Microencapsulation ammonium polyphosphate fire retardant and preparation method thereof

An ammonium polyphosphate and microencapsulation technology, which is applied in microcapsule preparation, microsphere preparation, textile and papermaking, etc., can solve the problems of increasing water content of flame retardant coating, reducing hygroscopicity of ammonium polyphosphate, and surface wet sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

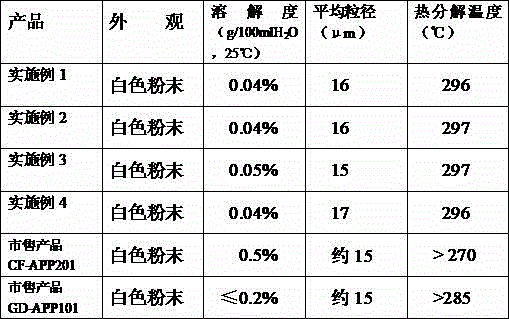

Examples

Embodiment 1

[0023] Raw material ratio: crystal phase II ammonium polyphosphate (APP II) 100 grams, melamine 4 grams, diphenylmethane diisocyanate (MDI) 11.1 grams, triphenylmethane triisocyanate 0.42 grams, dicyclohexylcarbodiimide 5.2 grams , 0.55 grams of trimethylolethane, 121 grams of acetone, and 27.4 grams of toluene.

[0024] Process method:

[0025] (1) Add melamine and crystalline phase II ammonium polyphosphate (APPⅡ) into the ball mill, heat to 240-250°C, grind for 80-100 minutes, then cool down to 40-45°C; make the surface of APPⅡ covered with a layer of melamine membrane;

[0026] (2) Add APPⅡ and acetone coated with melamine film into the mixing kettle for stirring and mixing;

[0027] (3) Homogeneously emulsify the above mixed material with a homogeneous emulsifier to form a suspension with a particle size of 10-15 μm;

[0028] (4) Put the above-mentioned homogenized suspension into the reaction kettle, and then add toluene, diphenylmethane diisocyanate (MDI), triphenylm...

Embodiment 2

[0031] Raw material ratio: crystal phase II ammonium polyphosphate (APP II) 101 grams, melamine 4.4 grams, diphenylmethane diisocyanate (MDI) 11.4 grams, triphenylmethane triisocyanate 0.43 grams, dicyclohexylcarbodiimide 5.4 grams , 0.7 gram of trimethylolethane, 124 gram of acetone, 28.6 gram of toluene; Process method is with embodiment 1.

Embodiment 3

[0033] Raw material ratio: crystal phase II ammonium polyphosphate (APP II) 101.8 grams, melamine 4.3 grams, diphenylmethane diisocyanate (MDI) 11.2 grams, triphenylmethane triisocyanate 0.48 grams, dicyclohexylcarbodiimide 5.1 grams , 0.75 gram of trimethylolethane, 123 gram of acetone, 28 gram of toluene; Process method is with embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com