Aluminum profile first-spraying and last-assembling process

An aluminum profile and threading technology, which is applied to coatings, devices for coating liquid on surfaces, and pretreatment surfaces, etc., can solve the problem of difficulty in effectively guaranteeing the quality of the final product, achieve beautiful colors, reduce equipment costs, and reduce cross-sections. shapely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

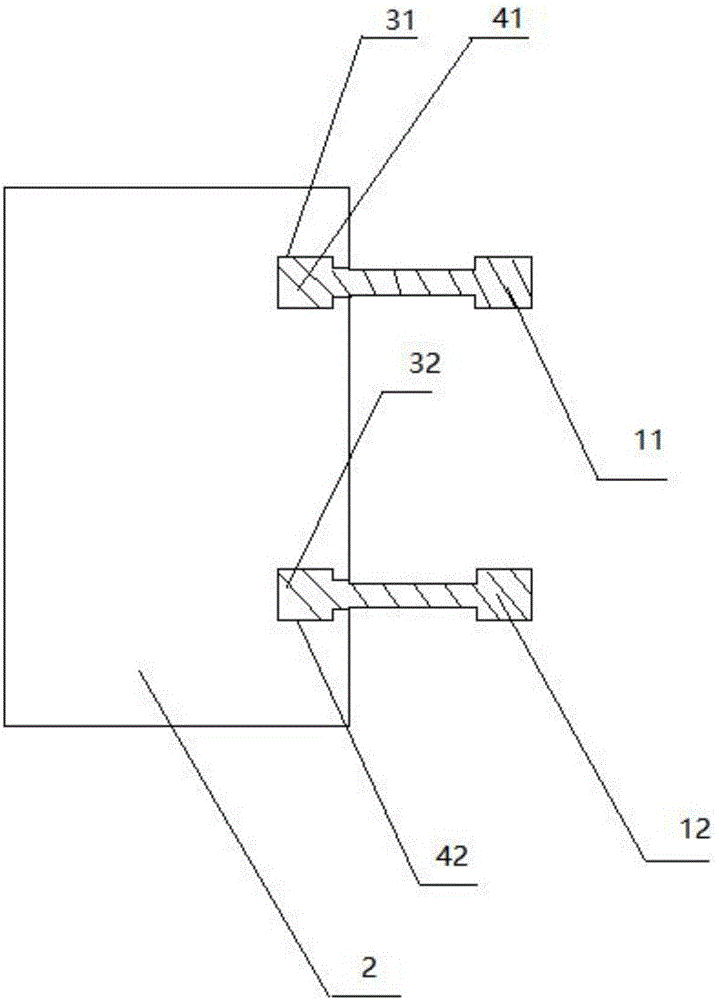

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0026] An aluminum profile is first sprayed and then threaded. The process steps are as follows:

[0027] a. cutting: cutting the unsprayed aluminum alloy raw materials according to the proportion to form aluminum profiles;

[0028] b. Aluminum profile surface cleaning treatment: After grinding the aluminum alloy surface and rinsing with water; put in the mixed acid solution for 5-7 minutes, take it out and rinse with water;

[0029] c. Passivation treatment: After rinsing the aluminum alloy with pure water, place the aluminum alloy in the passivation solution. After 6-12 minutes, a colored passivation film is formed on the surface of the aluminum alloy;

[0030] d. Drying: place the passivated aluminum profile in a drying oven to dry;

[0031] e. Electrostatic spraying: put the punch mold in the aluminum profile, and then send it into the electrostatic spraying mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com