Magnesium oxide whisker/biodegradable polyester composite material and its preparation method and application thereof

A technology for biodegrading polyester and magnesium oxide whiskers, which is applied in the fields of medical science and prostheses, can solve the problems of rapid degradation speed and strength attenuation, weak interfacial bonding force, slow degradation speed, etc., and achieve the reduction of non-infectious Sexual inflammatory response, improving mechanical strength and modulus, improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: the preparation of magnesium oxide whisker

[0057] Step (1): Na with a concentration of 0.5mol / L 2 CO 3 Under the condition of stirring at 800rpm, the concentration of 0.5mol / L MgCl was added dropwise at a rate of 2mL / min. 2 solution; after the dropwise addition, continue to stir for 15 minutes, let stand and age for 24 hours, filter with suction and wash with distilled water 4 times, and dry in a vacuum oven at 80°C to obtain magnesium carbonate whiskers;

[0058] Step (2): Put the magnesium carbonate whiskers obtained in step (1) into a muffle furnace for calcination. The calcination conditions are as follows: from room temperature to 800°C at a rate of 2°C / min and keep it warm for 2 hours, and when it is cooled to 450°C Take out the crucible and quickly put it in a desiccator to cool down to room temperature to obtain magnesium oxide whiskers (MgO whiskers).

Embodiment 2

[0059] Embodiment 2: the preparation of magnesium oxide whisker

[0060] Step (1): Na with a concentration of 0.5mol / L 2 CO 3 Under the condition of stirring at 1200rpm, the concentration of 0.5mol / L MgCl was added dropwise at a rate of 3mL / min. 2 solution; after the dropwise addition, continue to stir for 30 minutes, let stand and age for 24 hours, filter and wash with distilled water 5 times, and dry in a vacuum oven at 80°C to obtain magnesium carbonate whiskers;

[0061] Step (2): Put the magnesium carbonate whiskers obtained in step (1) into a muffle furnace for calcination. The calcination conditions are as follows: from room temperature to 380°C at a rate of 3°C / min and keep warm for 30min, then at 5°C / min Raise the rate to 700°C and keep it warm for 2 hours. When it cools down to 400°C, take out the crucible and quickly put it in a desiccator to cool to room temperature to obtain magnesium oxide whiskers (MgO whiskers).

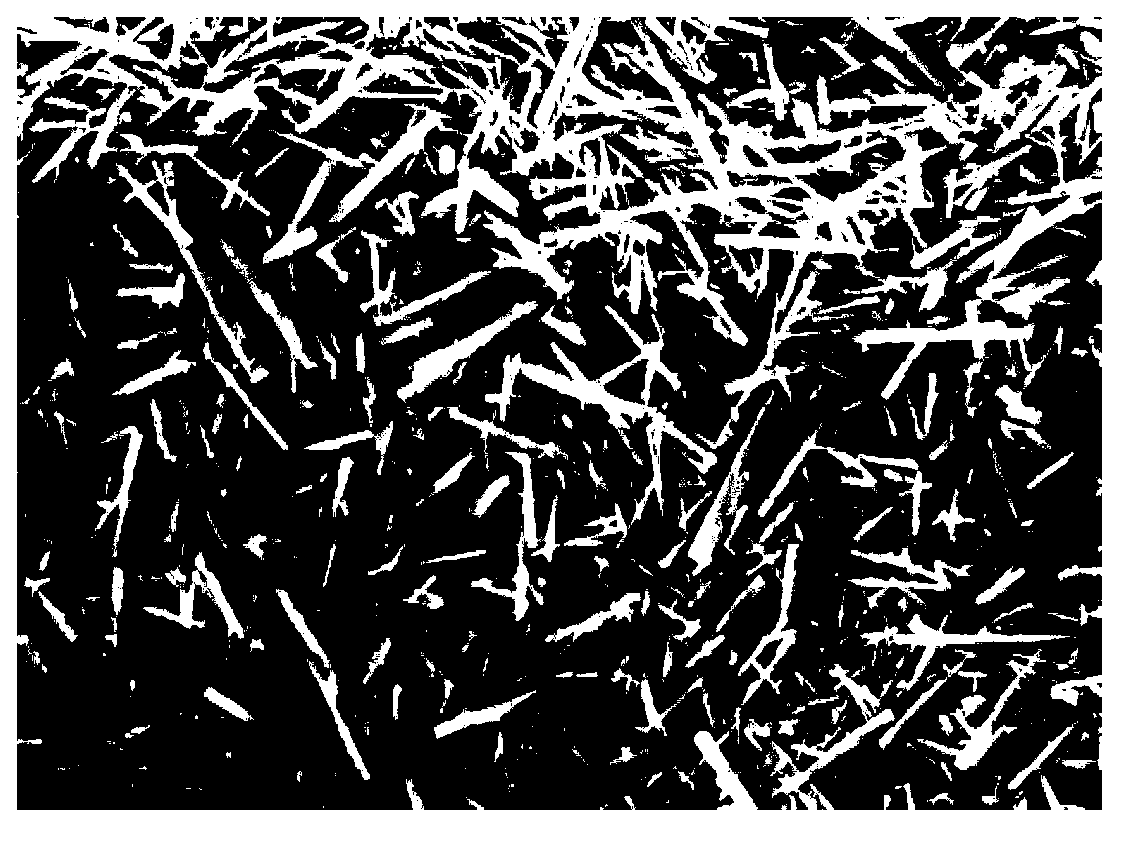

[0062] The morphology of the as-prepared mag...

Embodiment 3

[0063] Embodiment 3: the magnesium oxide whisker of surface grafting polylactic acid is prepared by direct dehydration polycondensation method

[0064] Step (1): In a three-necked flask, disperse 10 g of vacuum-dried MgO whiskers (prepared in Example 2) in 200 ml of toluene, add 1 g of catalyst zinc oxide under the condition of stirring at 600 rpm, and then slowly Add 200g of L-lactic acid, after the dropwise addition, azeotropic dehydration reaction at 110°C for 12h;

[0065] Step (2): After the above reaction is completed, centrifuge the product at 800rpm, remove the supernatant, and take the lower layer of solid product, then add chloroform to dissolve, centrifuge, filter, and wash the solid product for more than 5 times to remove the lactic acid adsorbed on the surface of the solid product Monomers and polylactic acid oligomers; finally, the solid product was collected by high-speed centrifugation and dried in vacuum to obtain MgO whiskers (g-MgO whiskers) grafted with pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com