Phosphate based red phosphor, preparation method and application thereof

A technology of red fluorescent powder and phosphate, which is applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of easily corroded LED chips, complex circuit design, and unsatisfactory requirements, and achieve good output wavelength matching, Ease of handling and rich raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

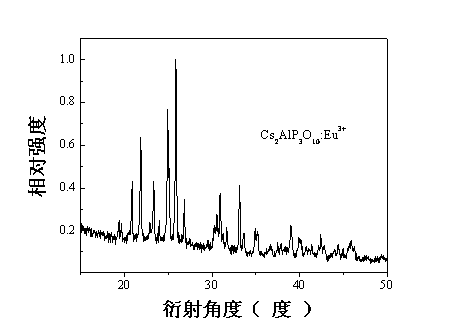

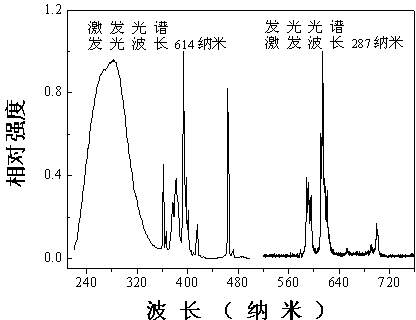

[0033] Preparation of Cs 1.9 Eu 0.1 AlP 3 o 10

[0034] According to the chemical formula Cs 1.9 Eu 0.1 AlP 3 o 10 The stoichiometric ratio of each element in the formula, the raw materials were weighed respectively:

[0035] Cesium Carbonate Cs 2 CO 3 : 1.55 g,

[0036] Europium oxide Eu 2 o 3 : 0.09 g,

[0037] Alumina Al 2 o 3 : 0.26 g,

[0038] Ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 1.73 grams;

[0039] After grinding and mixing the raw materials in an agate mortar, pre-sintering is carried out in an air atmosphere. The pre-sintering temperature is 350°C, and the sintering time is 5 hours. After cooling to room temperature, the samples are taken out; the raw materials for the first sintering are fully Mix and grind evenly, carry out the second sintering in the air atmosphere, the sintering temperature is 500°C, the calcination time is 8 hours, cool to room temperature, take out the sample; finally it is fully ground again and put into the muffle ...

Embodiment 2

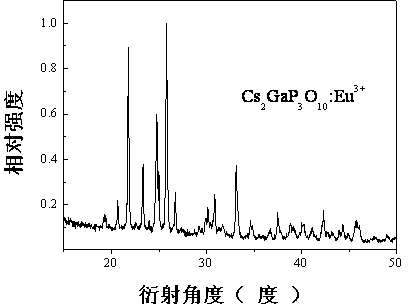

[0043] Preparation of Cs 1.8 Eu 0.2 GaP 3 o 10

[0044] According to chemical formula Cs 1.8 Eu 0.2 GaP 3 o 10 , respectively weigh cesium carbonate Cs 2 CO 3 : 1.47 g, europium oxide Eu 2 o 3 : 0.18 g, gallium oxide Ga 2 o 3 : 0.47 g, ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 1.73 grams, after grinding and mixing in an agate mortar, select the air atmosphere for pre-sintering, the pre-sintering temperature is 400 ° C, the sintering time is 3 hours, then cool to room temperature, take out the sample; the raw material for the first sintering is again Thoroughly mix and grind evenly, carry out the second sintering in the air atmosphere, the sintering temperature is 450°C, the calcination time is 8 hours, cool to room temperature, take out the sample; finally it is fully ground again and placed in the muffle furnace, in the air It is calcined under atmosphere, the calcining temperature is 800° C., and the calcining time is 12 hours. After cooling, the powdery ...

Embodiment 3

[0049] Preparation of Cs 1.999 Eu 0.001 AlP 3 o 10

[0050] According to the chemical formula Cs 1.999 Eu 0.001 AlP 3 o 10 The stoichiometric ratio of each element in , respectively weigh cesium carbonate Cs 2 CO 3 : 6.51 g, europium oxide Eu 2 o 3 : 0.004 g, aluminum oxide Al 2 o 3 : 1.02 g, ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 1.73 g, after grinding and mixing in an agate mortar, select the air atmosphere for pre-sintering, the pre-sintering temperature is 450 ° C, the sintering time is 8 hours, cool to room temperature, take out the sample; the raw material for the first sintering is again Thoroughly mix and grind evenly, carry out the second sintering in the air atmosphere, the sintering temperature is 500 ° C, the calcination time is 8 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in the muffle furnace, in the Calcining under air atmosphere, the calcining temperature is 800°C, the calcining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com