Rare earth containing H profile steel with high strength and high toughness and production method thereof

A high-strength, high-toughness, production method technology, applied to the improvement of process efficiency, metal rolling, etc., can solve the problems of limited toughness improvement, large toughness fluctuations, unstable mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Raw materials by weight percentage are: 90% of blast furnace molten iron and 10% of high-quality steel scrap.

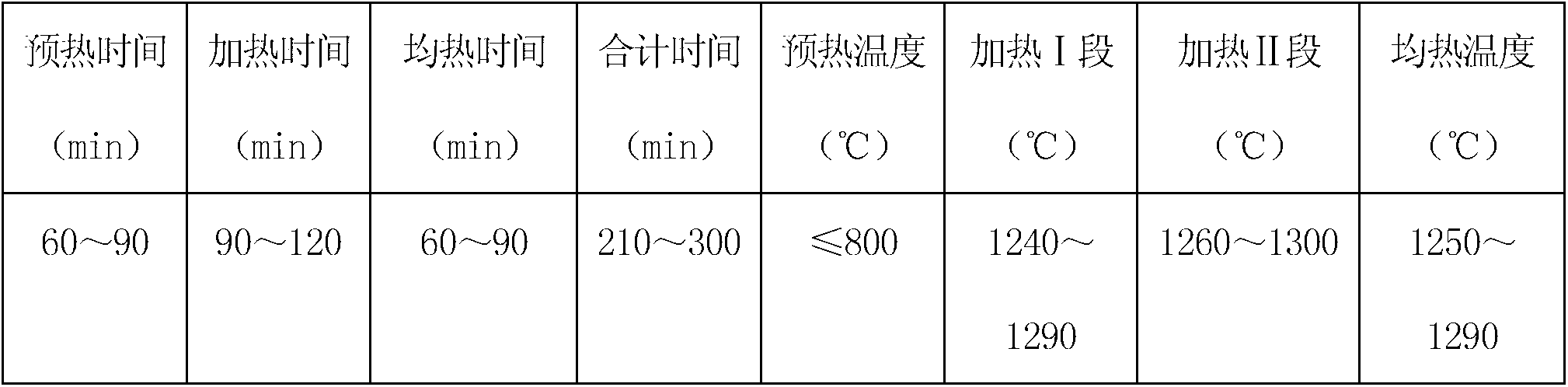

[0038] The production process is as follows: molten iron pretreatment→top-bottom combined blowing converter smelting→LF furnace refining→VD vacuum treatment→square casting→cutting→casting heating→high-pressure water phosphorus removal→BD1 breaking→BD2 rolling→high-pressure water Phosphorus removal→CCS universal rolling→straightening→cooling→flaw detection→sawing.

[0039] The specific production process is briefly described as follows:

[0040] 90 tons of blast furnace molten iron was pretreated with "metal magnesium powder" for desulfurization and deoxidation, so that the S content in the molten iron was reduced to (weight percent) below 0.010%;

[0041] Mix the 90 tons of pretreated molten iron into a 100-ton top-bottom combined blown converter, add 10 tons of high-quality steel scrap, and then use the single slag process for smelting. The final slag basici...

Embodiment 2

[0061] The ratio of raw materials, production process, etc. and other process indicators of embodiment 2 are all the same as embodiment 1, except that the chemical composition content (% by weight) of its casting failure is specifically shown in table 3:

[0062] The bad chemical composition detection result (weight %) of table 3 casting

[0063] C Si mn P S Cr Ni V Cu Ti Al RE 0.10 0.23 1.55 0.015 0.007 0.50 0.33 0.13 0.009 0.013 0.027 0.0011

[0064] The test results of mechanical properties of H plow steel are shown in Table 4.

[0065] Table 4H mechanical performance test results of plow steel

[0066] R e1 (MPa) R m (MPa) R e1 / R m A(%) a KV (transverse direction, -40℃, J / cm 2 ) organize 535 722 0.74 26.5 119 ferrite + pearlite

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com