Preparation method and device of high-volume fraction and high-intensity aluminum silicon carbide composite material

A technology of high volume fraction and aluminum silicon carbide, which is applied in the field of high strength aluminum silicon carbide composite materials to prepare high volume fraction, can solve the problems of uneven grain distribution and uncontrollable alloy grain size, and achieve high density, Effect of improving mechanical properties and thermophysical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

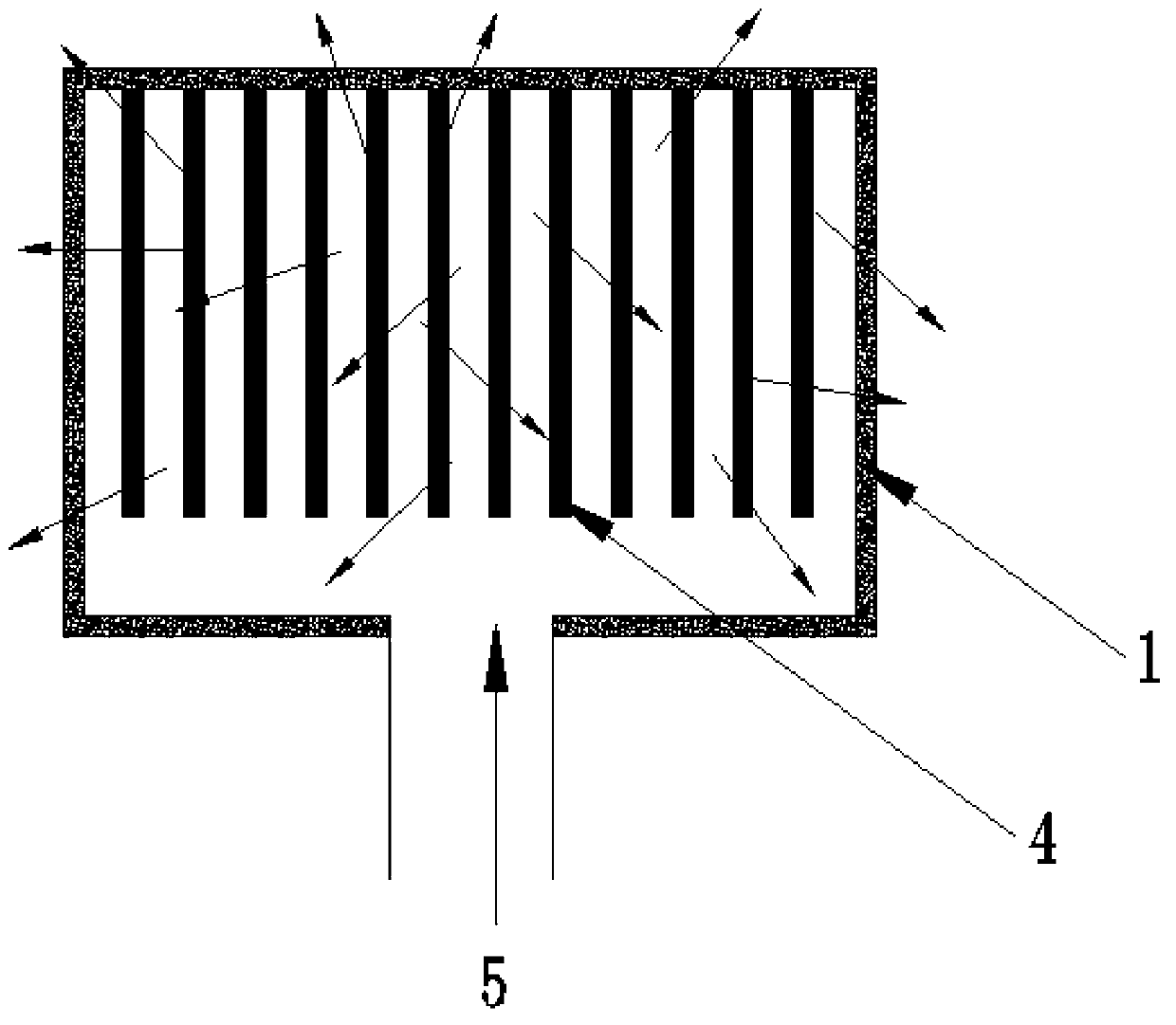

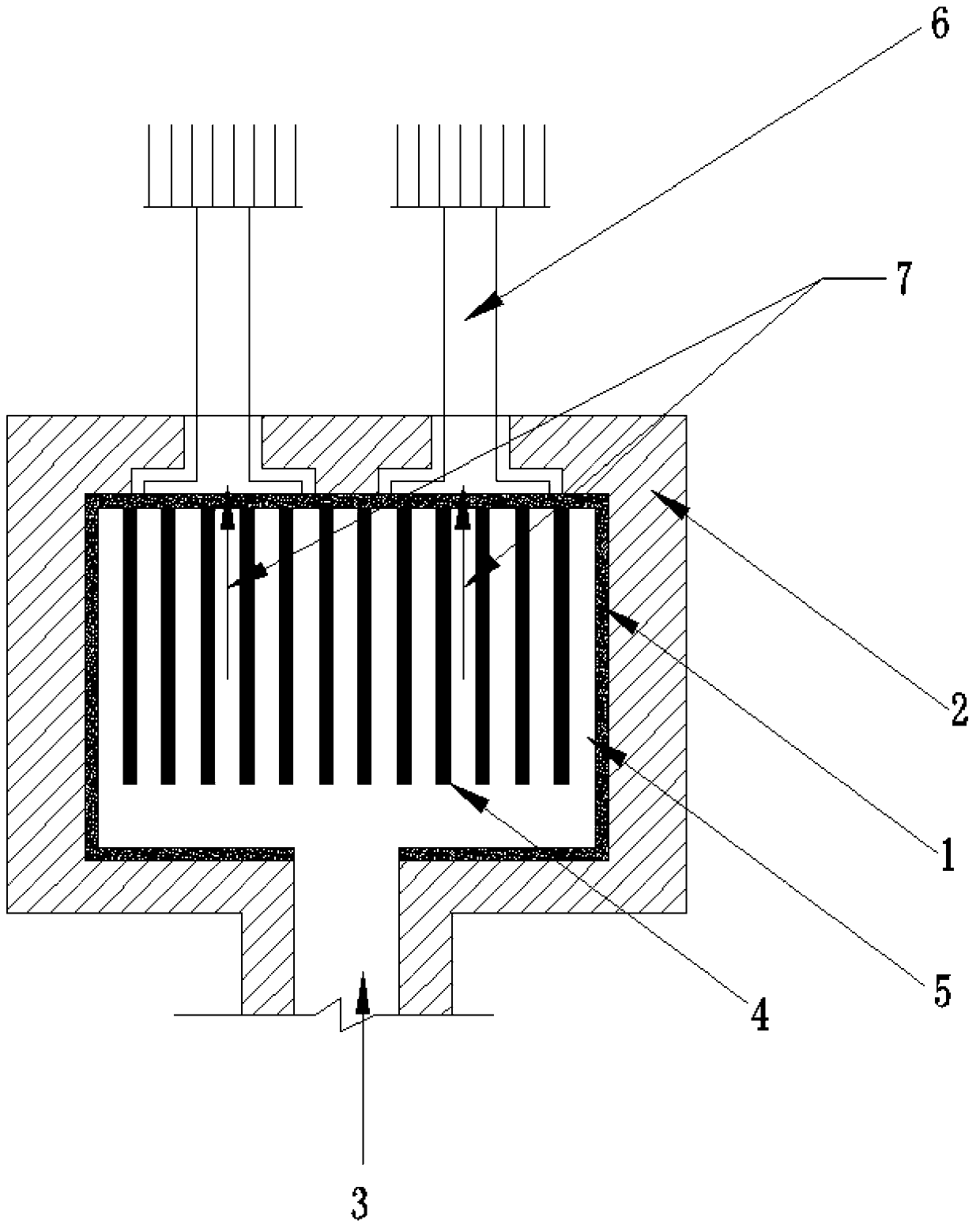

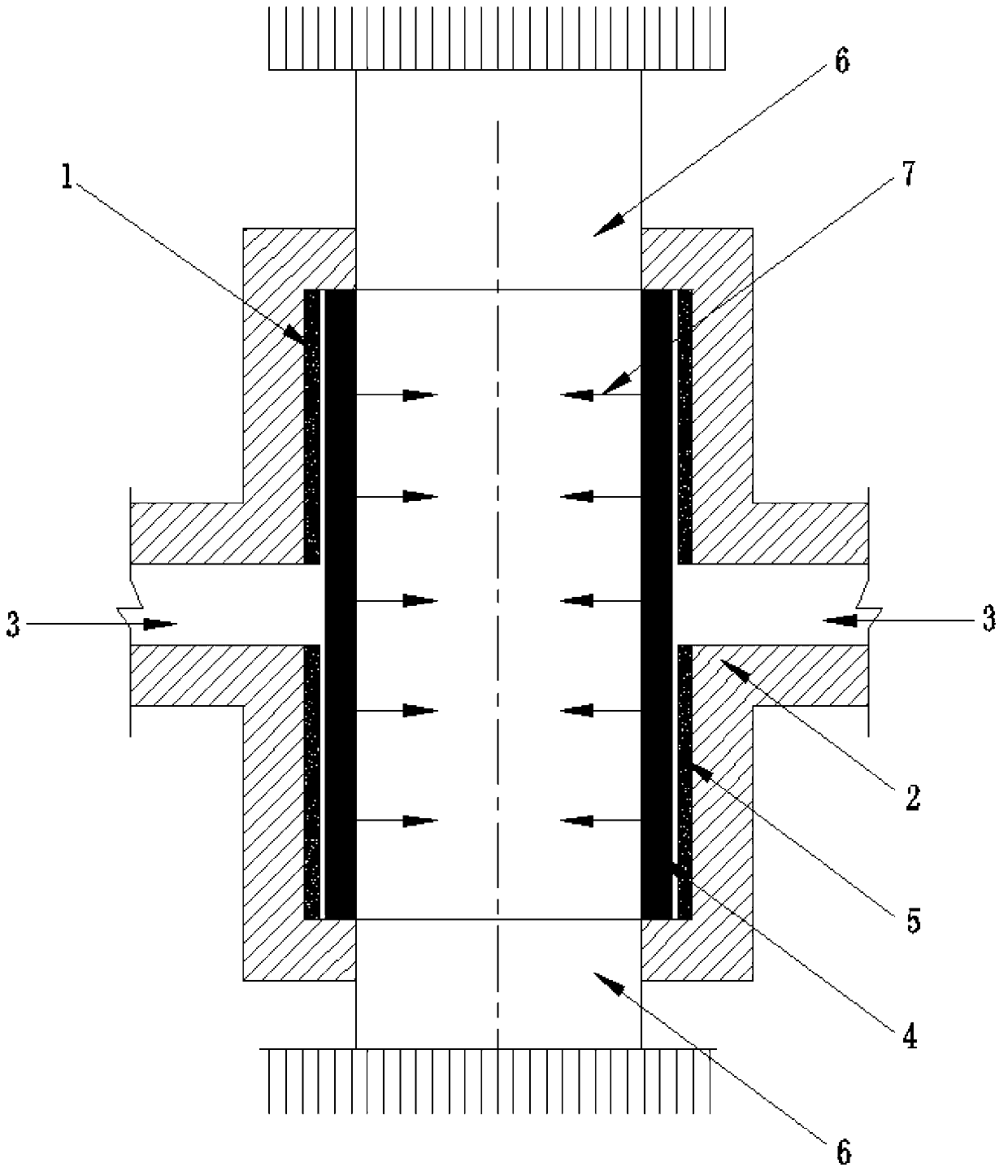

[0030] Surface-treat the rectangular silicon carbide porous preform with a porosity of 37% and a thickness of 15mm, and then install the mold; place the mold with the porous silicon carbide preform in a vacuum pressure infiltration furnace, and evacuate until the pressure in the furnace is 10Pa , replace the atmosphere in the furnace with argon, raise the temperature to 750°C, and keep it warm at 750°C for 2 hours; turn on the vacuum system, degas for 20 minutes at a temperature of 750°C, and a pressure of 15Pa in the furnace; add aluminum melt, and add gas and liquid outside Under mixing pressure, the aluminum melt is infiltrated into the porous silicon carbide preform, and the temperature is kept at 750° C. for 1 minute during aluminizing. The heat pipe is in close contact with one end of the mold, and the remaining surface of the mold is wrapped with an insulating layer; the temperature of the end surface of the mold is cooled at a rate of 600°C / min, and the cooling rate of ...

Embodiment 2

[0032] Surface treatment the porous SiC preform with a porosity of 50% and a thickness of 20mm and install the mold; place the mold with the porous SiC preform in a vacuum pressure infiltration furnace, and evacuate until the pressure in the furnace is 10Pa , replace the atmosphere in the furnace with argon, raise the temperature to 750°C, and keep warm at 750°C for 2 hours; turn on the vacuum system, degas for 1 minute at a temperature of 750°C and a pressure of 0.1Pa in the furnace; add aluminum melt, and add gas outside Under the liquid mixing pressure, the aluminum melt is infiltrated into the porous silicon carbide preform, and the temperature is maintained at 750°C for 2 minutes during aluminizing. The heat pipe is in close contact with one end of the mold, and the remaining surface of the mold is wrapped with an insulating layer; the temperature of the end surface of the mold is cooled at a rate of 400°C / min, and the cooling rate of the rest of the mold is less than 100°...

Embodiment 3

[0034]The porosity is 25%, the silicon carbide porous preform with thickness of 15mm is subjected to surface treatment, and then molded; the mold with porous silicon carbide preform is placed in a vacuum pressure infiltration furnace, and the vacuum is evacuated until the pressure in the furnace is 1.0 Pa, the atmosphere in the replacement furnace is argon, the temperature is raised to 700°C, and the temperature is kept at 700°C for 4 hours; the vacuum system is turned on, and the gas is degassed at 700°C and 50Pa in the furnace for 30 minutes; Under the pressure of liquid mixing, the 102 alloy aluminum melt is infiltrated into the porous silicon carbide preform, and the temperature is maintained at 700 ° C for 1 minute during aluminizing. The heat pipe is in close contact with one end of the mold, and the remaining surface of the mold is wrapped with an insulating layer; the temperature of the end surface of the mold is cooled at a rate of 800°C / min, and the cooling rate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com