Zinc-induced-crack-resistant steel plate and manufacturing method thereof

A technology for steel plates and cracks, applied in the field of anti-zinc cracking steel plates and their manufacture, can solve the problems of no zinc-induced cracking of steel plates and no

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

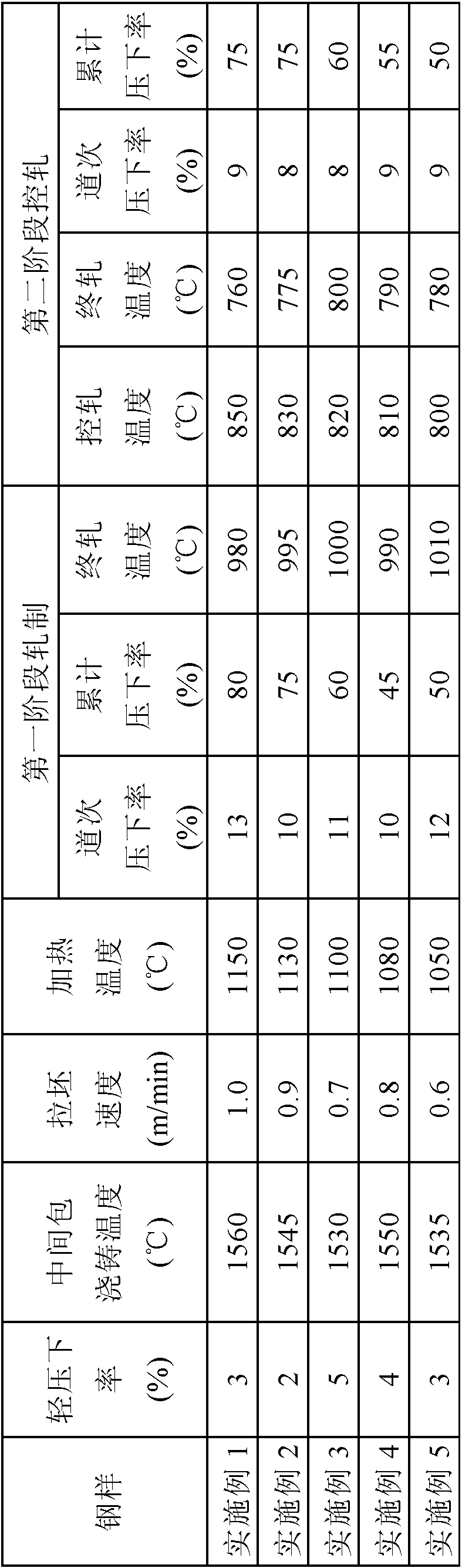

[0069] Refer to Table 1 for the composition of the steel in the embodiment of the present invention, and refer to Table 2 and Table 3 for the manufacturing process of the steel in the embodiment. Table 4 shows the properties of the steel in the embodiment of the present invention.

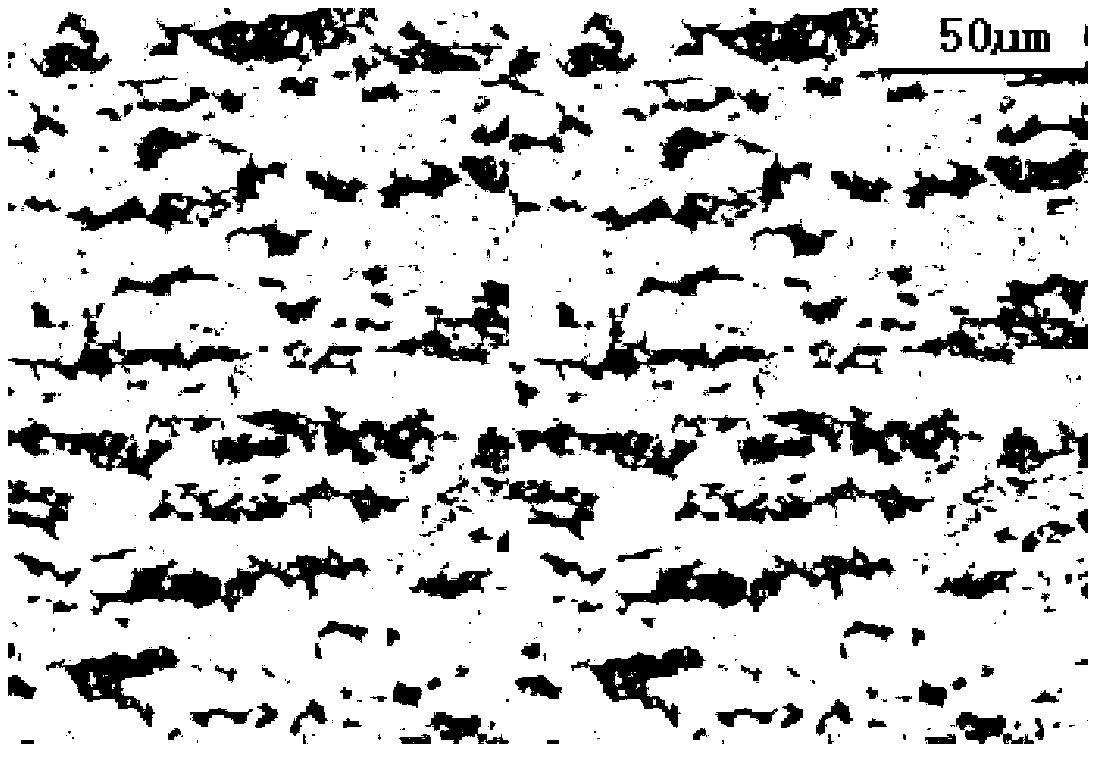

[0070] Such as figure 1 As shown, the microstructure of the finished steel plate of the present invention is ferrite + finely dispersed and uniformly distributed bainite crystal clusters, the average grain size is controlled below 10 μm, and the microstructure of the welded heat-affected zone is fine and uniform ferrite body + a small amount of pearlite.

[0071] The present invention adopts the combination design of alloy elements and strict control of residual B elements in the steel, and is matched with a suitable TMCP process. While ensuring the excellent mechanical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com