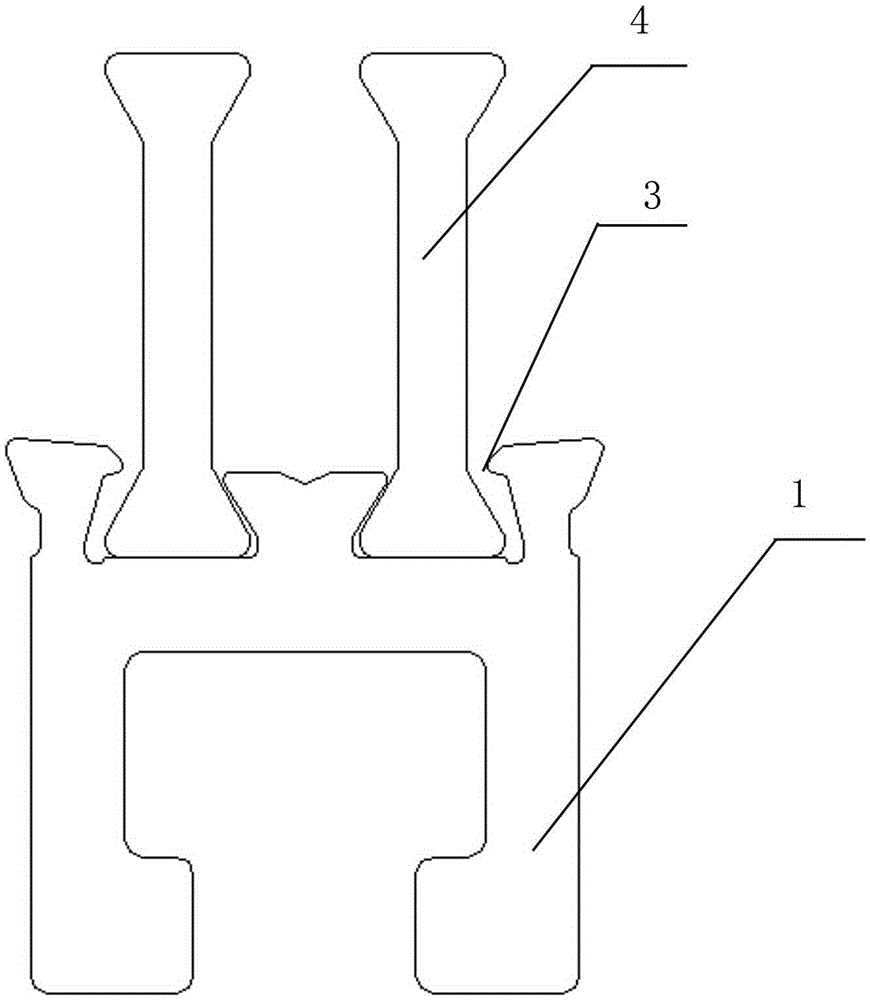

[0022] Embodiment one, in figure 1 , figure 2 , image 3 with Image 6 Among them, the present invention discloses a strip-type aluminum alloy heat-insulating profile, which is characterized in that it includes a profile I1 and a profile II2, and one side of the profile I1 is provided with a number of threading notches I3, and the profile I1 in this embodiment One side of the profile II2 is provided with two threading notches I3, and teeth are provided on the inner wall on both sides of each threading notch I3. The top of the profile II2 is provided with several threading notches II. The profile of this embodiment The top of Ⅱ2 is provided with two threading notches II, teeth are provided on the inner walls of each threading notch II, and heat insulation is provided between each threading notch I3 and each threading notch II Strip 4, profile Ⅰ1 passes through the two ends of the heat insulation strip 4 and respectively penetrates into the strip-threading notch Ⅰ3 and the s...

Embodiment 2

[0023] Embodiment two, in figure 1 , figure 2 , image 3 with Figure 5 , the present invention also discloses a strip-threaded aluminum alloy heat-insulating profile, which is characterized in that it includes profile I1 and profile II2, and one side of the profile I1 is provided with several strip-threading notches I3, and the profile of this embodiment One side of I1 is provided with two threading notches I3, and teeth are provided on the inner wall on both sides of each threading notch I3, and the top of the profile II2 is provided with several threading notches II. The top of the profile Ⅱ2 is provided with two threading notches Ⅱ, teeth are provided on the inner wall of each threading notch Ⅱ, and there is a spacer between each threading notch Ⅰ3 and each threading notch Ⅱ. The heat strip 4 and the profile I1 pass through the two ends of the heat insulation strip 4 respectively into the strip-threading notch I3 and the strip-threading notch II, and then roll and comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com