Sea island type composite fiber and its manufacturing method and application

A technology of composite fibers and manufacturing methods, applied in fiber processing, conjugated synthetic polymer artificial filaments, textiles and papermaking, etc., can solve problems such as difficult disposal or recycling, adverse environmental effects, etc., and achieve easy post-processing and environmental friendliness , Strong effect of transplantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 〖Example 1〗Preparation of PLA / PP island-in-the-sea composite fiber and its subsequent superfine products

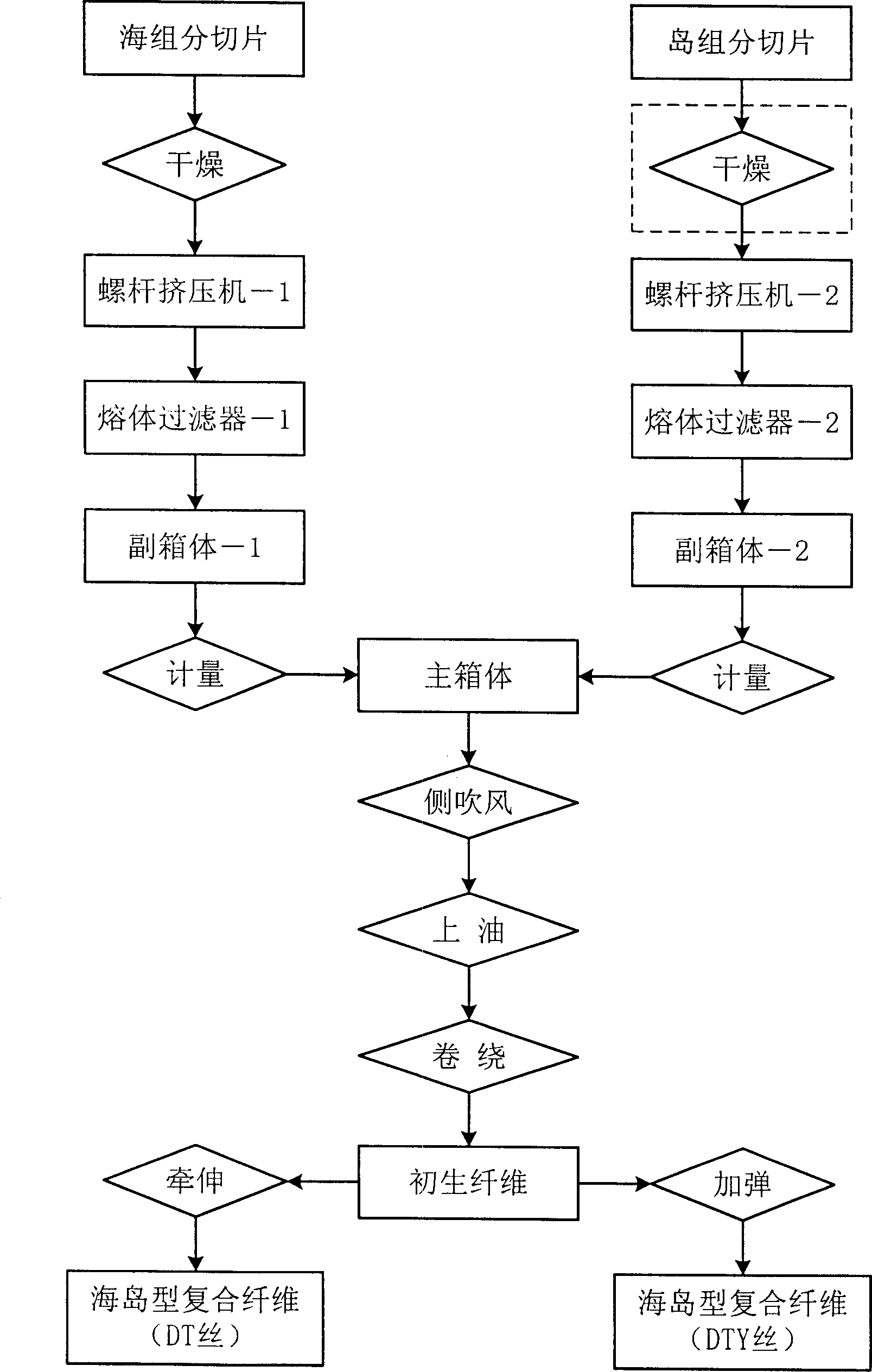

[0027] As shown in the flow chart in Figure 1, PLA slices are used as the sea component and PP slices are used as the island component. After the moisture content of the slices is less than 300ppm, they are spun on the ABE composite spinning machine, and the sea component slices and the island component slices are heated, extruded, and melted through the respective screw extruder-1 and screw extruder-2 , and then filtered through melt filter-1 and melt filter-2 to become spinnable melt, which enters the sub-box-1 and sub-box-2 respectively, and enters the main spinning box after each metering The two melts are mixed inside the main box, and the tow is sprayed from the spinneret, cooled and formed by side blowing, and then processed through two processes of oiling and winding to obtain the primary fiber, that is, the undrawn filament ( UDY). The main process condi...

Embodiment 2

[0031] 〖Example 2〗Preparation of PLA / PA6 island-in-the-sea composite fiber and its subsequent superfine products

[0032] Use PLA slices as the sea component and PA6 slices as the island component. The weight ratio of the two is 1:1. Dry the two slices separately with drying equipment. The drying temperature is 80-120°C, and the moisture content of the slices is less than 300ppm. Afterwards, on the ABE composite spinning machine, prepare UDY silk with the process similar to that in 〖Example 1〗, the main process conditions are as follows:

[0033]

components

Each zone of the screw extruder

temperature(℃)

Metering pumps

temperature

(℃)

Metering pumps

Rotating speed

(rpm)

main box

temperature

(℃)

components

temperature

(℃)

spinning

speed

(m / min)

one

Area

two

Area

three

Area

Four ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com