Synthetic method of pore size-adjustable nanometer mesoporous CuAl2O4 spinel

A nano-mesoporous and synthetic method technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., can solve the problems of low specific surface area and porosity, non-adjustable pore diameter, complicated process, etc., and achieve product phase purity, The effect of controllable aperture and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

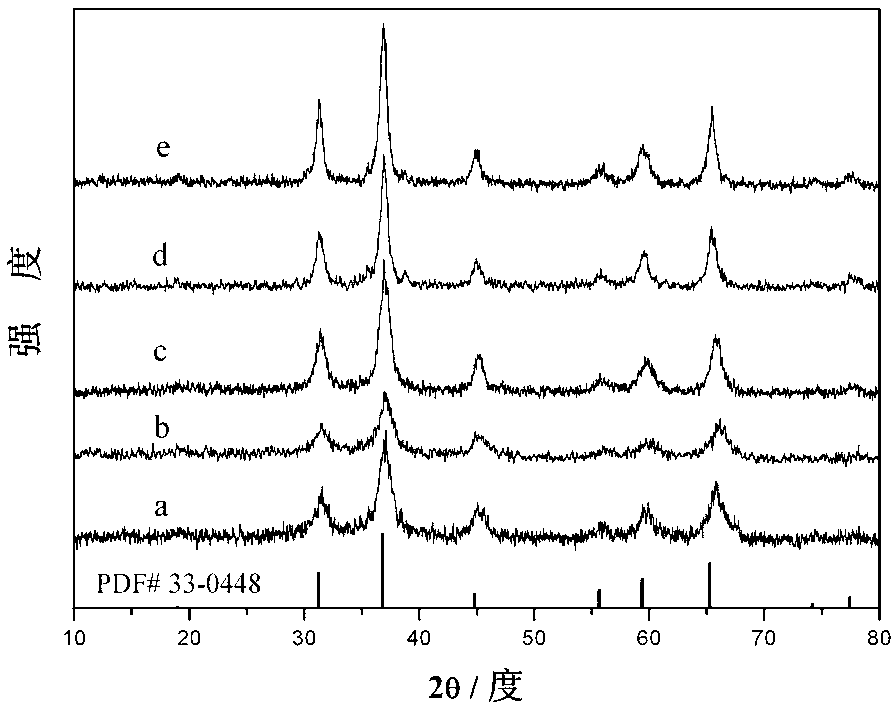

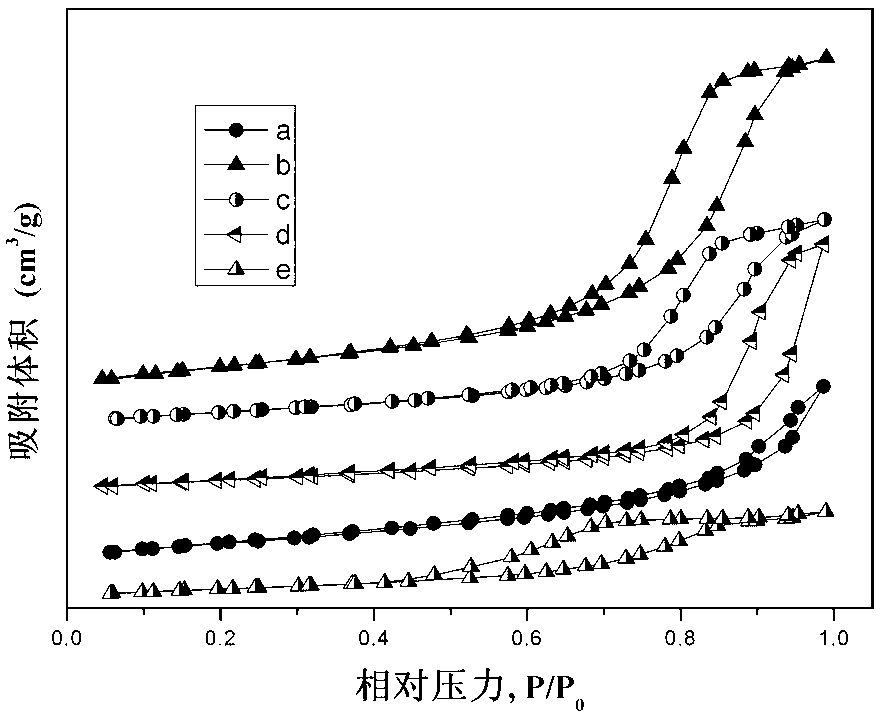

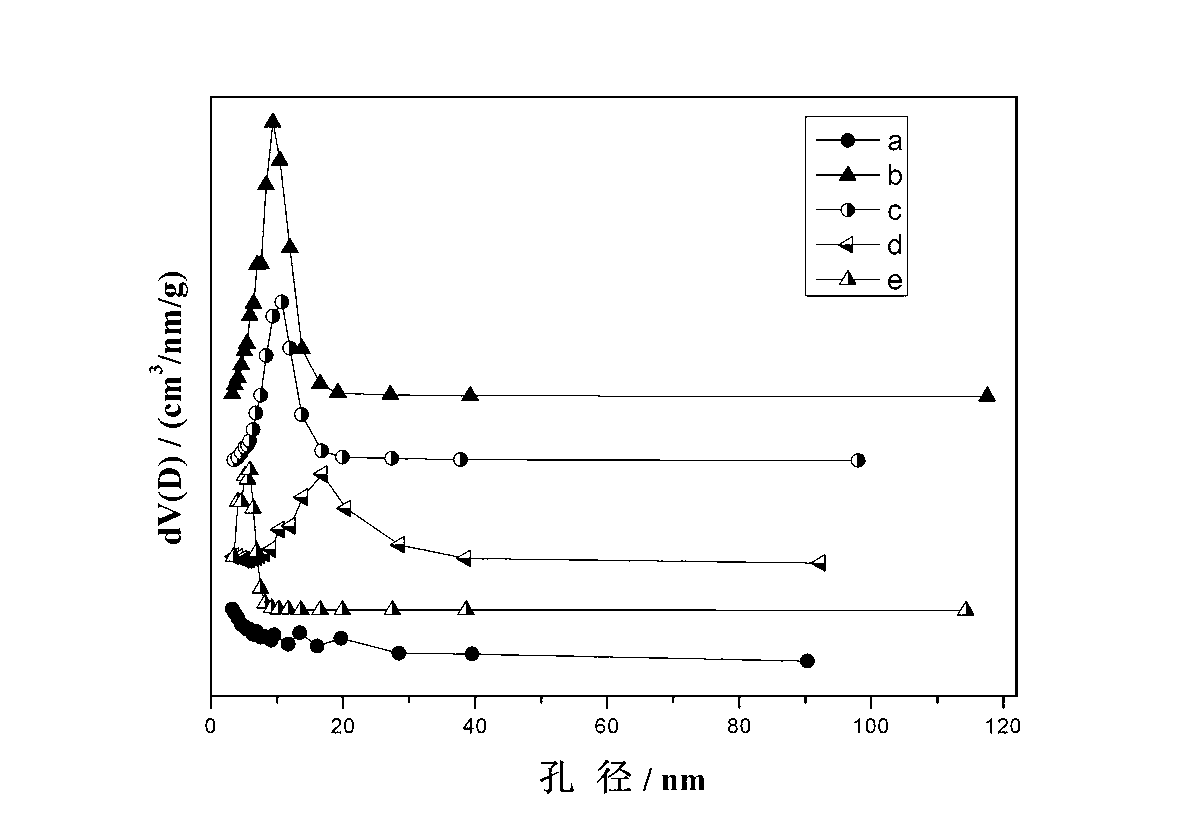

Embodiment 1

[0016] Weigh 3.57 g of n-butylamine and 1.56 g of n-dodecyl alcohol and dissolve it in 20 mL of absolute ethanol to form a mixed solution, add the mixed solution into a three-necked flask filled with 120 mL of distilled water, and then add 6.04 g of Cu( NO 3 ) 2 ·3H 2 O and 18.76 g Al(NO 3 ) 3 9H 2 O, stir well until a uniform and stable mixed solution is formed, then add 25% to 28% concentrated ammonia water drop by drop to adjust the pH of the solution to about 4.0, at this time, a sky blue precipitate appears in the solution, and finally the temperature of the system is raised by an oil bath To 80 °C, reflux at constant temperature for 24 h under full stirring, then cool to room temperature, centrifuge and wash the precipitate with distilled water and absolute ethanol three times, and then dry at 100 °C for 12 h to obtain the precursor. Finally, the precursor was calcined in a muffle furnace at 800 °C for 2 h to obtain mesoporous CuAl 2 o 4 Sample a. Mesoporous CuAl...

Embodiment 2

[0018] The preparation steps are the same as in Example 1, and 3.57 g of n-butylamine and 1.56 g of n-dodecyl alcohol are dissolved in 20 mL of absolute ethanol to form a mixed solution, and the mixed solution is added to a three-necked flask with 80 mL of distilled water, and then added to the 6.04 g Cu(NO 3 ) 2 ·3H 2 O and 18.76 g Al(NO 3 ) 3 9H 2 O, fully stir until a uniform and stable mixed solution is formed, then add 25% to 28% concentrated ammonia water drop by drop to adjust the pH of the solution to about 4.0, at this time, a sky blue precipitate appears in the solution, and finally fully stir under 80 ℃ oil After cooling to room temperature for 24 h, the precipitate was centrifuged, washed three times with distilled water and absolute ethanol, and then dried at 100 °C for 12 h to obtain the precursor. Finally, the precursor was calcined in a muffle furnace at 800 °C for 2 h to obtain mesoporous CuAl 2 o 4 Sample b. Mesoporous CuAl 2 o 4 The specific surfac...

Embodiment 3

[0020] The preparation steps are the same as in Example 1. Weigh 3.57 g of n-butylamine and 1.56 g of n-dodecyl alcohol and dissolve them in 20 mL of absolute ethanol to form a mixed solution. The mixed solution is added to a three-necked flask with 60 mL of distilled water, and then added to it 6.04 g Cu(NO 3 ) 2 ·3H 2 O and 18.76 g Al(NO 3 ) 3 9H 2O, fully stir until a uniform and stable mixed solution is formed, then add 25% to 28% concentrated ammonia water drop by drop to adjust the pH of the solution to about 4.0, at this time, a sky blue precipitate appears in the solution, and finally fully stir under 80 ℃ oil After cooling to room temperature for 24 h, the precipitate was centrifuged, washed three times with distilled water and absolute ethanol, and then dried at 100 °C for 12 h to obtain the precursor. Finally, the precursor was calcined in a muffle furnace at 800 °C for 2 h to obtain mesoporous CuAl 2 o 4 Sample c. Mesoporous CuAl 2 o 4 The specific surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com