Low-temperature co-fired ceramic baseplate material

A low-temperature co-fired ceramic and ceramic substrate technology, which is applied in the field of electronic substrate materials, can solve the problems of high sintering temperature and achieve excellent dielectric properties, cost reduction, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of the low-temperature co-fired ceramic substrate material provided by the present invention comprises the following steps:

[0014] Step 1 Combine ZnO with H 3 BO 3 Mix evenly in a dry environment;

[0015] Step 2: Heat the mixture at room temperature at 1.5-3°C / min to 680-750°C and keep it warm for 1-2 hours;

[0016] Step 3 Add CaCO 3 with TiO 2 Put it into a ball mill jar and add deionized water for ball milling, the ball milling time is 2 to 3 hours, and then dry;

[0017] Step 4: Raise the temperature of the dried mixture to 1280-1320°C at 3-5°C / min, and keep it warm for 2-3 hours;

[0018] Step 5 Put the two pre-burned materials into a ball mill tank and add deionized water for ball milling. The ball milling time is 2 to 3 hours, and then dry;

[0019] The 6th step uses the mass fraction to be 6~8% polyvinyl alcohol solution as binding agent, and the addition amount of binding agent is 8~10% of the mass of the mixture to be granulated...

example 1

[0022] 3ZnO·B 2 o 3 with CaTiO 3 The preparation of the composite powder:

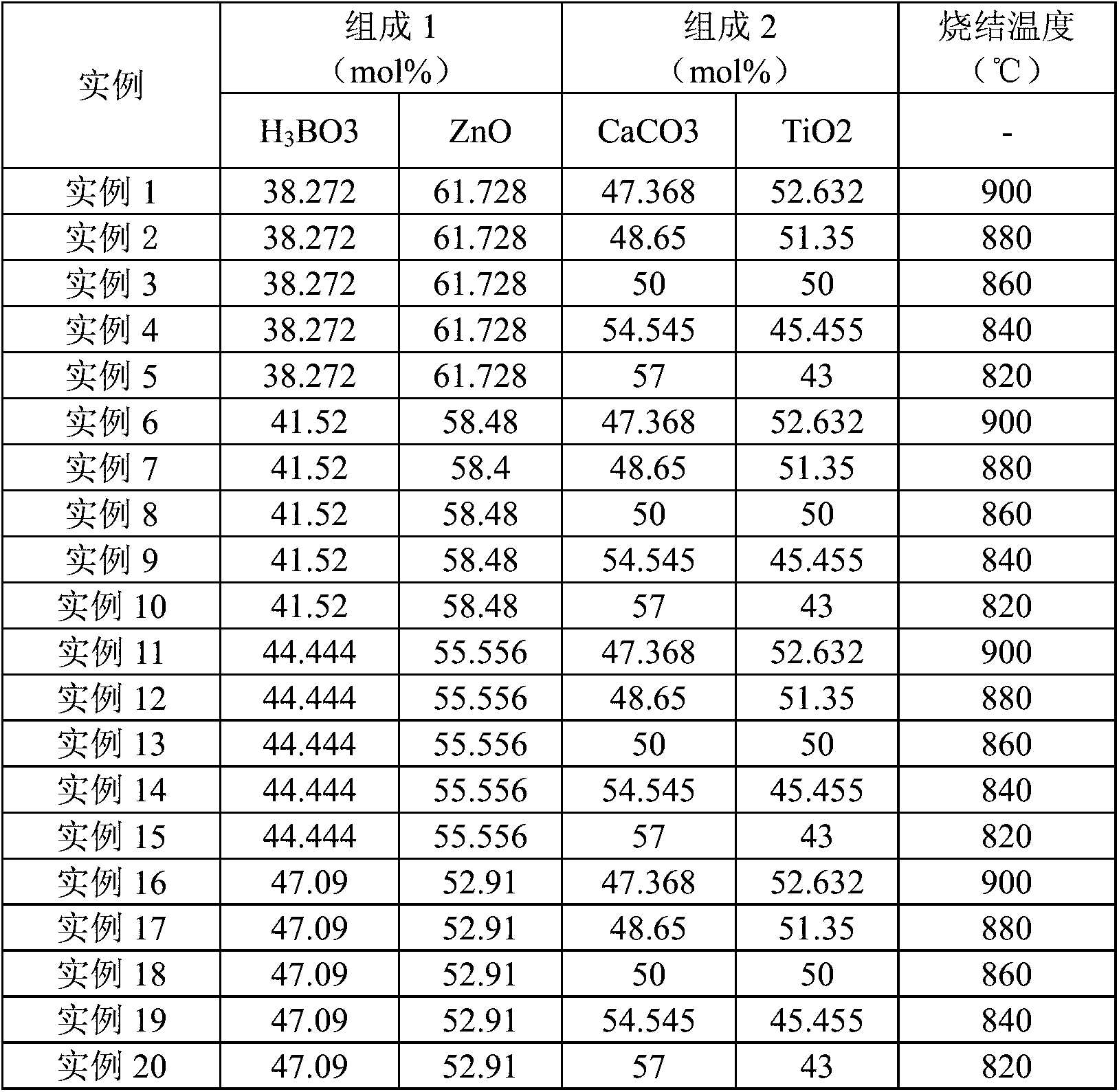

[0023] 1. H 3 BO 3 Mix with ZnO according to the ratio in Table 1, the total mass is 400 grams, grind it in an agate mortar for about 1 hour until mixed evenly, and put it in a 500ml corundum crucible.

[0024] 2. Put the corundum crucible with uniformly mixed oxides into the bell furnace, raise it from room temperature to 750°C at a speed of 3°C / min, and keep it warm for 1 hour. The pre-fired material is ground into powder with a mortar.

[0025] 3. Add CaCO 3 with TiO 2 According to the ingredients in Table 1, the total mass is 40 grams, and an appropriate amount of deionized water is added to a ball mill tank equipped with agate balls to mill for 2 hours. After discharge, it is dried at 110°C and sieved with a 60-mesh sieve.

[0026] 4. Put the powder sieved in step 3 into a 100ml corundum crucible and place it in a bell furnace, raise it to 1320°C at a speed of 5°C / min, and keep it warm for...

example 2~20

[0032] The raw materials and formula of each example are as shown in table 1, and its preparation method is identical with example 1.

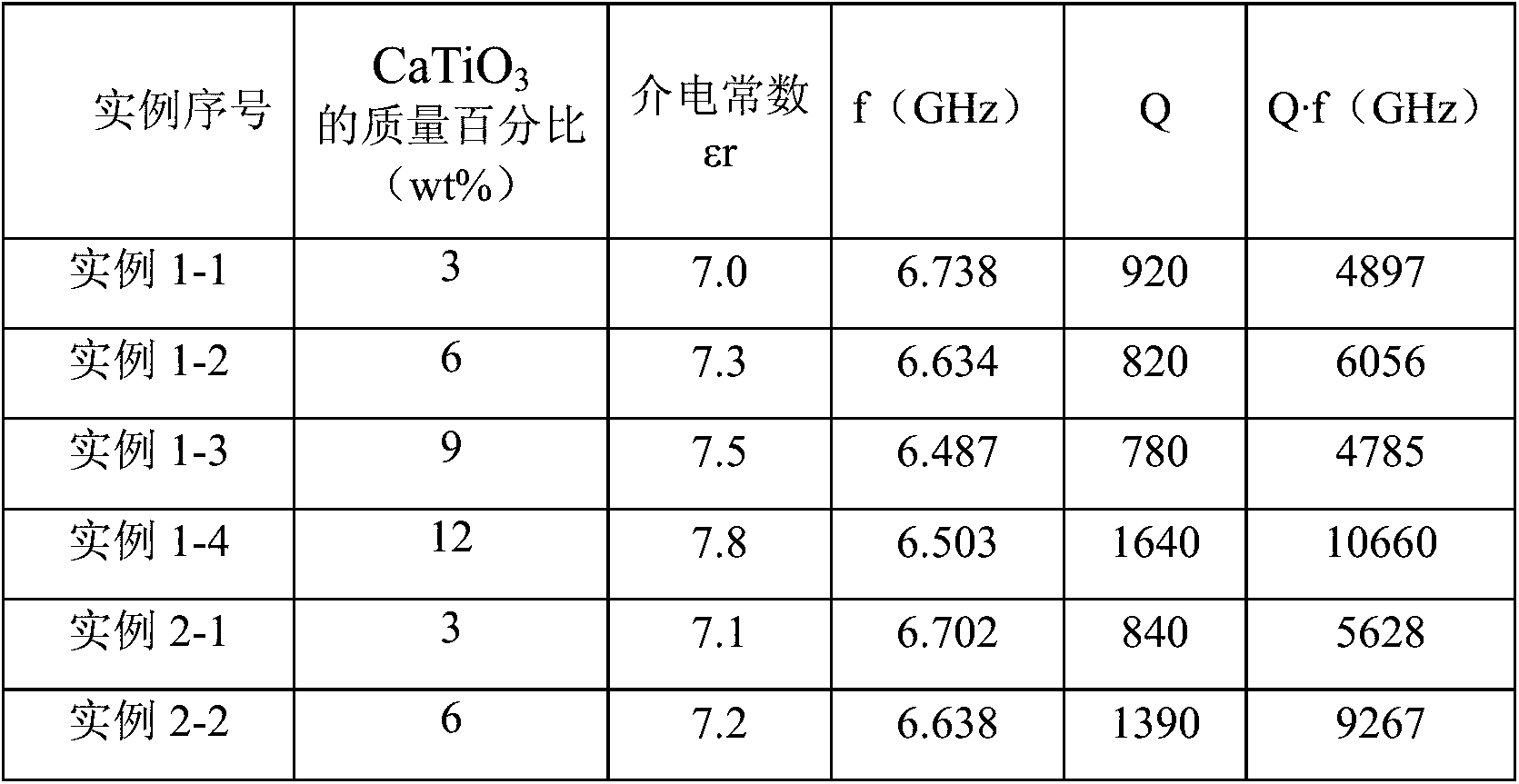

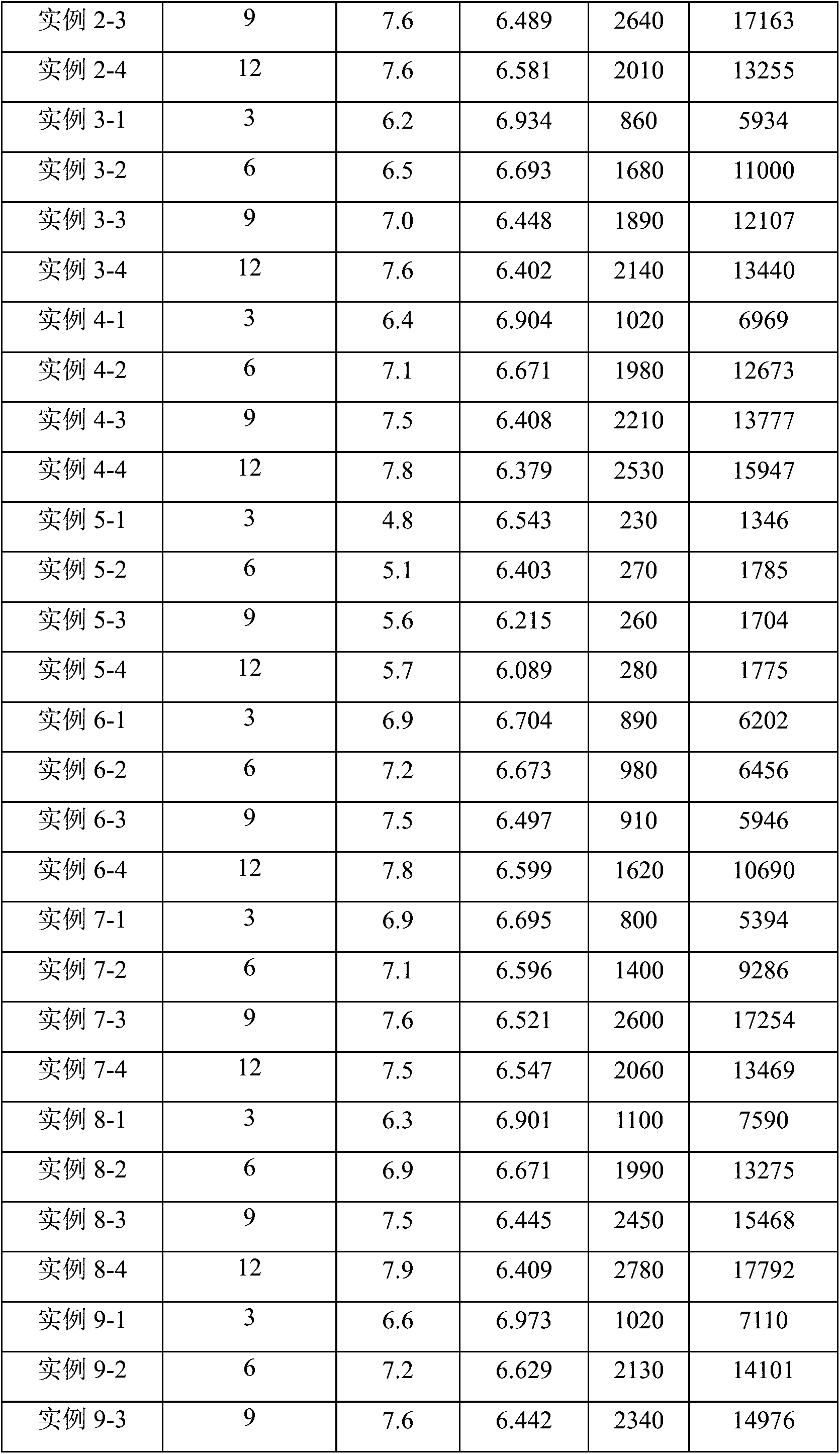

[0033] The dielectric properties of the above experimental samples were measured with an Agilent E5701C network analyzer, and the results are shown in Table 2.

[0034] (Note: CT is CaTiO 3 , wt% is the percentage of the total mass of mixed powder. Each example is further divided into four small examples, and the difference between each small example is that the mass percentages of CT are 3%, 6%, 9% and 12% respectively. )

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com