Lithium carbonate modified cerium barium zirconate proton conductor material and preparation method thereof

A technology of cerium barium zirconate and proton conductor, which is applied in the field of lithium carbonate modified cerium barium zirconate proton conductor material and its preparation, can solve the problems of sintering densification difficulty, material performance degradation, etc., and achieve improved electrical performance and stability , Improve sintering performance, increase the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

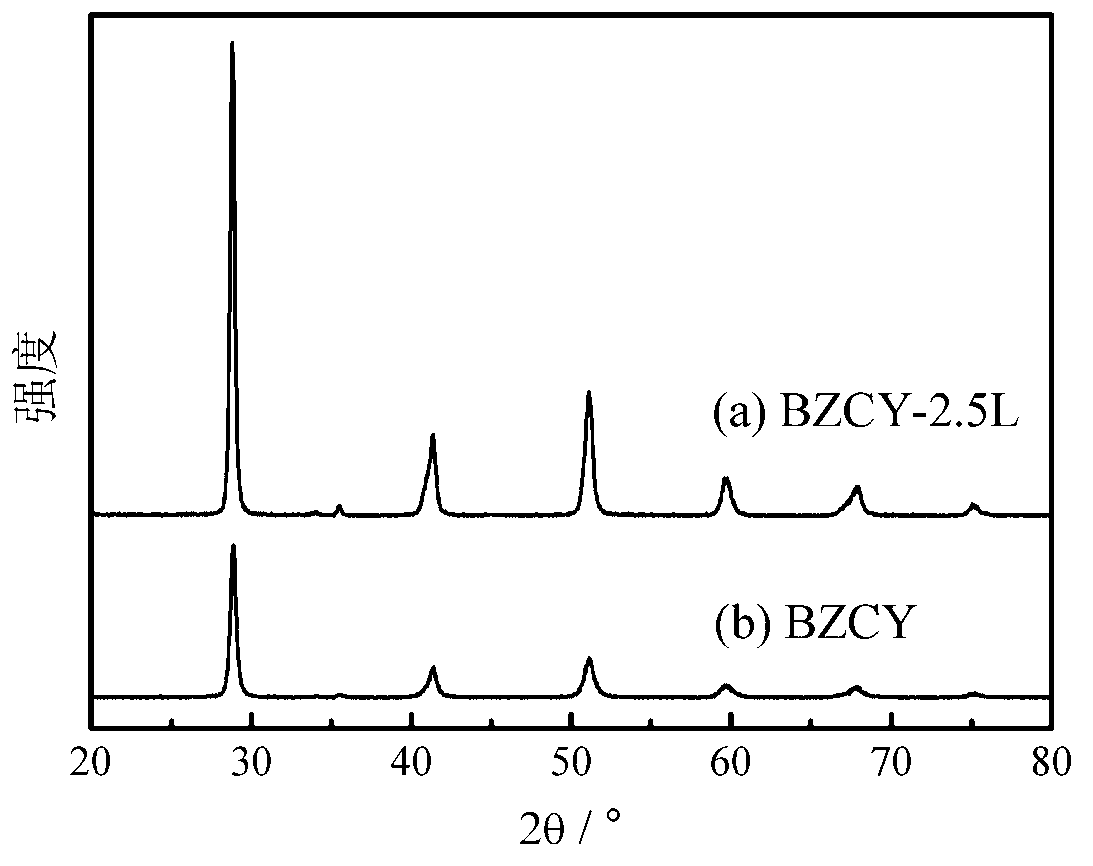

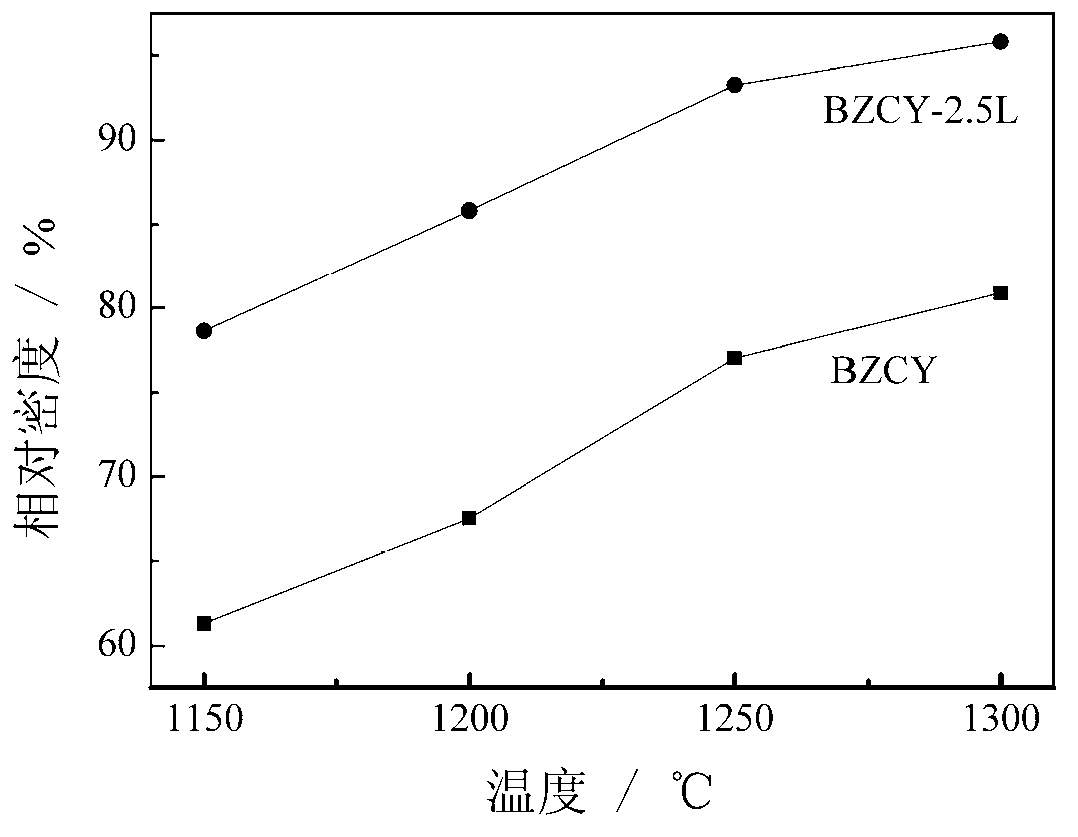

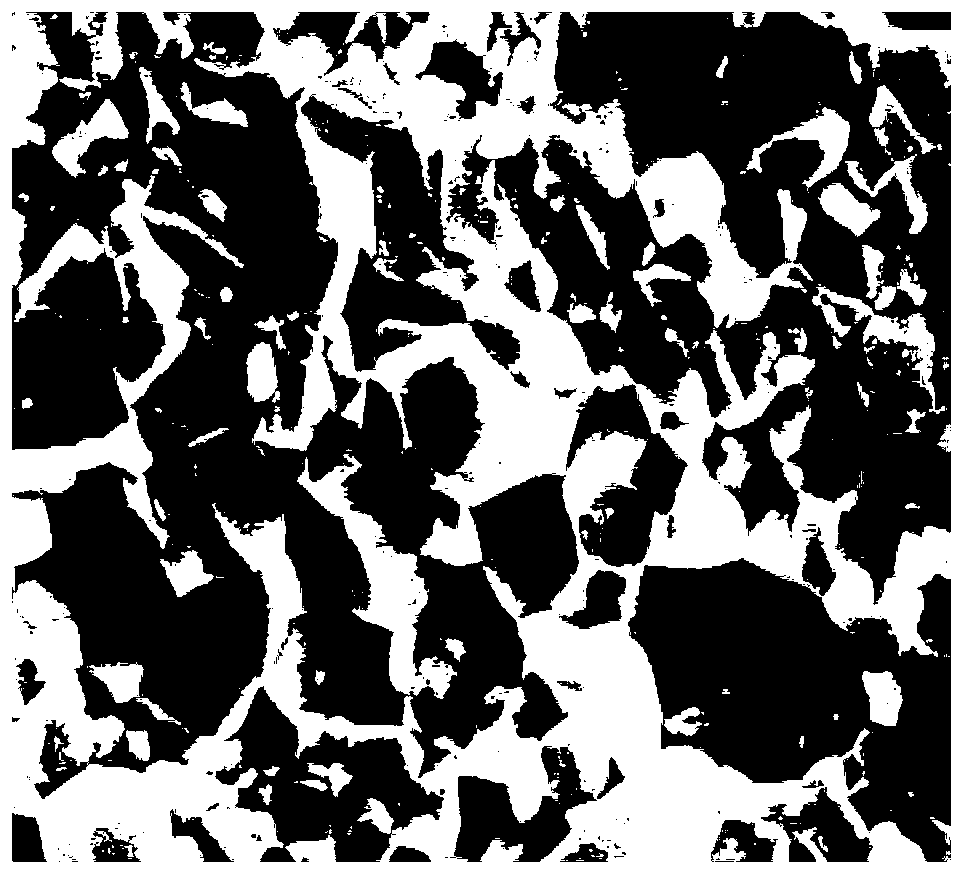

[0020] According to BaCe 0.7 Zr 0.1 Y 0.2 o 3-δ stoichiometric ratio, take 1 mole of Ba(NO 3 ) 2 , 0.7 Mole CeWO 3 ) 3 ·6H 2 O, 0.1 mole Zr(NO 3 ) 4 ·5H 2 O, 0.2 mole Y (NO3 ) 3 ·6H 2 O, mix according to the total metal ions: EDTA: citric acid (molar ratio) = 1:1.5:1, dissolve in 500lnL deionized water, use ammonia water to adjust the pH value of the solution to 8, heat and stir to evaporate the water continuously to obtain a viscous shape The light yellow gel is obtained by burning the organic matter in a stainless steel reaction vessel to obtain off-white powder, then pre-calcined at 240 ° C, kept for 5 hours, and finally calcined at 1000 ° C, kept for 5 hours, to prepare a pure phase BaCe 0.7 Zr 0.1 Y 0.2 o 3-δ (BZCY) Pale yellow powder. Add 2.5% lithium carbonate by mass to the base powder, and use absolute ethanol as the medium for ball milling and mixing for 6 hours. After drying, grinding, and sieving, weigh 0.7 grams of the mixed electrolyte powder an...

Embodiment 2

[0023] According to BaCe 0.7 Zr 0.1 Y 0.2 o 3-δ stoichiometric ratio, take 1 mole of Ba(NO 3 ) 2 , 0.7 mol CeWO 3 ) 3 ·6H 2 O, 0.1 mole Zf(NO 3 ) 4 ·5H 2 O, 0.2 mole Y (NO 3 ) 3 ·6H 2 O, mix according to total metal ion: EDTA: citric acid (molar ratio) = 1:2:1, dissolve in 500mL deionized water, use ammonia water to adjust the pH value of the solution to 6, heat and stir to make the water evaporate continuously to obtain a viscous shape The light yellow gel is obtained by burning organic matter in a stainless steel reaction vessel to obtain an off-white powder, then pre-calcined at 240°C for 5 hours, and finally calcined at 1050°C for 5 hours to prepare a pure-phase BZCY light yellow powder body. Add lithium carbonate with a mass percentage of 5% to the matrix powder, mix and ball mill with absolute ethanol for 6 hours, then dry, grind, and sieve, weigh 0.7 grams of the mixed electrolyte powder and pour it into a 12mm mold Carry out dry pressing molding in the m...

Embodiment 3

[0026] According to BaCe 0.7 Zr 0.1 Y 0.2 o 3-δ stoichiometric ratio, take 1 mole of Ba(NO 3 ) 2 , 0.7 mol CeWO 3 ) 3 ·6H 2 O, 0.1 mole Zr(NO 3 ) 4 ·5H 2 O, 0.2 mole YWO 3 ) 3 ·6H 2 O, mix according to total metal ion: EDTA: citric acid (molar ratio)=1:1.5:1, dissolve in 500mL deionized water, use ammonia water to adjust the pH value of the solution to 7, heat and stir to make the water evaporate continuously to obtain a viscous shape The light yellow gel is obtained by burning organic matter in a stainless steel reaction vessel to obtain off-white powder wood, then pre-calcined at 240°C for 5 hours, and finally calcined at 1100°C for 5 hours to prepare a pure phase of BZCY light yellow Powder. Add 7% lithium carbonate by mass to the matrix powder, mix and ball mill for 6 hours with absolute ethanol as the medium, then dry, grind and sieve, weigh 0.7 g of the mixed electrolyte powder and pour it into a 15mm mold Carry out dry pressing molding, the pressure is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com