Zinc-induced crack-resistant steel sheet and manufacturing method thereof

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve the problems of zinc-induced crack resistance and non-involvement of steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

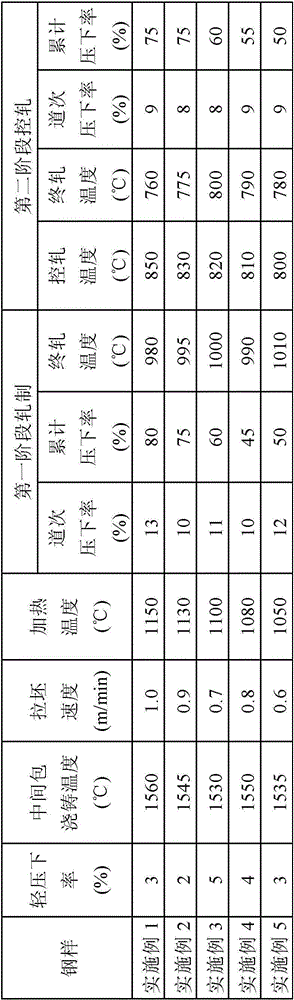

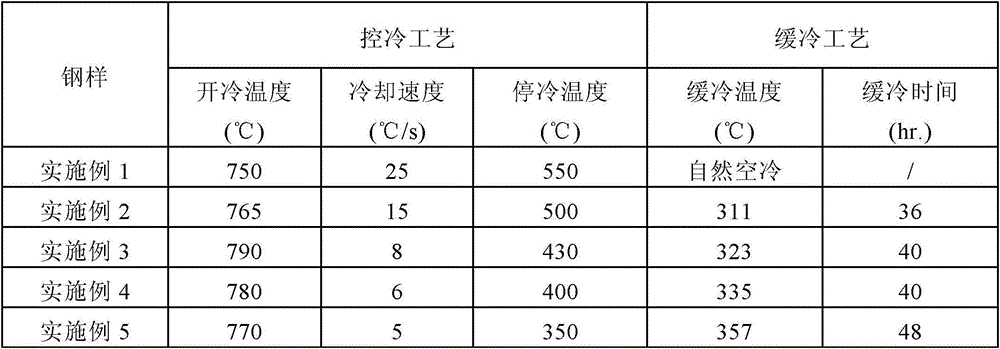

[0069] Refer to Table 1 for the composition of the steel in the embodiment of the present invention, and refer to Table 2 and Table 3 for the manufacturing process of the steel in the embodiment. Table 4 shows the properties of the steel in the embodiment of the present invention.

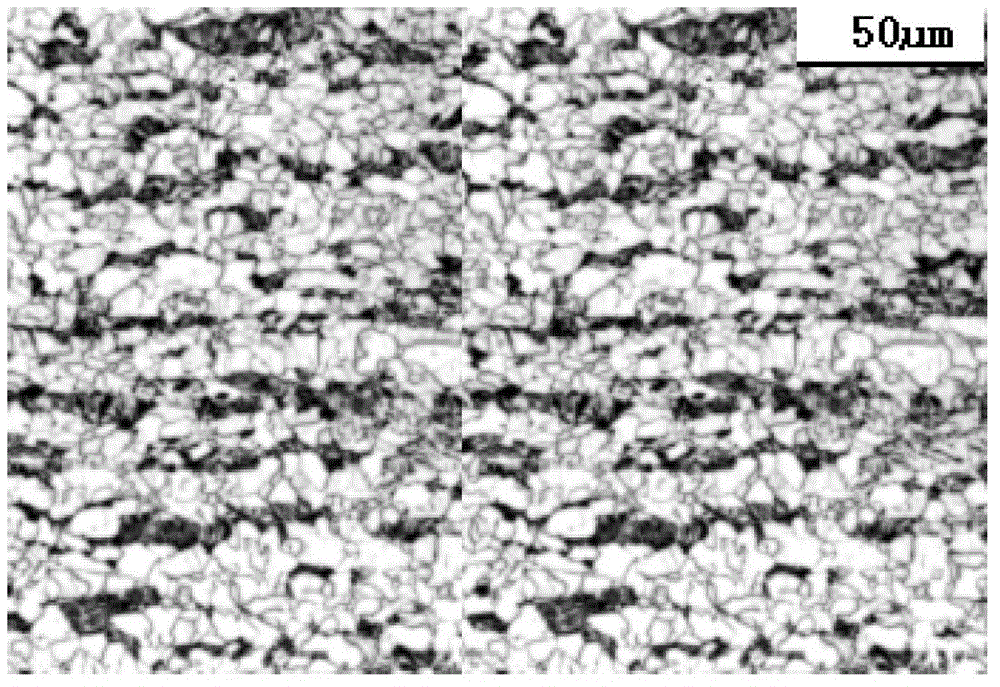

[0070] Such as figure 1 As shown, the microstructure of the finished steel plate of the present invention is ferrite + finely dispersed and uniformly distributed bainite crystal clusters, the average grain size is controlled below 10 μm, and the microstructure of the welded heat-affected zone is fine and uniform ferrite body + a small amount of pearlite.

[0071] The present invention adopts the combination design of alloy elements and strict control of residual B elements in the steel, and is matched with a suitable TMCP process. While ensuring the excellent mechanical pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com