A strontium-containing cast zinc alloy and its preparation method

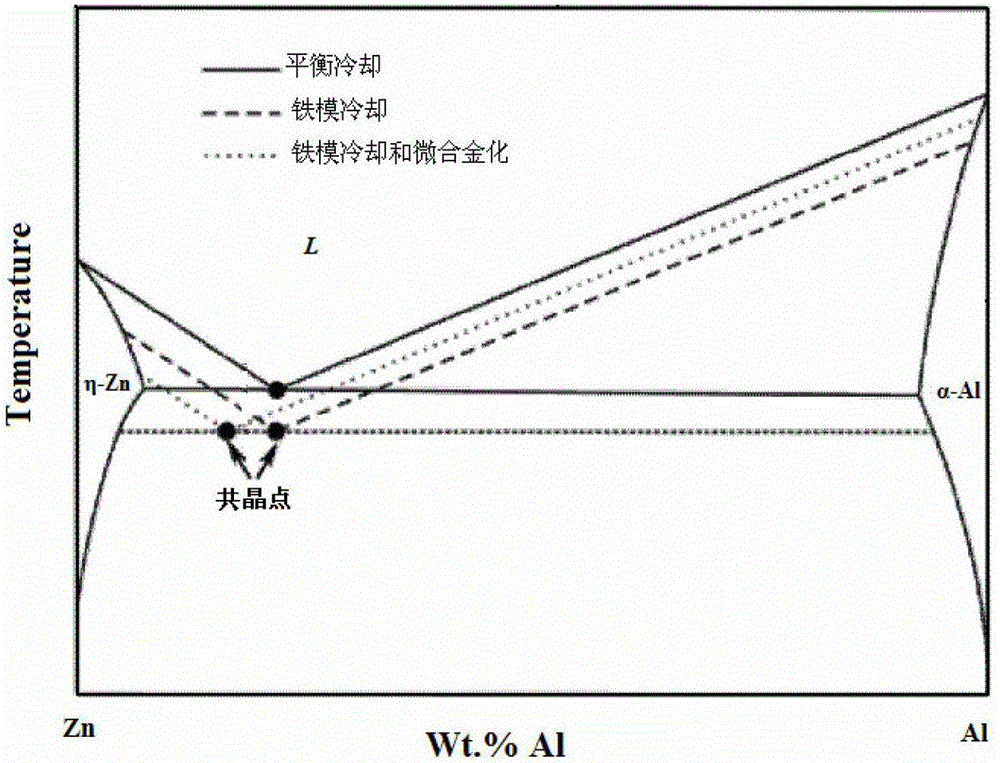

A zinc alloy and master alloy technology, which is applied to the field of strontium-containing cast zinc alloy and its preparation, can solve the problems of large lattice mismatch, which is not conducive to effective nucleation core, etc., and achieves refining as-cast dendrites and improving alloys. The effect of comprehensive mechanical properties and elongation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

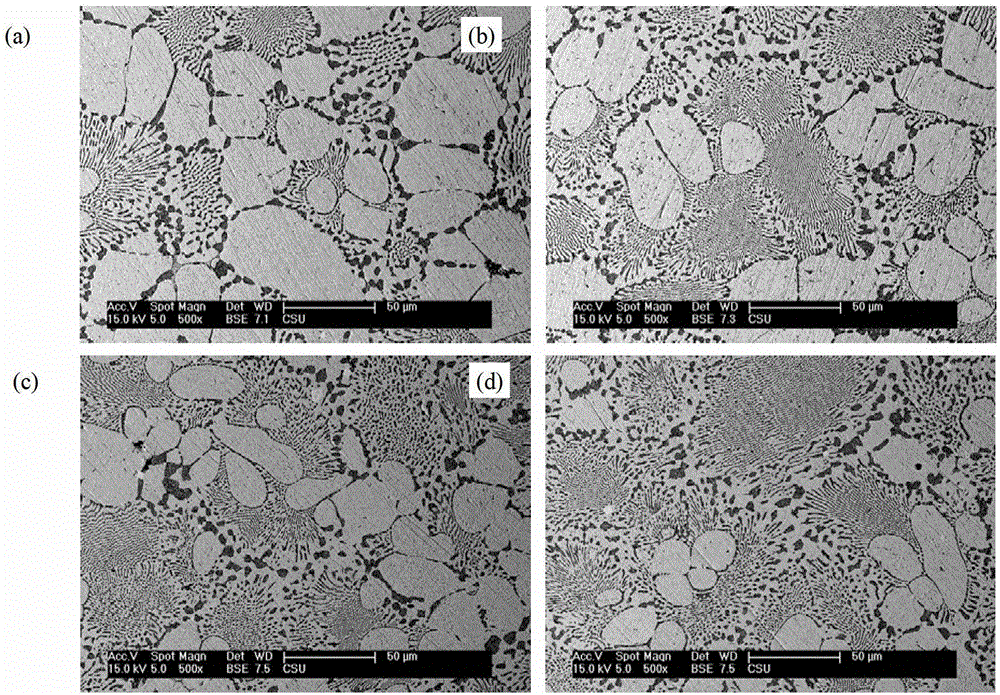

[0038] Add Sr at 0.03% of the total mass of the zinc alloy, use pure Zn ingots with a purity greater than 99.97%, Zn-5%Al master alloys, Al-10%Sr master alloys, and Al-11.07%Mg master alloys as raw materials. -Al master alloy is put into the smelting furnace, the temperature is raised to 550°C, and then Al-Mg master alloy, pure Zn ingot and Al-Sr master alloy are added in turn, and the temperature is raised to 650-660°C. After the metal is completely melted, stir evenly, With 0.3% NH of the total weight of ingredients 4 The Cl refining agent refines the alloy liquid, removes slag, cools down to 500-550°C, and after standing for 10 minutes, removes slag and casts. The composition and weight percentage of the alloy are: 3.5%Al, 0.039%Mg, 0.03%Sr, and the rest is Zn. The alloy structure after adding Sr element is as follows: figure 1 As shown in (b), compared with Comparative Example 1, the size of white dendrites is reduced. Its mechanical properties are the same as the alloy...

Embodiment 2

[0040] Add Sr at 0.06% of the total mass of the zinc alloy, use pure Zn ingots with a purity greater than 99.97%, Zn-5%Al master alloys, Al-10%Sr master alloys, and Al-11.07%Mg master alloys as raw materials. -Al master alloy is put into the smelting furnace, the temperature is raised to 550°C, and then Al-Mg master alloy, pure Zn ingot and Al-Sr master alloy are added in turn, and the temperature is raised to 650-660°C. After the metal is completely melted, stir evenly, With 0.3% NH of the total weight of ingredients 4 The Cl refining agent refines the alloy liquid, removes slag, cools down to 500-550°C, and after standing for 10 minutes, removes slag and casts. The composition and weight percentage of the alloy are: 3.8% Al, 0.079% Mg, 0.06% Sr, and the rest is Zn. The alloy structure after adding Sr element is as follows: figure 1 As shown in (c), the white dendrites are significantly reduced in size and distributed in the matrix in a nearly equiaxed shape. Its mechanica...

Embodiment 3

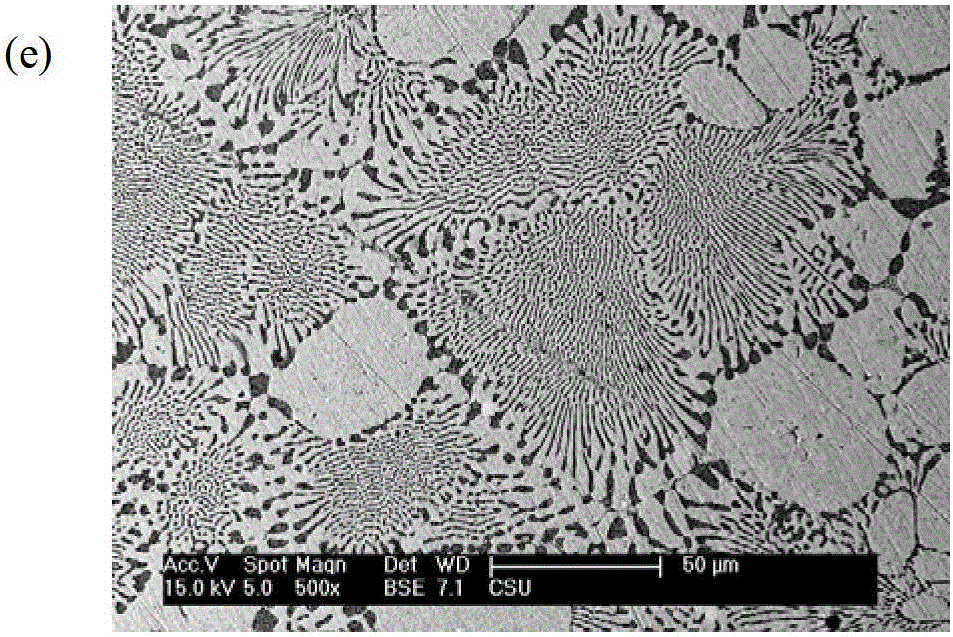

[0042] Add Sr at 0.10% of the total mass of the zinc alloy, use pure Zn ingots with a purity greater than 99.97%, Zn-5%Al master alloys, Al-10%Sr master alloys, and Al-11.07%Mg master alloys as raw materials. -Al master alloy is put into the smelting furnace, the temperature is raised to 550°C, and then Al-Mg master alloy, pure Zn ingot and Al-Sr master alloy are added in turn, and the temperature is raised to 650-660°C. After the metal is completely melted, stir evenly, With 0.3% NH of the total weight of ingredients 4 The Cl refining agent refines the alloy liquid, removes slag, cools down to 500-550°C, and after standing for 10 minutes, removes slag and casts. The composition and weight percentage of the alloy are: 4.3%Al, 0.049%Mg, 0.10%Sr, and the rest is Zn. The alloy structure after adding Sr element is as follows: figure 1 As shown in (d), the size of the white phase is further reduced, and the energy spectrum of the second Sr-containing phase is as follows image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com